Novak Brushless Motor: 55-5980-1.C__Manufacturing 3-Up Layout User Manual

Novak For the car

END BELL & BEARING REPLACEMENT INSTRUCTIONS:

1. Remove motor from vehicle & brush off any dirt (do not use motor cleaner).

2. Remove the front end bell/can/cap (end section of motor on the same side

as the pinion shaft) using a hex wrench to remove the three long socket

head cap screws, then slide it off the motor.

NOTE: The front bearing is secured in the end bell/end cap with a non-removable

locking agent. Removal of bearing can bend or damage the end bell/can/cap.

3. Remove the rotor by grasping the pinion shaft with pliers and carefully

pulling the rotor out of the motor.

Note: The rotor is the magnet in brushless motors and will attract metallic objects

(wrenches, washers, etc.)--place rotor on a soft cloth or towel to prevent damage.

–Most Novak motors have shim washers on the pinion end (& sometimes on

the back end) of the rotor to adjust free play--

Do Not lose these & re-install

them on the correct side of rotor.

Washers may be stuck to the bearing.

–Older SS series motors have brass spacers on both sides of rotor between

magnet & bearings--

Do not lose them & re-install them on the correct sides.

–Check condition of rotor--Careful to not damage electronics inside motor.

4. Clean inside motor using compressed air. (NO solvents or spray cleaners).

5. Note the timing setting of the motor. Newer Novak motors with

adjustable timing have a timing label on the side of the back end cap

and a timing notch machined into the back end bell/ring to indicate the

timing set point.

Make note of this to properly set timing during assembly.

6. Remove back end cap from motor using a hex wrench to remove the

3 flat head cap screws. The bearing on older plastic end cap motors is

held between the end cap and the sensor assembly

(beneath the power wire

tabs--

Note: Don’t rotate the sensor assembly)

--end cap may be slightly stuck due

to excess flux--gently pry end cap off if needed. Bearings on newer metal

end cap motors are pressed in and secured with a non-removable locking

agent--replacement bearing caps come with a factory-installed bearing.

7. On older plastic cap motors, remove rear bearing with small needle nose

pliers. Install new bearing into the recess in the plastic sensor assembly.

8. If your motor had a silicone sensor grommet inside the back bearing end

cap, insert it into the new end cap. Install new back bearing end cap

and re-install the flat head screws.

Hold the old end cap above the new

end cap to determine proper timing position. Install new timing label on

the side of end cap with proper timing mark aligned with the timing

notch in end bell/cap.

If changing wind type (Wye/Delta) in Ballistic8

motors, install new timing label directly over old label and then rotate

end cap to the other wind position (Y or D).

9. Re-install rotor, with shim washers/brass spacers on correct sides of

rotor

(short brass spacer goes on pinion side in SS motors)

.

Use a rolled-up piece of

a business card inserted down into stator to help align and insert rotor.

10. Remove insulator from old front end bell and insert it into new one.

11. Install new front end bell/can/cap by inserting the 3 long socket cap

screws into the new end bell/can/cap, aligning screws with slots in stator,

and threading into tapped holes in the back end bell/ring--

Check that

rotor spins freely as tightening screws--If binding occurs, disassemble

motor and determine cause. If it turns freely, firmly tighten the screws.

If screws do not have a patch of locking agent on threads, add a small drop to tips.

