Novak HV Pro Set-Up (55-3221P-2) User Manual

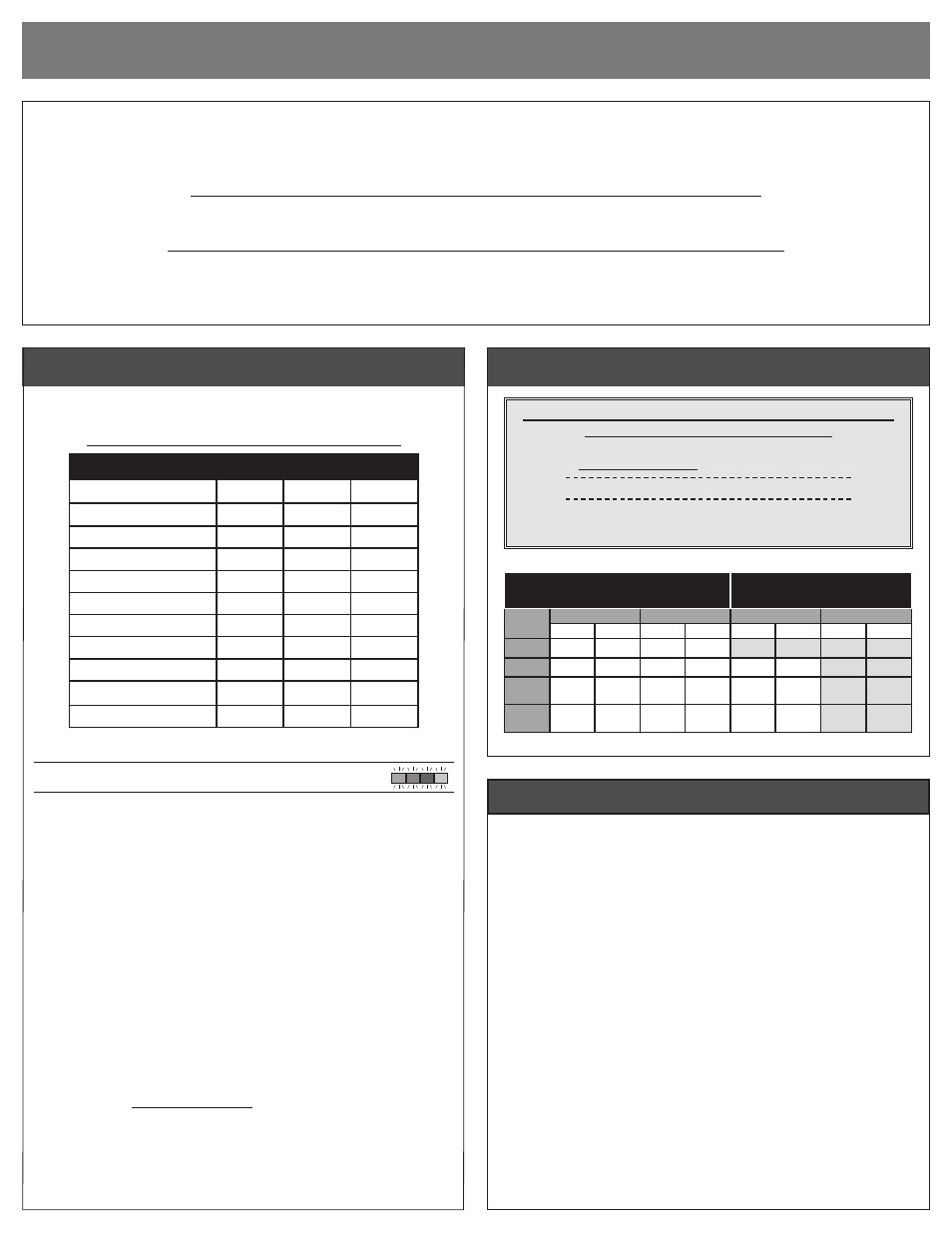

Proper gear selection throttle profile selection, Adjustable parameters, Throttle profile: #1 #2 #3

The HV Pro High-Voltage Brushless ESC is equipped with

3 user-

selectable Throttle Profiles (all programmable), as shown below.

HV PRO THROTTLE PROFILES:

Throttle Profile:

#1

#2

#3

w/Reverse

YES

NO

YES

Reverse %

100%

0%

25%

Minimum Brake

0%

0%

0%

Drage Brake

off

off

off

Dead Band

5%

5%

5%

Minimum Drive

1%

3%

1%

Throttle Curve

LInear

LInear

LInear

Brake Frequency

3kHz

3kHz

3kHz

Brakes

ON

ON

ON

Motor Rotation

CCW

q

CCW

q

CCW

q

LiPo Cut-Off

ON

ON

ON

NOTE: The HV Pro ESC is factory default set to Profile #1.

SELEcTINg THROTTLE PROFILES

:

all LEDs

NOTE: The HV Pro ESC will always revert back to Profile

#1 when the One-Touch set-up is performed.

With ESC on & connected to a charged battery (transmitter ON or OFF):

1. IF TRANSMITTER IS OFF, DISCONNECT ESC FROM RECEIVER

To avoid possible radio interference or signals from other transmitters,

remove ESC’s input signal harness from the receiver--Green & Red

LED will stay on to indicate no signal from receiver.

2. PRESS & HOLD THE ESC’S ONE-TOUCH SET BUTTON

Continue to hold SET button on ESC until all 4 LEDs turns on.

Note: You will continue holding past all the LED programming indicators in

the ESC’s software as shown in the flow chart on back side of this sheet.

3. RELEASE SET BUTTON AS SOON AS ALL 4 LEDs COMES ON

Once released, the 4 status LEDs will flash to indicate what

Throttle Profile is currently selected. The number of times the

LEDs flash indicates the Throttle Profile selection (1 of 5).

