Novak SLYDR Drift ESC (55-1712-1) User Manual

Slydr drift esc instruction manual, Specifications, Precautions replacement items

#55-1712-1

6-2008

SPECIFICATIONS

Input Voltage ...........................4-6 cells

(1.2 volts DC/cell) or 2S Li-Po

ESC Footprint ...........................................1.16”x1.49”

[29.5x37.8mm]

ESC Weight

(w/o wires)

.................................1.36 ounce

[38.5 grams]

B.E.C. Voltage .............................................................6.0 volts DC

B.E.C. Current ................................................................. 3.0 amps

Power Wire

(Battery/Motor)

......................... 14G Super-Flex Silicone

On-Resistance ........................................0.00040Ω

@25°C trans.temp.

Rated Current

(

per phase

)

...................540A

[Fwd & Rev.]

@25°C trans.temp.

Motor Limit ...................................

5.5-turn Novak 540-size brushless motor

RACING POWER TRANS-CAP MODULE [#5679]

The factory-installed Racing Power Trans-Cap Module MUST BE USED for

proper operation. For replacement, Novak item #5679 must be used.

Note: We recommend using Novak Power Trans-Caps only. We’ve done extensive testing & research to

find components with the very best quality factors––other capacitors will not provide equal protection.

SUPER-FLEX SILICONE 14G WIRE [#5514/#5508]

#5514 Includes 3 feet each of Red, Black, and Blue Wire

#5508 Includes 2 each of 9” Red, Black, Blue, Yellow, & Orange Wire

INPUT SIGNAL HARNESSES [#5315/#5320]

Available in either short(#5315, 4.5”) or long (#5320, 9.0”) lengths.

MOTOR BEARING & END BELL SET [#5919]

After extensive use, the ball bearings in the motor may need replacement.

Includes a front end bell with bearing factory-installed & a rear bearing.

MOTOR REPLACEMENT SINTERED ROTOR-13MM [#5909]

After extensive use, the rotor may need replacement due to loss of magnetic

strength

(normal after extended use)

. Novak’s Drift BL motors use a 13mm rotor.

HIGH-VOLUME COOLING FANS [#5648/#5652]

The 30x30x6 Cooling Fan should be used for increased ESC efficiency. Fans

include a plug for easy plug-in to SLYDR. Item #5652 is a 2-pack.

REMOTE POWER PROGRAMMING SWITCH [#5602]

Combination Power ON/OFF Switch & One-Touch Programming Button

WATER & ELECTRONICS DON’T MIX!

Never allow water, moisture, or other foreign materials to get inside ESC,

motor, or on the PC Boards. Water damage will void the warranty!

DO NOT FREE REV OR OPERATE WITHOUT LOAD

This includes running the motor without a pinion or holding the car

in the air and running the motor at or close to full power.

Free revving will void the warranty!

NO SCHOTTKY DIODE!

Schottky diodes must NOT be used with brushless ESCs. Using

a Schottky diode will damage the ESC & void the warranty.

DISCONNECT BATTERIES WHEN NOT IN USE

Always disconnect the battery pack from the speed control when

not in use to avoid short circuits and possible fire hazard.

4 TO 6 CELLS ONLY, OR 2S LI-PO

Never use fewer than 4 or more than 6 cells (4.8-7.2VDC, 1.2VDC/cell) in

the vehicle’s main battery pack, or more than 2-Li-Po cells.

For use with

2S Li-Po pack, the Li-Po Cut-Off must be enabled (refer to page 4).

NOVAK BRUSHLESS MOTORS ONLY

The SLYDR Drift ESC is specially designed for drifting. Use only Novak

Drift-Series Brushless Motors for ideal drifting performance.

NO REVERSE VOLTAGE!

Reverse battery polarity can damage ESC & void warranty. Disconnect

battery immediately if a reverse connection occurs.

POWER CAPACITOR REQUIRED

An external Power Capacitor Module is installed and MUST be used

with your ESC. Failure to use Power Capacitor will result in higher

ESC operating temperatures & possible thermal shut-down.

TRANSMITTER ON FIRST

Always turn on the power of the transmitter first so that you will have

control of the vehicle when you turn it on.

INSULATE WIRES

Always insulate exposed wiring with heat shrink tubing or electrical

tape to prevent short circuits, which can damage ESC.

