Tii FDT1 Series User Manual

Page 2

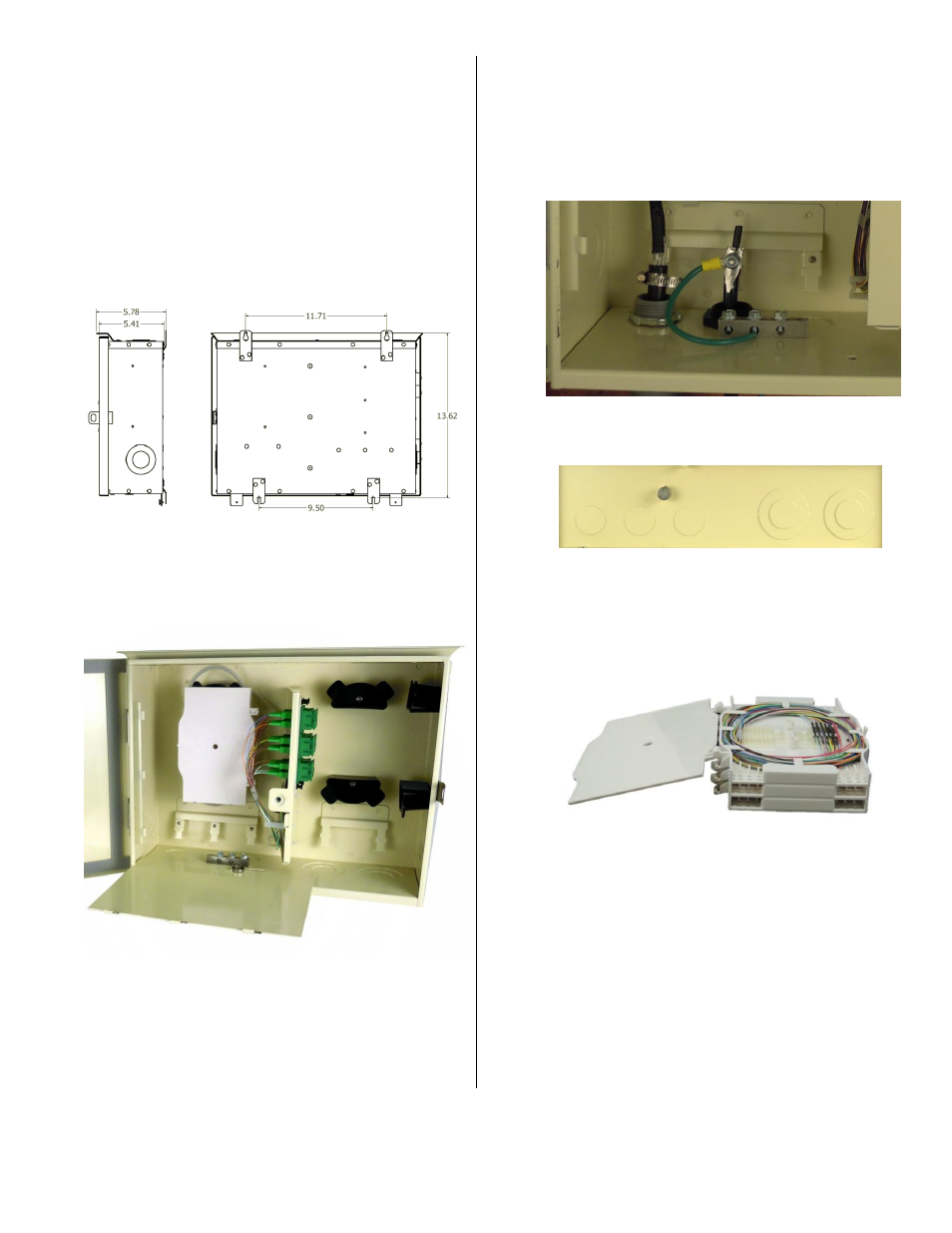

3. Knock out required cable entry conduit ports.

Top

– 2 ea combination 1” / 2”

Side

– 1 ea combination 1” / 2 “

Bottom

– 2 ea combination 1” / 2”

3 ea 1”

4. Trim and install conduit fittings or NPT

compression couplings as needed.

5. Mark and install appropriate wall hanging

hardware and secure unit.

Figure 3

6. The inner door can be used as a work surface

in remote or confined space installations. Lift

the inner door from hinges and use 216 tool to

secure 3/8” bolt to bottom of enclosure.

Figure 4

7. Cut excess feeder cable to length leaving a

minimum of 3 ft. of slack from point of entering

splice bay. Location to perform fusion splicing

will dictate exact length necessary of slack.

Remove protective jacketing material to

expose fiber cable subunits and secure to

cable entry point. Ground and bond armored

or tonable cable using provided ground bar.

Figure 5

8. Ground the FDT enclosure to a suitable earth

ground using the external ground stud.

Figure 6

9. Splice feeder fiber to pigtails using the FST

modular splice tray. The trays are stackable

and have 3 attaching points to secure one tray

to the other. Each tray can splice up to 24

single fusions or 6 mass fusions.

Figure 7

10. Store feeder fibers and pigtail slack in

provided slack management rings.

11. Customer drops are routed from the cable

entry ports to the patch panel and slack is

stored in the provided slack management

rings.