Encoding the lh 1200, Working width, Forward speed calibration (wheel circumference) – TeeJet LH 1200 User Manual

Page 15

LH 1200 O

PERATORS

& F

ITTING MANUAL

E

NCODING THE

LH 1200

LH A

GRO

15

ENCODING THE LH 1200

WORKING WIDTH

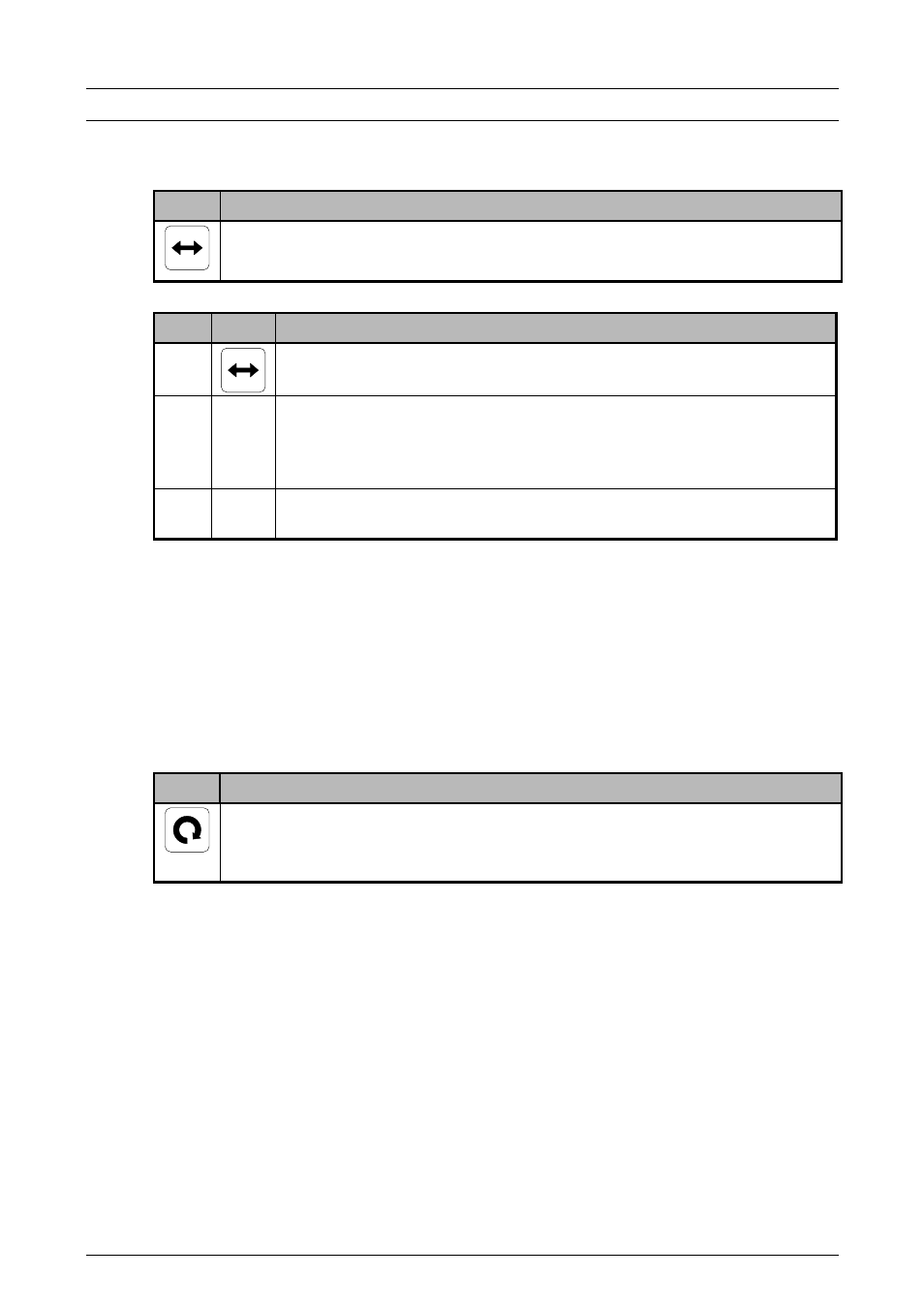

Key

Function

Working width:

The working width of the implement being used is encoded here.

Step Key Procedure

1

Press the working width key.

2

Encode the working width in centimetres using the numerical

keys. Ensure that overlaps are accounted for. If the working width

is unknown, then drive 5 bouts and measure the distance between

the first and the last, then divide the distance by 5.

3

The encoded value is stored automatically until another working

width is encoded; press any other key to leave this encodement.

FORWARD SPEED CALIBRATION (WHEEL CIRCUMFERENCE)

Key

Function

Wheel circumference:

The distance in centimetres that is driven per pulse from the speed

sensor is encoded here.

Depending on which vehicle is used the speed signal can come from a sensor built

into the gearbox, from a sensor fitted by the prop. Shaft (4-wheel drive) or from a

sensor fitted by one of the wheels.

NOTE!

It is recommended to fit as many magnets on the wheel as necessary to

ensure that the encoded wheel circumference does not exceed 100 cm.

Remember that it is important that the distance between the magnets is the

same. Otherwise, the displayed speed will fluctuate.