Top Flite TOPA0705 User Manual

Page 23

23

❏

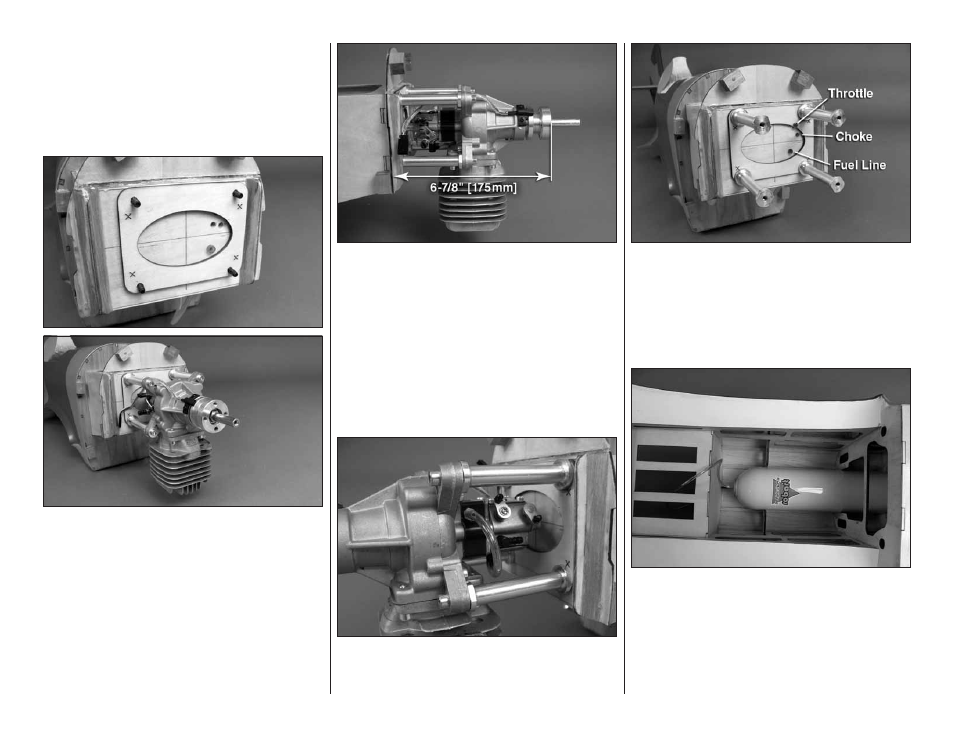

2. We have included 1/8" [3.2mm] plywood spacers

to help space different engines out the required distance

for the engine to fi t the cowl. Drill a 3/16" [4.8mm] hole

through the “+” marks on one of the plywood spacers.

It’s a good idea to fuel proof the spacer. This can be

done by brushing a coat of 6-minute epoxy thinned

with alcohol, or a coat of paint.

❏

3. Install 10-32 Ч 1" [10-32 Ч 25mm] engine mounting

bolts, fl at washers and lock washers from the back of

the fi rewall. (The mounting hardware is not included

in this kit. It should come with the engine. Most likely

the bolts with the engine are too short. You will need

to purchase four of the required bolts.

We strongly

recommend the use of 3/4 in. [19mm] fender

washers on the back side of the fi rewall

). Install

two

plywood spacers onto the bolts. Apply a drop of

threadlocker to each bolt before installing.

Note:

The

photo shows only one plywood spacer installed but two

are needed for the installation of the DLE-55.

❏

4. For reference, the distance from the front

of the firewall to the front of the drive washer is

6-7/8" [175mm].

Many modelers have their own opinions for connectors

and throttle linkage. We have provided materials for a

secure and safe throttle linkage. We have also included

a method to connect a linkage to the choke. This will

require the use of an additional servo for the choke

linkage. Some modelers may prefer a mechanical

choke linkage. Review the following procedure and

then modify it to fi t your personal preferences.

❏

5. Install a 2-56 ball link and 2-56 nuts to both the

throttle and the choke. Be sure to apply a drop of

thread-locker to the threads on the ball link.

❏

6. Make marks on the fi rewall where the throttle,

choke and fuel line will pass through. Remove the

engine from the standoffs and then drill a 3/16" [4.8mm]

hole through the fi rewall for the throttle and choke.

Drill a 1/4" [6.4mm] hole on the mark for the fuel line.

(Check the diameter of your fuel line to be sure that a

1/4" [6.4mm] hole is correct).

❏

7. Install 18" [457mm] of air line onto the end of

the air tank. Install the Robart air tank into the cradle

in the fuselage. A couple of dabs of silicone sealant

(such as Shoe Goo

®

) can be applied at the front to

hold the tank in position, but still allow it to be removed

if necessary. A plywood plate will be installed later to

secure the tank.