Optional robart retractable landing gear, Additional items required – Top Flite TOPA0705 User Manual

Page 4

4

Depending on your choice of receiver and the number

of channels you will be using you may have to use

“Y” harnesses on the aileron, flaps and elevator.

(FUTM4130)

❍ 1500 mAh NiCad receiver battery or equivalent

(FUTM1285).

❍ 2 - Heavy duty switch harness (FUTM4385).

❍ 2 - Ernst Charge Receptacle (ERNM3001).

❍ 2 - 1" Servo arms

❍ 1 - 2" Servo arm

(There are a number of options for servo arms. We

used the Du-Bro Super Strength Arms. (DUBM6670)

This package includes eight servo arms, including the

two needed for this model).

ENGINE RECOMMENDATIONS

The recommended engine size range for the P-40 is

43cc to 55cc [2.6 - 3.3 cu in] two-stroke gasoline engine.

We used the DLE

™

55 engine for our model. We have

provided instructions and hardware for the Fuji-Imvac

™

43 EI (FJIG134) and the DLE 55 (DLEG0055). Other

engines can also be used but you may need to make

modifi cations for mounting those engines.

OPTIONAL ROBART

RETRACTABLE LANDING GEAR

Robart makes a very realistic, high quality, scale landing

gear for the P-40. This landing gear rotates just the

same as the full scale airplane providing a very realistic

operation. This is a tremendous addition to the airplane.

If you choose to use them you will need the following.

❍ 100 Degree retract large scale (ROBQ1665)

❍ 157VR Large Air Control Kit (ROBQ2305)

❍ 169 Pressure Tubing 10' Red/Purple

(ROBQ2369)

❍ #160LWC LH Offset Pneumatic Tail Wheel

(ROBQ2225)

ADDITIONAL ITEMS REQUIRED

REQUIRED HARDWARE & ACCESSORIES

This is the list of hardware and accessories required

to fi nish the P-40.

Order numbers are provided in

parentheses.

❍ R/C foam rubber (1/4" [6mm] - HCAQ1000, or

1/2" [13mm] - HCAQ1050)

❍ 3' [900mm] gasoline fuel tubing (GPMQ4135)

❍ 1 oz. [30g] Thin Pro

™

CA (GPMR6002)

❍ 1 oz. [30g] Medium Pro CA+ (GPMR6008)

❍ Pro 30-minute epoxy (GPMR6047)

❍ Pro 6-minute epoxy (GPMR6045)

❍ Silver solder w/fl ux (STAR2000)

❍ Hobbico

®

Soldering Iron 60 Watt (HCAR0776)

❍ #1 Hobby knife (HCAR0105)

❍ #11 blades (5-pack, HCAR0211)

❍ R/C-56 canopy glue (JOZR5007)

❍ Epoxy brushes (6, GPMR8060)

❍ Mixing sticks (50, GPMR8055)

❍ Mixing cups (GPMR8056)

❍ Masking tape (TOPR8018)

❍ Threadlocker thread locking cement

(GPMR6060)

❍ Denatured alcohol (for epoxy clean up)

❍ Panel Line Pen (TOPQ2510)

❍ Rotary tool such as Dremel

®

❍ Rotary tool reinforced cut-off wheel

(GPMR8200)

❍ Drill bits: 1/16" [1.6mm], 1/8" [3.2mm], 5/64"

[2mm], 3/32" [2.4mm], 7/64" [2.8mm}, 3/16"

[4.8mm], 5/16" [8mm], 1/4" [6.4mm].

❍ Du-Bro Fuel Line Barb 1/8" (DUBQ0670)

OPTIONAL SUPPLIES & TOOLS

Here is a list of optional tools mentioned in the manual

that will help you build the P-40.

