Carrier 19XL User Manual

Page 21

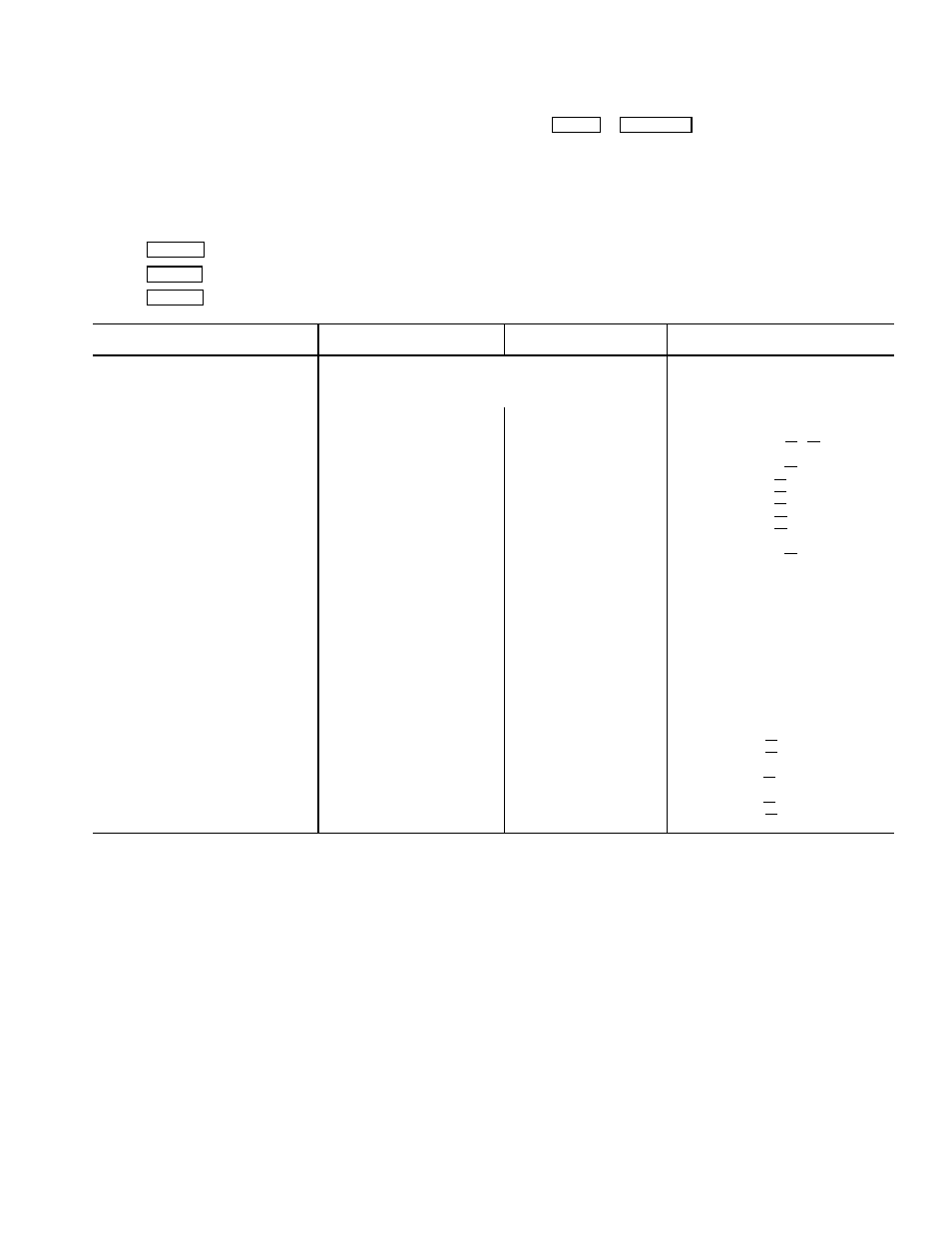

Table 2 — LID Screens

NOTES:

1. Only 12 lines of information appear on the LID screen at any given time. Press

NEXT

or PREVIOUS to highlight a point or to view points

below or above the current screen.

2. The LID may be configured in English or SI units, as required, through the LID configuration screen.

3. Data appearing in the Reference Point Names column is used for CCN operations only.

4. All options associated with ICE BUILD, Lead/Lag, CCN Occupancy Configuration, and Soft Stopping are only available on PSIO Software

Version 9 and higher.

EXAMPLE 1 — STATUS01 DISPLAY SCREEN

To access this display from the LID default screen:

1. Press

MENU

.

2. Press STATUS (STATUS01 will be highlighted).

3. Press SELECT .

DESCRIPTION

RANGE

UNITS

REFERENCE POINT NAME

(ALARM HISTORY)

Control Mode

Reset, Off, Local, CCN

MODE

Run Status

Timeout, Recycle, Startup,

Ramping, Running, Demand, Override,

Shutdown, Abnormal, Pumpdown

STATUS

Occupied ?

No/Yes

OCC

Alarm State

Normal/Alarm

ALM

*Chiller Start/Stop

Stop/Start

CHIL

S

S

Base Demand Limit

40-100

%

DLM

*Active Demand Limit

40-100

%

DEM

LIM

Compressor Motor Load

0-999

%

CA

L

Current

0-999

%

CA

P

Amps

0-999

AMPS

CA

A

*Target Guide Vane Pos

0-100

%

GV

TRG

Actual Guide Vane Pos

0-100

%

GV

ACT

Water/Brine: Setpoint

10-120 (–12.2-48.9)

DEG F (DEG C)

SP

*

Control Point

10-120 (–12.2-48.9)

DEG F (DEG C)

LCW

STPT

Entering Chilled Water

–40-245 (–40-118)

DEG F (DEG C)

ECW

Leaving Chilled Water

–40-245 (–40-118)

DEG F (DEG C)

LCW

Entering Condenser Water

–40-245 (–40-118)

DEG F (DEG C)

ECDW

Leaving Condenser Water

–40-245 (–40-118)

DEG F (DEG C)

LCDW

Evaporator Refrig Temp

–40-245 (–40-118)

DEG F (DEG C)

ERT

Evaporator Pressure

–6.7-420 (–46-2896)

PSI (kPa)

ERP

Condenser Refrig Temp

–40-245 (–40-118)

DEG F (DEG C)

CRT

Condenser Pressure

–6.7-420 (–46-2896)

PSI (kPa)

CRP

Discharge Temperature

–40-245 (–40-118)

DEG F (DEG C)

CMPD

Bearing Temperature

–40-245 (–40-118)

DEG F (DEG C)

MTRB

Motor Winding Temp

–40-245 (–40-118)

DEG F (DEG C)

MTRW

Oil Sump Temperature

–40-245 (–40-118)

DEG F (DEG C)

OILT

Oil Pressure Transducer

–6.7-420 (–46-2896)

PSI (kPa)

OILP

Oil Pressure

–6.7-420 (–46-2896)

PSID (kPad)

OILPD

Line Voltage:

Percent

0-999

%

V

P

Actual

0-9999

VOLTS

V

A

*Remote Contacts Input

Off/On

REMCON

Total Compressor Starts

0-65535

c

starts

Starts in 12 Hours

0-8

STARTS

Compressor Ontime

0-500000.0

HOURS

c

hrs

*Service Ontime

0-32767

HOURS

S

HRS

*Compressor Motor kW

0-9999

kW

CKW

NOTE: All values are variables available for read operation to a CCN. Descriptions shown with (*) support write operations for BEST programming

language, data transfer, and overriding.

21