Tii 95S Series User Manual

Page 2

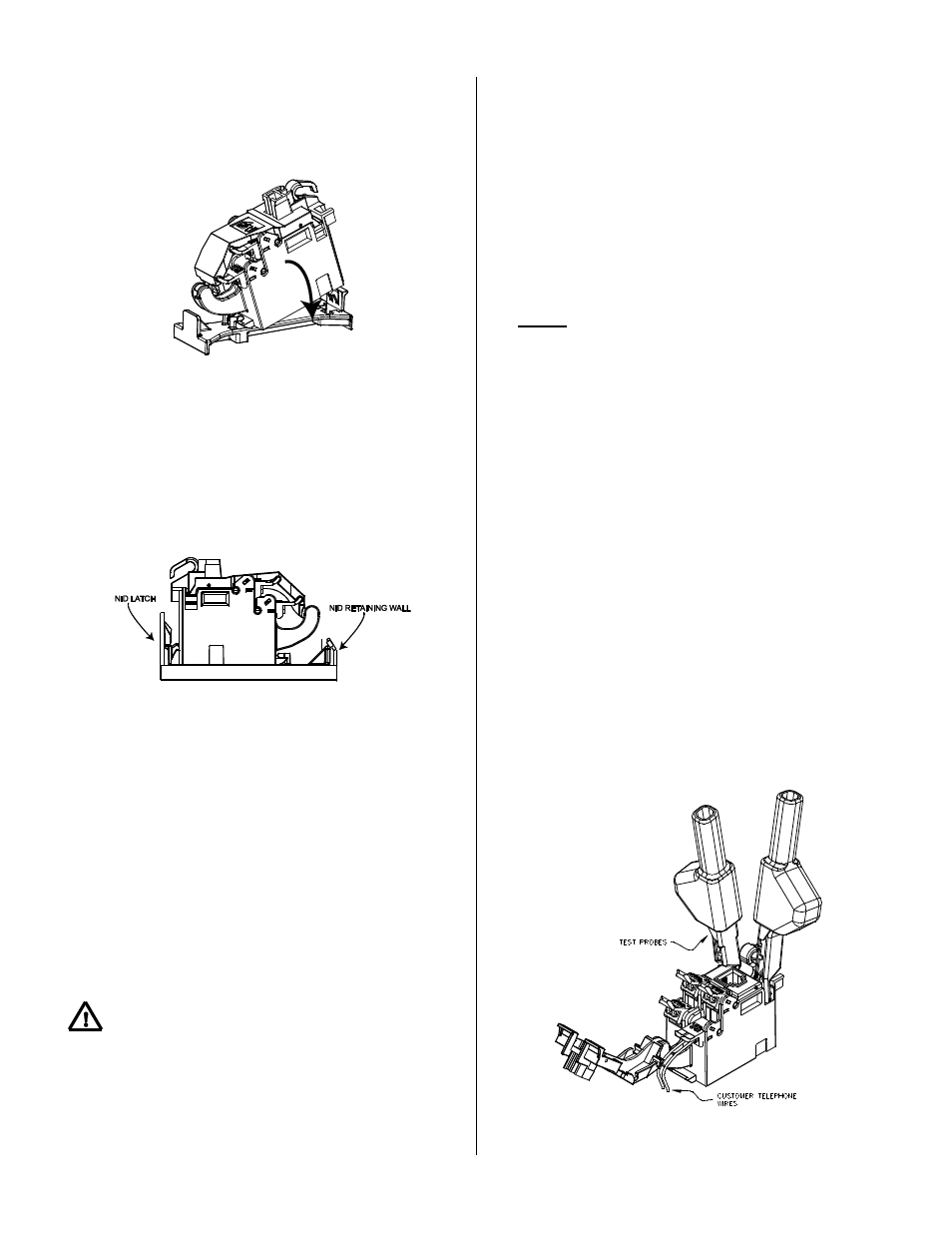

Installing Customer Bridge Module into Alternate

NID

1. Snap the adapter onto the CBM module (See

Figure 4).

Figure 4

2. With the CBM and adapter turned so the wires

are to the left, put the right side of the adapter

under the NID retaining wall.

3. Using your thumb, pull the NID latch to the left.

Press the CBM down and release the NID

latch to secure the CBM into position, (See

Figure 5).

Figure 5

Wiring

CBM Wiring

1. Four independent telephone pairs can be

connected to a single CBM module. The

customer has the option of putting a #10

Master lock in the customer lock hasp (See

Figure 1).

2. When installing the first pair of customer

telephone wires, always begin with the bottom

terminating rockers (See Figure 1).

3. Do not strip wire insulation from wires to be

terminated to CBM.

CAUTION: TO REDUCE THE RISK OF

PERSONAL INJURY, INSERT A RJ-11

PLUG INTO THE CUSTOMER TEST JACK

PRIOR TO MAKING ANY WIRING

CONNECTIONS.

4. Dress terminating wires (to protector) over NID

divider (See Figure 2).

5. Insert and terminate TIP (GRN) & RING (RED)

wires into sealed IDC station protector (see

protector installation note for further details).

6. Open customer security cover on CBM

module.

7. Lift all CBM rockers to the open position as

shown (See Figure 1).

8. Dress wires around customer security cover.

9. Hold the customer telephone wires between

thumb and index finger (approx. 1/8”

separation between wires).

NOTE: Wires should be aligned to the corresponding

holes. Green wire to the “T” (GRN) labeled wire guide

and the Red wire to the

“R” (RED) labeled wire guide.

10. Insert wires into wire guides at the same time

until they bottom out.

11. While holding wires in wire guides, terminate

rocker with thumb (lower rocker all the way).

12. Terminate additional pairs to rockers as

required.

13. Assure all rockers are in the down position

and close customer security cover.

Central Office Signal Testing

1. Open customer security cover.

2. Insert RJ-11 plug into customer test jack to

isolate telco and customer wiring.

3. Using an ohmmeter, insert test clips into test

ports as shown (See Figure 6).

4.

If continuity is measured a “short” may exist in

the customer premise.

5. Wires are ok if meter shows a reading.

Figure 6