Top Flite TOPA0210 User Manual

Page 10

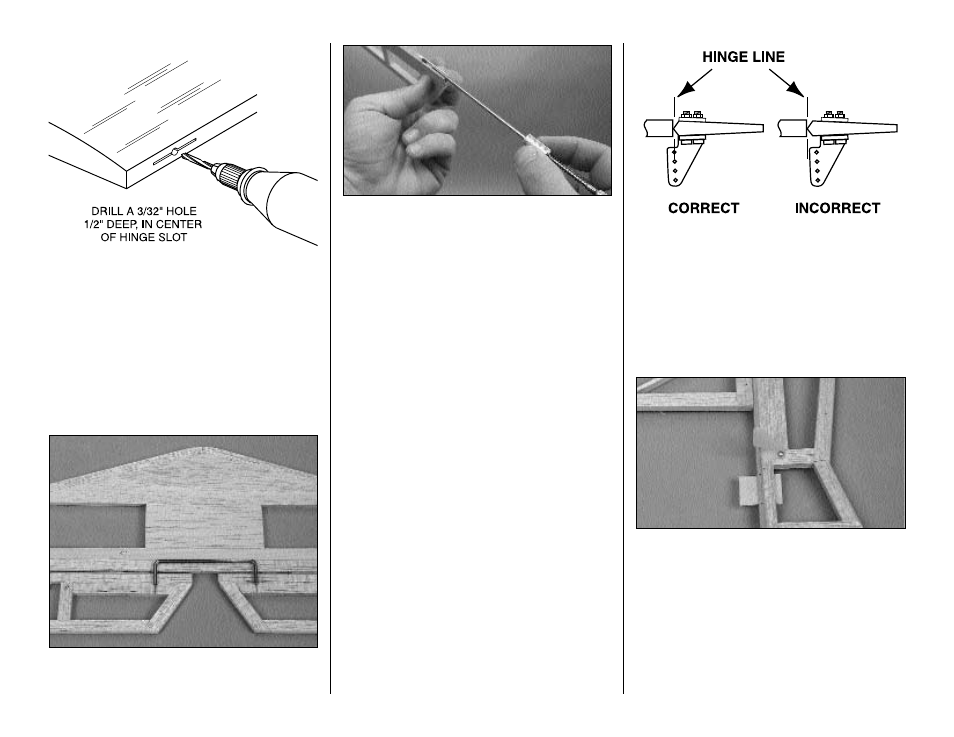

❏ 5. Drill a 3/32" [2.40mm] hole, 1/2" [13mm] deep in

the center of the hinge slots. Use a rotary tool with a

3/32" [2.40 mm] drill bit or a carbide cutter for the

best results. Re-insert your knife blade to clean out

the slot after you drill the hole.

❏ 6. Test fit the elevator halves to the stab with

the hinges.

❏ 7. Position the elevator joiner wire on the trailing

edge of the stab and center it between the elevators.

Mark the LE of both elevators where the joiner will enter.

❏ 8. Cut a slot in the leading edge of both elevator

halves to accommodate the joiner wire. This can be

done easily with the Great Planes “Groove

Tube”™ as shown in the photograph. Hint: If you do

not have a Groove Tube, use a 5/32" [4mm] brass

tube sharpened at one end to cut the slot.

❏ 9. Accurately drill holes in the elevators for the 1/8"

joiner wire. Begin by drilling a 1/16" [1.6mm] pilot

hole. Then drill the final hole to a depth of 7/8"

[22.2mm] with a 9/64" [3.6mm] drill bit. (The hole is

drilled slightly oversize to allow for positioning and to

create a hard epoxy “sleeve” around the wire).

❏ 10. Roughen the joiner wire with coarse sandpaper,

then clean the wire thoroughly with alcohol to remove

any oily residue.

❏ 11. Test fit the joiner wire into the elevators. Then,

glue it in using epoxy. When gluing, lay the elevators

on a flat surface with the LE along a straightedge to

insure perfect alignment. Cover the top of the joined

elevators with a sheet of wax paper. Then, lay a flat,

heavy object on top. A telephone book works well.

This will insure a true flat elevator assembly when

the epoxy cures.

Install the control horns

❏ 1. Place a large control horn at the location

indicated on the elevator plan and rudder plan. Use

a ballpoint pen to mark the location where the holes

need to be drilled.

❏ 2. Check for correct alignment. Drill two 3/32"

[2.4mm] holes for the control horn mounting bolts

through the rudder .

❏ ❏ 3. Repeat step 2 for the right half of the elevator.

❏ 4. Apply a small drop of thin CA in the holes to

harden the wood. Redrill the holes after the CA

has hardened.

❏ 5. Attach the control horn to the left side of the

rudder with two 2-56 x 1/2" [12.7mm] machine

screws.

❏ 6. Attach the control horn to the bottom right side

of the elevator with two 2-56 x 1/2" [12.7mm]

machine screws.

There, that went pretty quick. If your workbench is a

mess, clean it off and get ready to move on to the wing!

10