Install the servos and pushrods – Top Flite TOPA0210 User Manual

Page 26

INSTALL THE SERVOS AND

PUSHRODS

Make the pushrods

❏ 1. Locate the die-cut 1/8" [3.2mm] ply pushrod

brackets. Drill a 3/16" [4.8mm] hole through each

punch mark.

❏ 2. Glue the pushrod brackets to the fuselage sides

at the locations shown on the plan.

❏ 3. Install the plastic outer pushrod tube in the front

half of the fuselage for the steering pushrod as shown

on the plan. You may need to remove the fuel tank to

get the tube in place.

❏ 4. Locate three 2-56 x 36" [914mm] threaded rods.

These will be used for the nose gear steering, the

rudder and the elevator.

Install the servos in the fuselage

NOTE: Before marking any of the pushrods, connect

the servos to the receiver and electronically center

each servo.

❏ 1. Glue the die-cut 1/8" [3.2mm] ply throttle

servo mount in place in the fuselage as indicated

on the plan.

❏ 2. Glue two 1/4" x 1/4" [6.4 x 6.4mm] basswood

servo rails in place as shown on the plan. The rear

rail is glued to the notches in the fuselage doubler.

The forward rail is glued to former F-3A.

❏ 3. Mount the servos to the rails and the plywood

mount as shown on the plan.

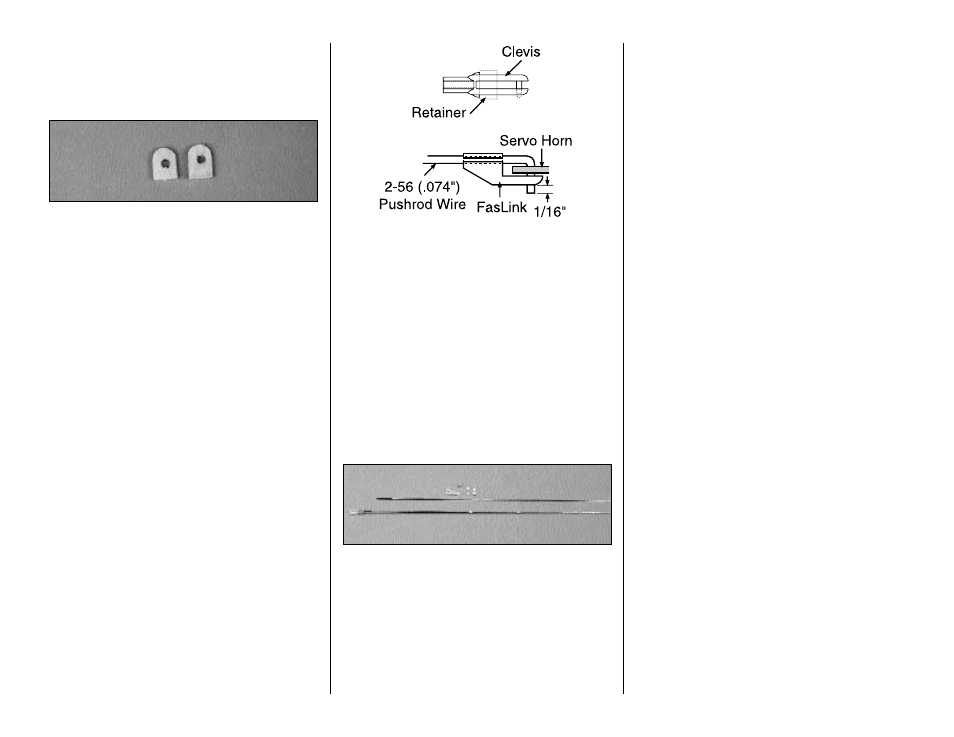

❏ 4. Slide a silicone retainer onto the rear end of a

nylon clevis. Thread the clevis 14 turns onto a 36"

wire pushrod (threaded on one end). Slide the

pushrod into the elevator pushrod tube until the

clevis pin is even with the holes in the elevator

control horn. Connect the clevis to the control horn.

❏ 5. Assemble a second wire pushrod for the rudder

pushrod tube.

❏ 6. With the elevator and rudder pushrods connected

to the control horns and the elevator and rudder

centered, mark the pushrod wires where they align

with the servo arms. Remove the pushrods, then trim

them about 1" forward of the marks.

❏ 7. Cut ten 1/8" [3.2mm] long pieces from the 12"

[305mm] plastic inner pushrod. Slide five bushings

onto each pushrod, spreading them out about 2-1/2"

apart, from the servo and the end of the pushrod. If the

bushings are tight and difficult to slide on, cut them to

a shorter length. Check the fit of both pushrods. When

you are satisfied with the fit, apply a small drop of thin

CA to each bushing to keep them in place on the

pushrod. Do not reinstall the pushrods into the tubes

until the CA has completely cured.

❏ 8. Enlarge one outside hole in the elevator and

rudder servo arms with a 5/64" bit. Make a 90 degree

bend in each of the pushrods at the point that you

marked. Cut off the excess wire, leaving about 3/8"

after the bend. Remove the clevises, then insert the

pushrods all the way into the tubes from the servo

end. Reattach the clevises and silicone retainers.

Poke the upturned wires through the servo horns

and secure them in position with nylon FasLinks

™

.

❏ 9. Locate the .074" x 1" [1.8 x 25.4mm] threaded

wire. Screw it into one end of the remaining inner

plastic pushrod. Slide a silicone retainer onto the end

of a nylon clevis. Screw the nylon clevis onto the

threaded wire.

❏ 10. Slide the inner plastic pushrod into the throttle

pushrod tube. Insert it from the firewall back into the

fuselage. Attach the clevis to the throttle arm and fully

close the throttle. Position the throttle servo so that it

would be in the position that will fully close the throttle.

❏ 11. Cut the inner plastic pushrod tube 2" from the

throttle servo. Remove the throttle pushrod from the

plastic pushrod tube.

❏ 12. Screw the .074" x 4" [1.8 x 102mm] wire

(threaded one end) onto the end of the plastic inner

pushrod tube. Reinsert the pushrod into the throttle

pushrod tube.

❏ 13. With the throttle pushrod connected to the

throttle arm and the servo positioned to close the

throttle, mark the pushrod wire where it aligns with

the servo arm. Remove the pushrods, then trim them

about 1" past the mark.

❏ 14. Enlarge one outside hole in the throttle servo

arm with a 5/64" bit. Make a 90 degree bend in the

pushrod at the point that you marked. Cut off the

excess wire, leaving about 3/8" after the bend.

Remove the clevis, then insert the pushrods all the

way into the tubes from the servo end. Reattach the

clevis and silicone retainer. Insert the upturned wire

through the servo horn and secure it in position with

nylon FasLinks.

❏ 15. Repeat step 14 for the steering pushrod.

26