❍ 21

st

Century

®

sealing iron (COVR2700)

❍ 21

st

Century

®

iron cover (COVR2702)

❍ 2 oz. [57g] spray CA activator (GPMR6035)

❍ 4 oz. [113g] aerosol CA activator (GPMR634)

❍ Epoxy brushes (6, GPMR8060)

❍ Mixing sticks (50, GPMR8055)

❍ Mixing cups (GPMR8056)

❍ Denatured alcohol (for epoxy clean up)

❍ Panel Line Pen (TOPQ2510)

❍ Rotary tool such as Dremel

®

❍ Rotary tool reinforced cut-off wheel

(GPMR8200)

IMPORTANT BUILDING NOTES

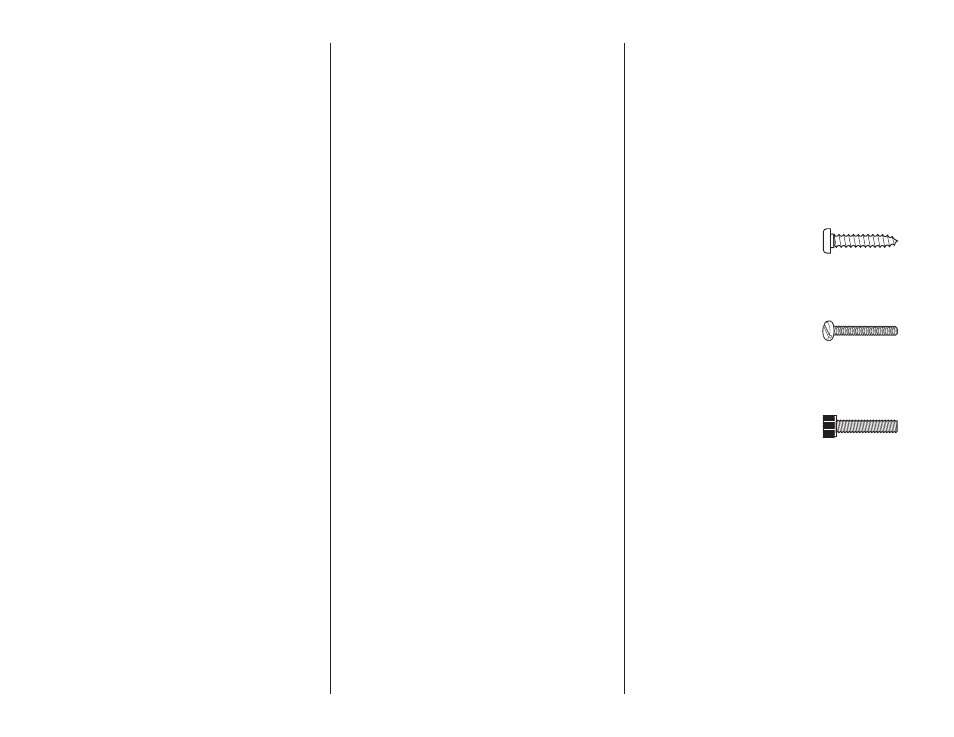

● There are three types of screws used in this kit:

Sheet Metal Screws

are designated by a number

and a length. For example #6

× 3/4" [19mm].

This is a number six screw

that is 3/4" [19mm] long.

Machine Screws

are designated by a number,

threads per inch,

and a length. For example

4-40

× 3/4" [19mm].

This is a number four screw

that is 3/4" [19mm] long with

forty threads per inch.

Socket Head Cap Screws

(SHCS)

are designated

by a number,

threads per inch

, and a length. For

example 4-40 × 3/4" [19mm].

This is a 4-40 SHCS that is

3/4" [19mm]

long with forty

threads per inch

● When you see the term

test fi t

in the instructions,

it means that you should fi rst position the part on

the assembly

without using any glue

, then slightly

modify or

custom fi t

the part as necessary for the

best fi t.

● Whenever the term

glue

is written you should rely

upon your experience to decide what type of glue

to use. When a specifi c type of adhesive works

best for that step, the instructions will make a

recommendation.

● Whenever just

epoxy

is specifi ed you may use

either

30-minute (or 45-minute) epoxy

or

6-minute

epoxy. When 30-minute epoxy is specifi ed it is

highly

recommended that you use only 30-minute

(or 45-minute) epoxy, because you will need the

working time and/or the additional strength.