12. Re-check screw tension after a few runs. Check all 6 main screws.

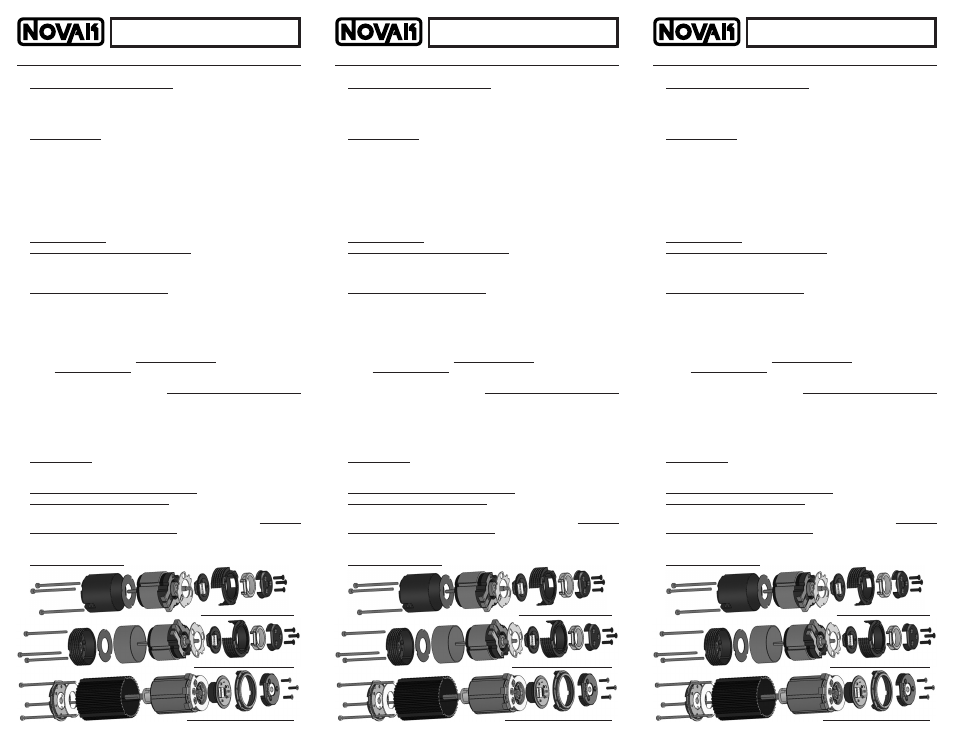

VULCAN EXPLODED VIEW

BALLISTIC EXPLODED VIEW

BALLISTIC 8 EXPLODED VIEW

END BELL & BEARING REPLACEMENT INSTRUCTIONS:

1. Remove motor from vehicle & brush off any dirt (do not use motor cleaner).

2. Remove the front end bell/can/cap (end section of motor on the same side

as the pinion shaft) using a hex wrench to remove the three long socket

head cap screws, then slide it off the motor.

NOTE: The front bearing is secured in the end bell/end cap with a non-removable

locking agent. Removal of bearing can bend or damage the end bell/can/cap.

3. Remove the rotor by grasping the pinion shaft with pliers and carefully

pulling the rotor out of the motor.

Note: The rotor is the magnet in brushless motors and will attract metallic objects

(wrenches, washers, etc.)--place rotor on a soft cloth or towel to prevent damage.

–Most Novak motors have shim washers on the pinion end (& sometimes on

the back end) of the rotor to adjust free play--

Do Not lose these & re-install

them on the correct side of rotor.

Washers may be stuck to the bearing.

–Older SS series motors have brass spacers on both sides of rotor between

magnet & bearings--

Do not lose them & re-install them on the correct sides.

–Check condition of rotor--Careful to not damage electronics inside motor.

4. Clean inside motor using compressed air. (NO solvents or spray cleaners).

5. Note the timing setting of the motor. Newer Novak motors with

adjustable timing have a timing label on the side of the back end cap

and a timing notch machined into the back end bell/ring to indicate the

timing set point.

Make note of this to properly set timing during assembly.

6. Remove back end cap from motor using a hex wrench to remove the

3 flat head cap screws. The bearing on older plastic end cap motors is

held between the end cap and the sensor assembly

(beneath the power wire

tabs--

Note: Don’t rotate the sensor assembly)

--end cap may be slightly stuck due

to excess flux--gently pry end cap off if needed. Bearings on newer metal

end cap motors are pressed in and secured with a non-removable locking

agent--replacement bearing caps come with a factory-installed bearing.

7. On older plastic cap motors, remove rear bearing with small needle nose

pliers. Install new bearing into the recess in the plastic sensor assembly.

8. If your motor had a silicone sensor grommet inside the back bearing end

cap, insert it into the new end cap. Install new back bearing end cap

and re-install the flat head screws.

Hold the old end cap above the new

end cap to determine proper timing position. Install new timing label on

the side of end cap with proper timing mark aligned with the timing

notch in end bell/cap.

If changing wind type (Wye/Delta) in Ballistic8

motors, install new timing label directly over old label and then rotate

end cap to the other wind position (Y or D).

9. Re-install rotor, with shim washers/brass spacers on correct sides of

rotor

(short brass spacer goes on pinion side in SS motors)

.

Use a rolled-up piece of

a business card inserted down into stator to help align and insert rotor.

