Slant/Fin HWT-120 User Manual

Page 5

5

INDIRECT FIRED WATER TANK

IV INSTALLATION/PIPING

The Location of the heater.

Locate the heater so that there is easy access to the control,

piping, valves, drain and heater for future servicing and main-

tenance. The heater is to be kept in an area where it is not

exposed to freezing temperatures.

Also, the heater must be located in an area where a leak

(eg. from the piping or fittings, from any temperature and

relief valve discharge, or from the tank itself), will not cause

personal harm or damage the surrounding area. The tank

should be installed in an area with a floor drain or in a pan

suitable for water heaters.

Slant/Fin will not be held liable for any damages caused by

water leakage.

The floor or area where the tank is installed must be

capable of supporting the tank when filled with water.

(Refer to Table at right.)

Read the Installation and Operating Instructions manual

thoroughly. Follow recommended piping and wiring diagrams.

Upon completing installation, fill the tank with water. While

filling it leave a hot water faucet open until a steady stream of

water is flowing. Then, shut the faucet and check for any leaks

thoughout the entire system.

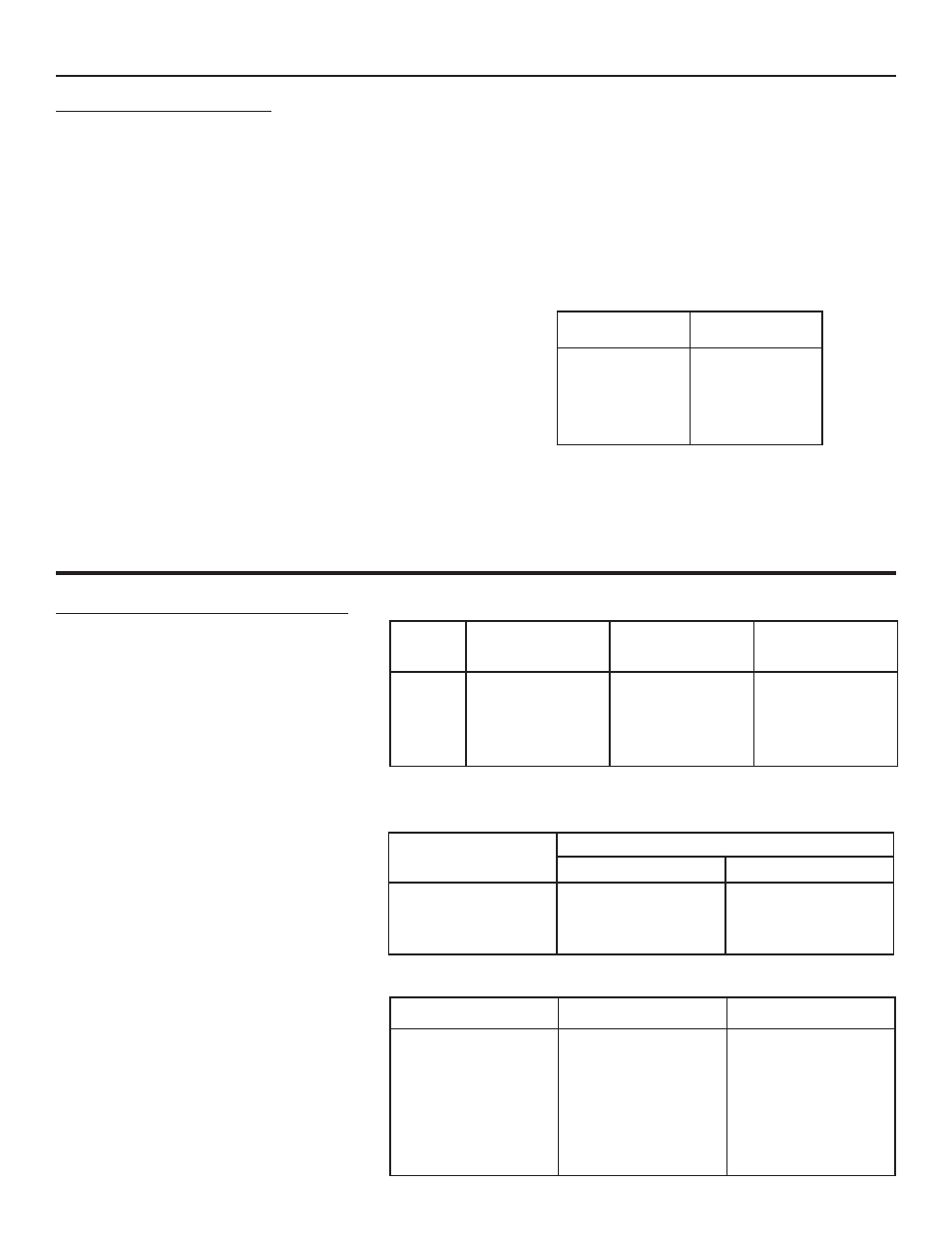

Model

Weight (lbs.)

HWT-40

HWT-60

HWT-80

HWT-120

449

576

737

1324

TANK WEIGHT WHEN FILLED

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

Controls on this appliance could ignite vapors causing an explosion

PIPING

1. General

a. All plumbing must be in accordance with

the requirements of the authority having

jurisdiction.

b. Use both thread tape and pipe dope on all

mechanical connections.

c. Zone valve (if used) and circulator must be

sized to provide minimum flow rate specified

in the table to the right, Flow Specifications.

Use 1 inch nominal copper tubing between

boiler and heat exchanger. See the tables on

Friction Loss. Point of emphasis: using a

zone valve without a full bore may cause

high pressure drop which will adversely

affect performance. Use extreme care when

selecting zone valve.

d. All piping must be adequately supported.

e. Allow for thermal expansion.

f. Dielectric Unions (recommended)-used to

electrically isolate the tank from the connect-

ed domestic water piping. This helps to min-

imize the possiblity of corrosion

damage.

Model No.

Recommended

Flow Rate

Heat Exch.Pressure

Drop (Ft. Hd.)

Domestic Water

Connection Sizes

HWT-40

HWT-60

HWT-80

HWT-120

10 GPM

10 GPM

14 GPM

14 GPM

2.3

2.3

11

11

3/4"

3/4"

1"

1" MPT

Tubing Type

Flow Rate (gpm)

10 gpm

15 gpm

Type K

Type L

Type M

3.1 psi

2.7 psi

2.3 psi

6.5 psi

5.7 psi

4.7 psi

Fitting

Wrought

Cast

90º Elbow

45º Elbow

Tee, Run

Tee, Branch

90º Bend

180º Bend

Gate Valve

1

1

1/2

3

2

2

-

4

2

1/2

5

-

-

1

Flow Specifications

Friction Loss 100 Feet of Tubing (psi)

Friction Loss Allowance for Copper Fittings

(feet of straight tubing

)

Notes: All fittings are female NPT thread connections