NO CA GLUE

Exposure to CA glue or its fumes can cause damage to internal

components of the speed control and result in premature failure.

PrECAuTIONS

rEPLACEMENT ITEMS

P1

PrOduCT wArrANTy

The SLYDR Drift ESC is guaranteed to be free from defects in materials or workmanship for a period of 120

days from the original date of purchase (verified by dated, itemized sales receipt). Warranty does not cover

incorrect installation, components worn by use, damage to case or exposed circuit boards, damage from using

fewer than 4 or more than 6 cells (1.2 volts DC/cell) or more than 2S Li-Poly cells input voltage, cross-connection

of battery/motor power wires, damage from cross phase connection, overheating solder tabs, reverse voltage

application, damage resulting from thermal overload or short-circuiting motor, damage from incorrect installa-

tion of FET servo or receiver battery pack, not using or incorrect installation of a Power Capacitor on the ESC

or from using a damaged Power Capacitor, using a Schottky diode, damage from free revving motor, using

non-Novak Power Capacitor or motor, splices to input, ON/OFF switch, or sensor harnesses, damage from

excessive force when using the One-Touch/SET button or from disassembling case, tampering with internal

electronics, allowing water, moisture, or any other foreign material to enter ESC or get onto the PC board,

incorrect installation/wiring of input plug plastic, allowing exposed wiring or solder tabs to short-circuit, or any

damage caused by a crash, flooding or natural disaster.

Because Novak Electronics, Inc. has no control over the connection & use of the speed control or other related

electronics, no liability may be assumed nor will be accepted for any damage resulting from the use of this

product. Every Novak speed control & motor is thoroughly tested & cycled before leaving our facility and is,

therefore, considered operational. By the act of connecting/operating speed control, user accepts all resulting

liability. In no case shall our liability exceed the product’s original cost. We reserve the right to modify warranty

provisions without notice.

©2008 Novak Electronics, Inc. • All Rights Reserved • No part of these instructions may be reproduced without

the written permission of Novak Electronics, Inc. • SLYDR Drift ESC & One-Touch Set-Up are trademarks of

Novak Electronics, Inc. • All Novak speed controls & motors are designed & assembled in Irvine, California.

SLYDR DRift eSc inStRuction manuaL

P4

@NEUTRAL

RED LED on solid

MIN. BRAKE

BLUE

press & hold

press & hold

press & hold

press & hold

DRAG BRAKE

BLUE & AMBER

DEAD BAND

BLUE & GREEN

MIN. DRIVE

AMBER

press & hold

THROTTLE CURVE

GREEN

LEDs roll off

Exit Programming

@NEUTRAL

RED LED on solid

press & hold

BRAKE FREQUENCY

RED

press & hold

REVERSE

RED / GREEN / AMBER

press & hold

MOTOR ROTATION

RED / GREEN / BLUE

press & hold

LI-PO CUT-OFF

RED & AMBER

press & hold

continue holding ESC

’s SET

button to skip steps here

1. IF TRANSMITTER IS OFF,

DISCONNECT ESC FROM

RECEIVER

Remove input signal harness

from the receiver to avoid radio

interference.

2. CONNECT ESC TO A

CHARGED BATTERY PACK

3. SLIDE ESC’s ON/OFF

SWITCH TO ‘ON’ POSITION

4. WITH ESC AT NEUTRAL

PRESS & HOLD ESC’S SET

BUTTON

Release ESC’s SET button once

LED is at desired setting.

To skip a parameter, continue to

press and hold ESC’s SET button

to the desired parameter.

5. SELECT PARAMETER VALUE

LED flashes to indicate active

setting (refer to tables at right).

Quick press & release SET

button to select desired setting.

6. PRESS & HOLD SET BUTTON

TO STORE SELECTION

When SET button is pressed and

held for about 1 second, the new

selection is stored in ESC’s

memory—The 4 status LEDs will

scroll across to indicate ESC is

exiting programming and ESC

returns to neutral.

Note: there is no time

constraint during selection

process of custom parameters.

Parameter

Default

Custom

Minimum Brake

12%

Drag Brake

12%

Dead Band

5%

Minimum Drive

2%

Throttle Curve

Expo-1

Brake Freq.