4. QUICK PRESS (& release) SET BUTTON TO CHANGE SELECTION

Each press will change ESC to the next consecutive Throttle Profile.

(After Profile 5, the sequence begins again at Profile 1)

Note: There is a time constraint during this selection process.

5. ESC STORES SELECTION & EXITS PROGRAMMING

If SET button is not pressed for 3 seconds,

ESC stores selected Throttle

Profile in its memory, exits to neutral, and is ready to go. (LEDs turn off

in a scrolling motion, then the Red LED turns on solid--Green LED will

be on if no transmitter signal present & Blue or Blue & Amber LEDs on

if Drag or Minimum Brakes are above 0%).

HV PRO cUSTOM PROgRAMMINg & PROPER gEAR SELEcTION SHEET

PROPER gEAR SELEcTION

THROTTLE PROFILE SELEcTION

4-2008

Motor operating temperature is the ONLY way

to properly set vehicle gearing

The Motor and Speed Control should not exceed

160-170°F MAX at end of the run!

Change the gearing to avoid overheating!

DO NOT FREE-REV MOTOR!

Free-running your brushless motor in a no-load condition can cause rotor failure

& ESC transistor damage and will void the product’s warranty.

ADjUSTAbLE PARAMETERS

In addition to several items that can be turned on & off, many ESC parameters

are adjustable. Here are some parameter descriptions that can help you fine

tune the ESC to your requirements:

MINIMUM bRAKE (1 of 10 settings from 0 to 30%)--The amount of braking

applied with the first pulse of transmitter throttle information.

--Raising this setting starts the braking at a stronger/higher level.

--Setting the Minimum Brake turns off the Drag Brake feature.

DRAg bRAKE (1 of 10 settings from 0% {off} to 30%)--Amount of braking

applied while transmitter is at neutral. Known as ‘coast’ or ‘auto’ brakes.

--Raising this setting makes the motor slow down more, without pushing the

transmitter’s trigger into the brake/reverse direction.

**With Drag Brake on setting 2-10, Min. Brake value is same as Drag Brake value

DEAD bAND (1 of 5 settings from 2 to 6%)--The space between Minimum

Brake and Minimum Drive, with neutral in the middle.

--Raising this setting will increase the ‘free play’, or distance your trigger must

move before forward drive or braking will begin--Can be helpful to resolve minor

“glitching” issues when the vehicle is in neutral.

MINIMUM DRIVE (1 of 5 settings from 1 to 12%)--The amount of forward

drive applied with the first pulse of transmitter throttle information.

--Raising this setting makes the motor start at a stronger/higher level so it takes

off more aggressively from neutral.

THROTTLE cURVE (1 of 2 settings--Linear & Expo)--The response of

the motor to transmitter throttle information being sent to it.

--Expo setting provides smoother, more controlled low-end power delivery.

bRAKE FREQUENcY (1 of 7 settings from 1 to 8kHz)--Frequency the

braking duty cycle information in being sent to the motor.

--Raising this setting makes the braking feel smoother and easier to control.

--Decreasing this setting makes the braking feel more abrupt or ‘grabbier’.

P5

Recommended Gearing for Traxxas

®

E-Maxx

™:

New Version Traxxas

E-Maxx™

Motor Heat Sink Must be Trimmed

Original Traxxas

®

E-Maxx™

Use First gear for Shaded Areas

NOVAK

MOTOR

12-cell NiMH / 4S LiPo

14 cell NiMH

12-cell NiMH / 4S LiPo

14 cell NiMH

Spur

Pinion

Spur

Pinion

Spur

Pinion

Spur

Pinion

HV4.5

68

13

68

12

66-68

18

66-68

16

HV5.5

68

14

68

13

74-76

14

66-68

18

HV6.5

68

15

68

14

70-72

74-76

14

15

64-66

18

HV7.5

68

16

68

15

70-72

74-76

15

16

64-66

20

See www.teamnovak.com for updated gearing charts & final drive ratios

The

Novak HV Pro High-Voltage Brushless ESC includes 3 Fully Programmable Throttle Profiles (2 w/Reverse & 1 w/without) and has

on-board programming for extreme versatility & fine-tuning of

Minimum Brake, Drag Brake, Dead Band, Minimum Drive, Throttle Curve,

Brake Frequency, Brake Disable, Motor Rotation, and LiPo Cut-Off--all at the touch of a button!

This ESC is compatible with 6-14 NiMH or 2-4S LiPo cells. Novak’s exclusive

Smart-Stop LiPo Cut-Off Circuitry is built-in and

when active, it automatically switches to the proper LiPo cut-off voltage for the battery packs you connect.

IMPORTANT! If using dual battery packs, and upgrading or replacing the connectors, it is critical that you replace one connector

at a time to avoid improper wiring and cross-connection of battery leads, which will damage ESC and void the warranty.

(We recommend using Novak 4mm Hi-Amp Connectors (#5740 or 5741) or other high-quality connectors like the Deans® Ultra Plug

TM

)

The motors that come in Novak HV brushless systems

now include heavy-duty 5mm output shafts that are recommended for use with

Novak 1/8th Scale Conversion Kits

(Novak part #5010-5019)

and other power-hungry monster vehicles. Novak HV motors feature high-

strength sintered neodymium rotors for optimum performance. Novak offers

5mm Mod 1 & 32 Pitch Steel Pinion Gears for use with the

5mm shaft equipped HV motors

(5mm Mod 1 Gears available in Novak part #5100-5110; 5mm 32 Pitch Gears available in Novak part #5152-5157)

.

#55-3221P-2

8-2008