10. Remove insulator from old front end bell and insert it into new one.

11. Install new front end bell/can/cap by inserting the 3 long socket cap

screws into the new end bell/can/cap, aligning screws with slots in stator,

and threading into tapped holes in the back end bell/ring--

Check that

rotor spins freely as tightening screws--If binding occurs, disassemble

motor and determine cause. If it turns freely, firmly tighten the screws.

If screws do not have a patch of locking agent on threads, add a small drop to tips.

12. Re-check screw tension after a few runs. Check all 6 main screws.

VULCAN EXPLODED VIEW

BALLISTIC EXPLODED VIEW

BALLISTIC 8 EXPLODED VIEW

END BELL & BEARING REPLACEMENT INSTRUCTIONS:

1. Remove motor from vehicle & brush off any dirt (do not use motor cleaner).

2. Remove the front end bell/can/cap (end section of motor on the same side

as the pinion shaft) using a hex wrench to remove the three long socket

head cap screws, then slide it off the motor.

NOTE: The front bearing is secured in the end bell/end cap with a non-removable

locking agent. Removal of bearing can bend or damage the end bell/can/cap.

3. Remove the rotor by grasping the pinion shaft with pliers and carefully

pulling the rotor out of the motor.

Note: The rotor is the magnet in brushless motors and will attract metallic objects

(wrenches, washers, etc.)--place rotor on a soft cloth or towel to prevent damage.

–Most Novak motors have shim washers on the pinion end (& sometimes on

the back end) of the rotor to adjust free play--

Do Not lose these & re-install

them on the correct side of rotor.

Washers may be stuck to the bearing.

–Older SS series motors have brass spacers on both sides of rotor between

magnet & bearings--

Do not lose them & re-install them on the correct sides.

–Check condition of rotor--Careful to not damage electronics inside motor.

4. Clean inside motor using compressed air. (NO solvents or spray cleaners).

5. Note the timing setting of the motor. Newer Novak motors with

adjustable timing have a timing label on the side of the back end cap

and a timing notch machined into the back end bell/ring to indicate the

timing set point.

Make note of this to properly set timing during assembly.

6. Remove back end cap from motor using a hex wrench to remove the

3 flat head cap screws. The bearing on older plastic end cap motors is

held between the end cap and the sensor assembly

(beneath the power wire

tabs--

Note: Don’t rotate the sensor assembly)

--end cap may be slightly stuck due

to excess flux--gently pry end cap off if needed. Bearings on newer metal

end cap motors are pressed in and secured with a non-removable locking

agent--replacement bearing caps come with a factory-installed bearing.

7. On older plastic cap motors, remove rear bearing with small needle nose

pliers. Install new bearing into the recess in the plastic sensor assembly.

8. If your motor had a silicone sensor grommet inside the back bearing end

cap, insert it into the new end cap. Install new back bearing end cap

and re-install the flat head screws.

Hold the old end cap above the new

end cap to determine proper timing position. Install new timing label on

the side of end cap with proper timing mark aligned with the timing

notch in end bell/cap.

If changing wind type (Wye/Delta) in Ballistic8

motors, install new timing label directly over old label and then rotate

end cap to the other wind position (Y or D).

9. Re-install rotor, with shim washers/brass spacers on correct sides of

rotor

(short brass spacer goes on pinion side in SS motors)

.

Use a rolled-up piece of

a business card inserted down into stator to help align and insert rotor.

10. Remove insulator from old front end bell and insert it into new one.

11. Install new front end bell/can/cap by inserting the 3 long socket cap

screws into the new end bell/can/cap, aligning screws with slots in stator,

and threading into tapped holes in the back end bell/ring--

Check that

rotor spins freely as tightening screws--If binding occurs, disassemble

motor and determine cause. If it turns freely, firmly tighten the screws.

If screws do not have a patch of locking agent on threads, add a small drop to tips.

12. Re-check screw tension after a few runs. Check all 6 main screws.

VULCAN EXPLODED VIEW

BALLISTIC EXPLODED VIEW

BALLISTIC 8 EXPLODED VIEW

Novak End Bell

(w/factory-installed bearing)

& Bearing Replacement

Novak End Bell

(w/factory-installed bearing)

& Bearing Replacement

Novak End Bell

(w/factory-installed bearing)

& Bearing Replacement