Warning, Troubleshooting, Wiring diagrams – SeaLand M Series Vacuum Pump User Manual

Page 7

7

TRoUblEShooTIng

WARNING

Before attempting to open or service the pump:

1. If possible, flush pump with clean water and disinfectant.

2. allow motor to cool if overheated.

3. disconnect power supply to pump before servicing unit.

Follow proper lock-out/tag-out procedures.

Problem

Possible Cause

Service Instruction

1. pump fails to prime.

a. air leak(s) in suction (inlet) line.

b. suction (inlet) line collapsed.

c. suction (inlet) or discharge (outlet) check

valves clogged or worn out.

d. torn or broken diaphragm.

e. suction line clogged.

f. diaphragm or flange bolts loose.

a. Correct leak.

b. Replace suction line.

c. Clean or replace valves (4 required).

d. Replace diaphragm.

e. Clean suction line.

f. Tighten bolts.

2. pump stops or has reduced flow.

a. air in suction line.

b. suction line collapsed.

c. torn or broken diaphragm.

d. Clogged suction or discharge line.

e. suction lift or discharge lift (head) too high.

f. suction or discharge valves in pump clogged

or defective.

a. Correct leak.

b. replace suction line.

c. replace diaphragm.

d. Clean suction or discharge line.

e. Check installation and correct as required.

f. Clean or replace valves (4 required).

3.

Excessive current draw requires too

much power

.

a. Liquid solution too thick.

b. Discharge valves in pump clogged.

c. Excessive suction or discharge lifts

(head).

a. Dilute if possible.

b. Clean or replace valves (2 required).

c. Check installation and correct as

required

4. excessive noise.

a. pump, gear reducer or motor loose.

b. Gear reducer oil is low.

a. tighten bolts.

b. Check oil level.

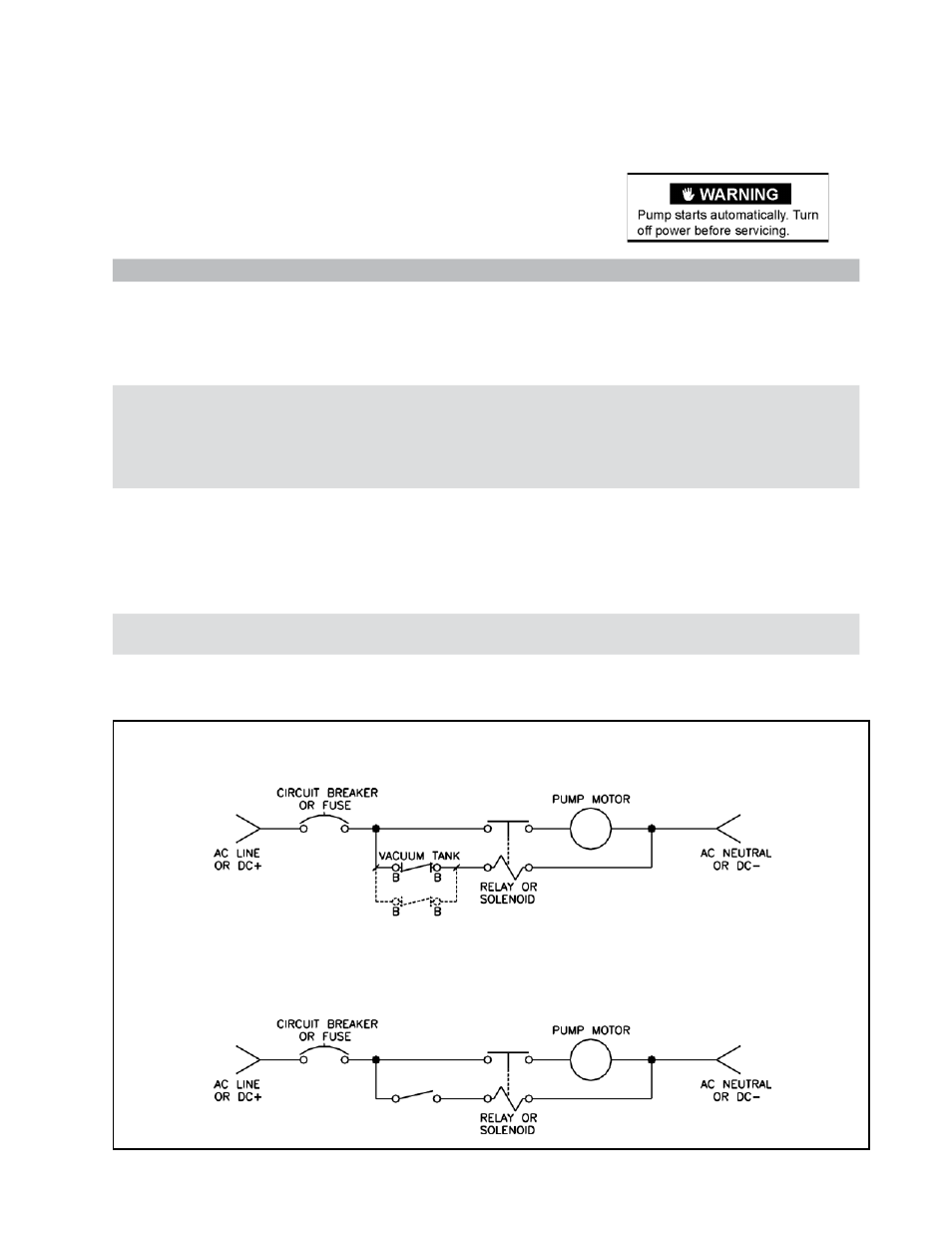

WIRIng dIAgRAMS

M-Series Vacuum Pump Wiring Schematic

(VacuFlush System)

Note: Vacuum tank pressure switches are wired in parallel for multiple toilet installations. Wire to B connections only.