3 KHz

Reverse

OFF

Motor Rotation

CCW q

Li-Po Cut-Off

OFF

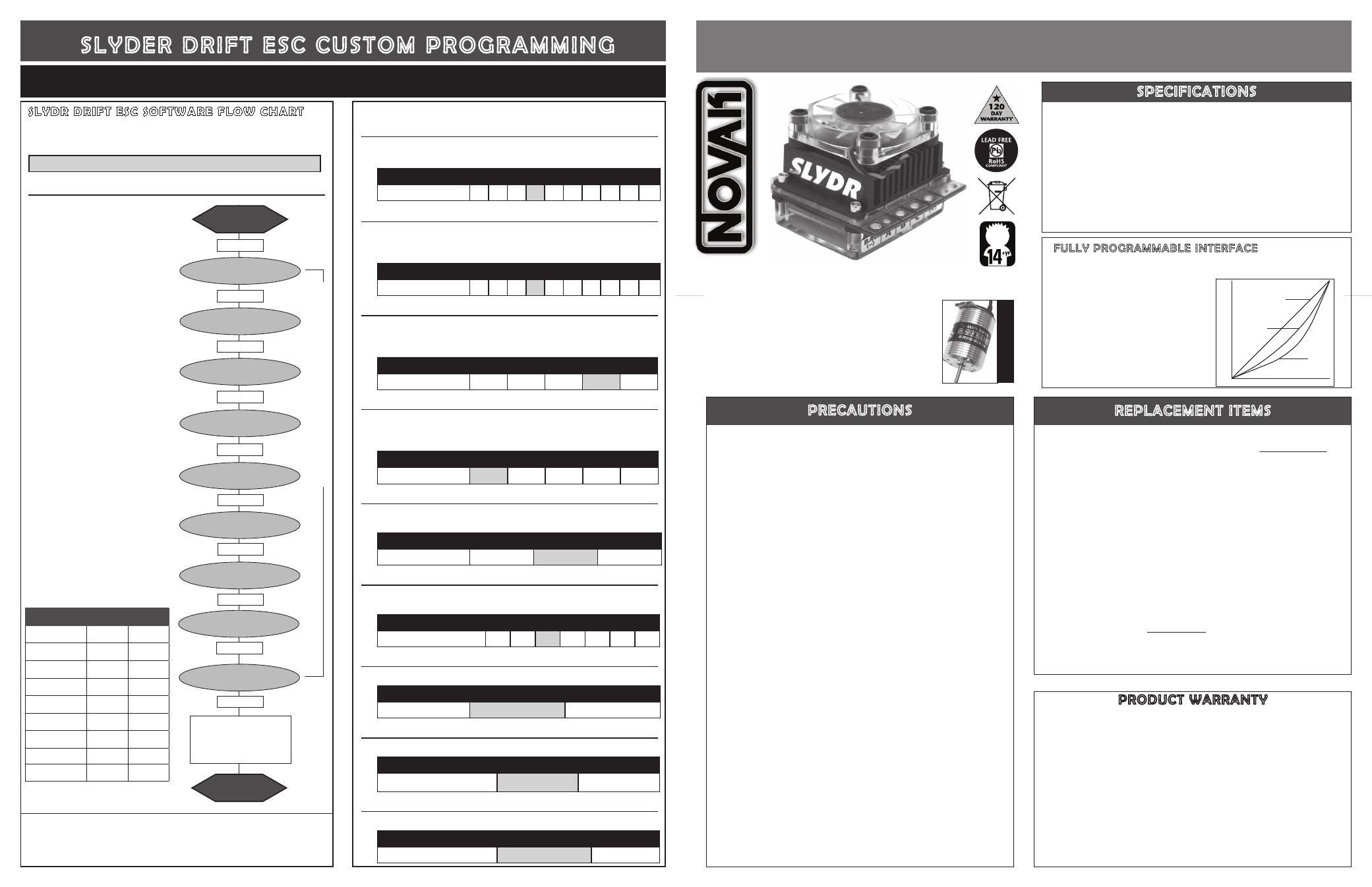

SLYDR DRIFT ESC SOFTWARE FLOW CHART

The SLYDR Drift ESC features nine parameters

that can be

adjusted. Refer to below flowchart and settings at right.

DEFAULT SETTINGS ARE IN BOLD IN TABLES

TO CHANGE PARAMETER SETTINGS:

Transmitter can be either ON or OFF:

ReStoRing factoRY DefauLtS:

Every time you perform the One-Touch Set-Up, the ESC is

defaulted to the factory default parameter settings.

THROTTLE PARAMETER SETTINGS

(Defaults in Bold)

1. minimum BRaKe SettingS (10)

BLUE LED

Amount of braking applied with first pulse of transmitter throttle information.

>>

Raising this setting starts the braking at a stronger/higher level

.

Setting

(# of flashes)

1 2 3 4 5 6 7 8 9 10

Minimum Brake (%):

3

6

9

12

15 18 20 30 40 50

2. DRag BRaKe SettingS (10) BLUE & AMBER LEDs

Amount of braking applied while transmitter is at neutral. ‘Coast’ brakes.

>>Raising this setting makes the motor slow down more, without

pushing the transmitter’s trigger into the brake/reverse direction.

Setting

(# of flashes)

1 2 3 4 5 6 7 8 9 10

Drag Brake (%):

3

6

9

12

15 18 20 30 40 50

3. DeaD BanD SettingS (5)

BLUE & GREEN LEDs

Space between Minimum Brake & Minimum Drive, with neutral in middle.

>>Raising this setting will increase the ‘free play’, or distance your

trigger must move before forward drive or braking will begin.

Setting

(# of flashes)

1

2

3

4

5

Dead Band (%):

2

3

4

5

6

4. minimum DRiVe SettingS (5)

AMBER LED

Amount of forward drive applied with first pulse of transmitter information.

>>Raising this setting makes the motor start at a stronger/higher

level so it takes off more aggressively from neutral.

Setting

(# of flashes)

1

2

3

4

5

Minimum Drive (%):

2

3

5

8

12

5. tHRottLe cuRVe SeLection (3)

GREEN LED

>>Changing this setting changes the throttle response and ease

of drivability.

Setting

(# of flashes)

1

2

3

Throttle Curve:

Linear

Expo-1

Expo-2

6. BRaKe fReQuencY (7)

RED LED

>>Raising this setting makes the brake response smoother and

more controllable.

Setting

(# of flashes)

1

2

3

4

5

6

7

Brake Frequency (KHz):

1

2

3

4

5

7.5

8

7. ReVeRSe (2)

RED, GREEN & AMBER LEDs

>>Changing this setting activates/deactivates reverse direction.

Setting

(# of flashes)

1

2

Reverse (On/Off):

Off (FWD/BRK)

On (FWD/BRK/REV)

8. motoR Rotation (2)

RED, GREEN & BLUE LEDs

>>Changing this setting changes direction of motor rotation.

Setting

(# of flashes)

1

2

Motor Rotation (CCW/CW):

CCW

q

CW

p

9. Li-Po cut-off (2)

RED & AMBER LEDs

>>Changing this setting enables/disables Li-Po cutoff (@6.25 volts).

Setting

(# of flashes)

1

2

Li-Po Cut-Off (On/Off):

OFF

ON

S L y d E r d r I F T E S C C u S T O M P r O g r A M M I N g

PLEASE NOTE: This page contains optional Advanced Programming items!

No further adjustments are required.

(But don’t worry, you can always reset factory defaults by performing the One-Touch programming again, so go ahead & experiment—that’s why the programming is in there, right?)

Recommended motor

for SL

YDR Drift ESC

Drift-Spec Brushless Motor

FuLLy PrOgrAMMABLE INTErFACE

The Novak’s SLYDR Drift Brushless ESC includes a Fully

Programmable Interface. Nine parameters can be adjusted. Refer to

Page 4 for Customization Instructions.

Minimum Brake

•

(10 settings)

Drag Brake

•

(10 settings)

Dead Band

•

(5 settings)

Minimum Drive

•

(5 settings)

Throttle Curve

•

(3 settings)

Brake Frequency

•

(7 settings)

Reverse

•

(2 settings)

Motor Rotation

•

(2 settings)

Li-Po Cut-off

•

(2 settings)

To benefit from all of the technical features

PLEASE READ ALL INSTRUCTIONS

THE ESC MADE FOR DRIFTERS

With some influence from the top drifters of the world,

Novak has developed the specially designed SLYDR

Drift ESC. This unequaled ESC contains new brake

adjustments and features to help fine tune brake response,

as well as all new Throttle Curve adjustments to further

customize the already-smooth throttle response.

Motor Output

Trigger Position

0

100%

100%

Linear

Expo-2

Expo-1

Throttle Curve Graph