Garelick 71053 MOTOR BRACKET User Manual

Page 2

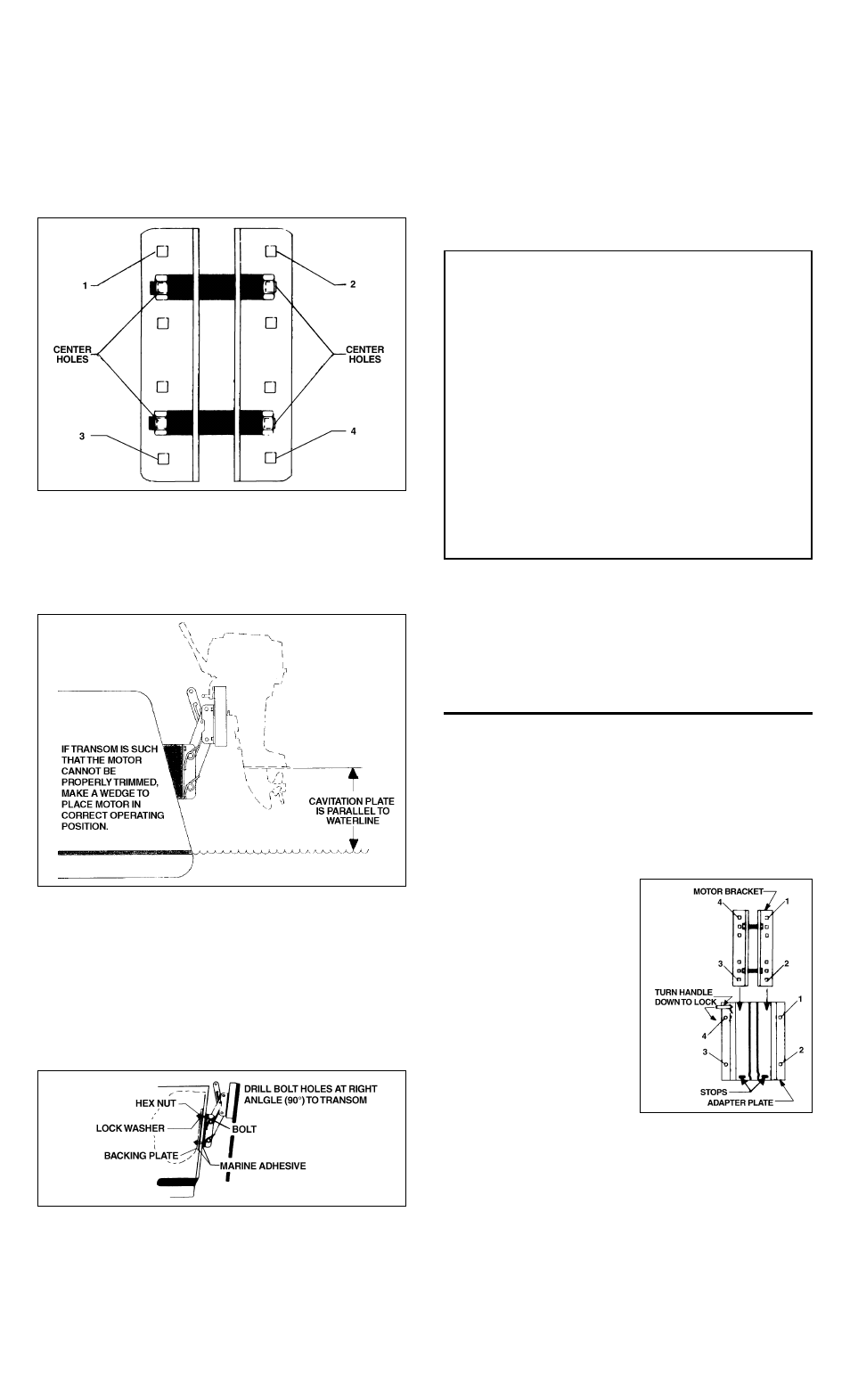

Refer to Fig. 5

After the bracket has been properly positioned, mark the four

outside hole locations using the bracket as a template on your

transom (See Fig. 5). NOTE: If it is necessary to use the center

holes on the bracket, you must reverse the mounting bolts so

their heads will be on the inside of the transom. Drill the four

marked 3/8" holes, making sure to hold the drill at right angles

to the transom when drilling.

Refer to Fig. 6

Check the angle of the transom on your boat and determine if

the motor to be used can be trimmed so the cavitation plate is

parallel to the waterline. If not make a wedge out of suitable

material to do so or, use an EEZ-IN Adjustable Angle Bracket

Model 71045.

Refer to Fig. 7

If your transom is less than 2" thick, it is recommended that a

backing plate be made and mounted on the inside of the

transom for needed rigidity. Attach your motor bracket to the

transom by coating the inside surfaces of the mounting flanges

and backing plate with a marine adhesive/sealant compound

and then squeeze a small amount into each bolt hole on both

sides of the transom. Secure the bracket to the transom as

illustrated. The bracket is now ready for motor mounting.

OPERATING INSTRUCTIONS

To move bracket bear down on motor, release locking lever by

pushing Handle towards the mounting board, allowing the

guide pin to slide in its safety groove. Bracket will snap locked

when fully extended in its “up” or “down” position. The bracket

springs counter most of the motor weight; however, a slight

push or lift is necessary to equalize this. ALWAYS LOWER

MOTOR SLOWLY.

All four arm bolts on the bracket should be

tight, but not too much to prevent desirable up and down

action.

IMPORTANT RECOMMENDATIONS

A grease coating on all bolts and nuts will further increase

resistance to corrosion. