Warning – Reznor S5BP Unit Installation Manual User Manual

Page 5

5

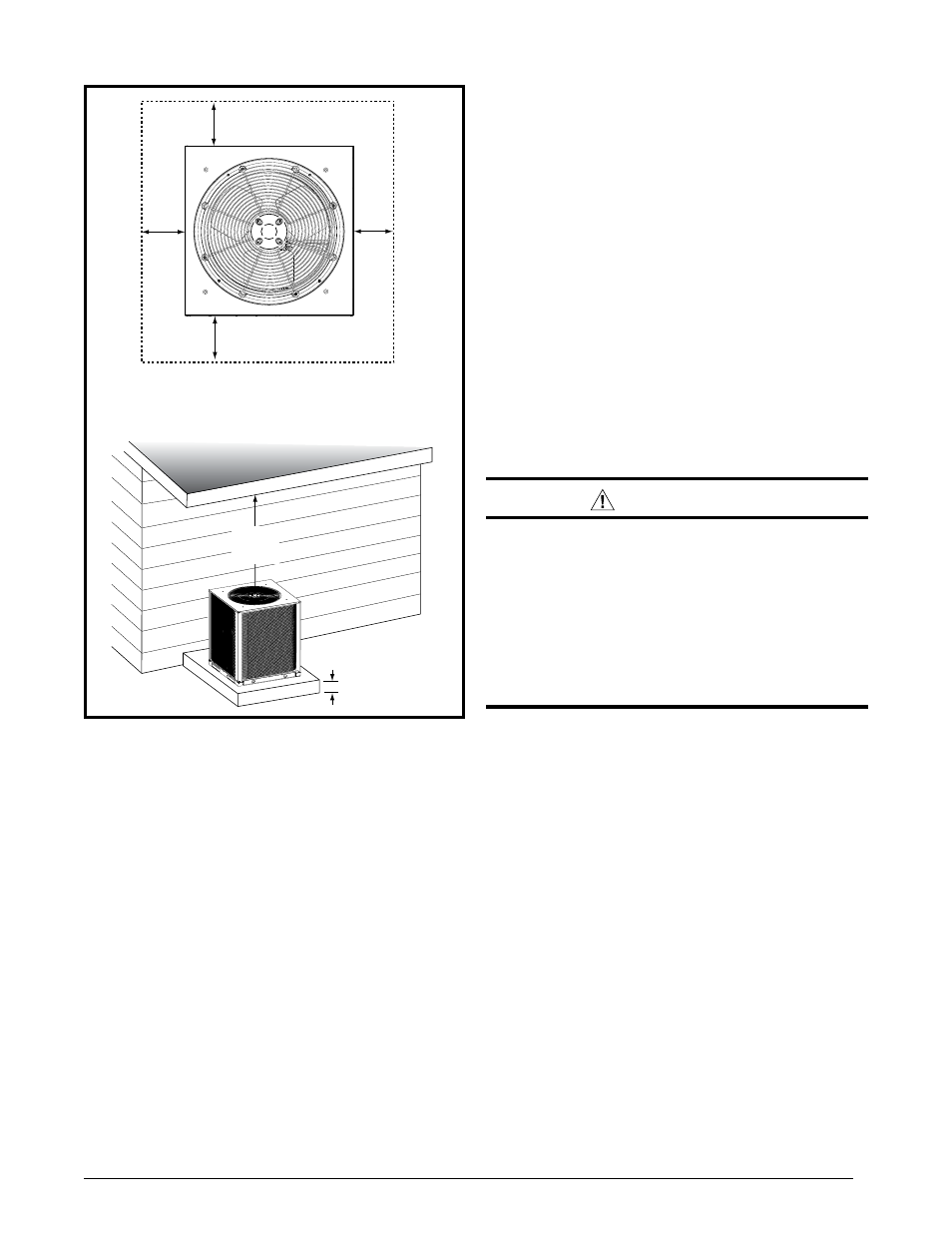

Figure 1. Minimum Clearance Requirements

18"

18"

18"

18"

DO NOT OBSTRUCT

TOP OF UNIT

2”

NOTE: Units require full perimeter clearances. Installer must maintain

18” between two units or single unit and structure.

72”

• When connecting refrigerant linesets together, it is

recommended that dry nitrogen be flowing through

the joints during brazing. This will prevent internal

oxidation and scaling from occurring.

• Refrigerant tubing should be routed in a manner

that minimizes the length of tubing and the number

of bends in the tubing.

• Refrigerant tubing should be supported in a manner

that the tubing will not vibrate or abrade during

system operation.

• Tubing should be kept clean of foreign debris during

installation.

• Every effort should be made by the installer to

ensure that the field installed refrigerant containing

components of the system have been installed

in accordance with these instructions and sound

installation practices to insure reliable system

operation and longevity.

• The maximum recommended interconnecting

refrigerant line lengths are listed in Table 4 (page

13) and the vertical elevation difference between

the indoor and outdoor sections should not exceed

20 feet.

• If precise forming of refrigerant lines is required, a

copper tubing bender is recommended. Avoid sharp

bends and contact of the refrigerant lines with metal

surfaces.

• A filter dryer is provided with the unit and must

be installed in the liquid line of the system. If the

installation replaces a system with a filter dryer

already present in the liquid line, the filter dryer must

be replaced with the one supplied with the unit. The

filter dryer must be installed in strict accordance

with the manufacturer’s installation instructions.

• Optional equipment such as liquid line solenoid

valves, low ambient, etc., should be installed in

strict accordance with the manufacturer’s installation

instructions.

ElECtRICAl WIRInG

WARnInG:

to avoid risk of electrical shock, personal

injury, or death, disconnect all electrical power

to the unit before performing any maintenance

or service. the unit may have more than one

electrical supply.

label all wires prior to disconnection when

servicing the unit. Wiring errors can cause

improper and dangerous operation

• All electrical connections must be in compliance with

all applicable local codes and ordinances, and with

the current revision of the National Electric Code

(ANSI/NFPA 70).

• For Canadian installations the electrical connections

and grounding shall comply with the current

Canadian Electrical Code (CSA C22.1 and/or local

codes).

Pre-Electrical Checklist

√ Verify that the voltage, frequency, and phase of the

supply source match the specifications on the unit

rating plate. Refer to Table 4 (page 11).

√ Verify that the service provided by the utility is

sufficient to handle the additional load imposed

by this equipment. Refer to the unit wiring label for

proper high and low voltage wiring.

√ Verify factory wiring is in accordance with the unit

wiring diagram (Figure 2, page 12). Inspect for loose

connections.

√ Phase balance on 3 phase units must always be

checked. See Unbalanced 3-Phase Supply Voltage

section (page 7).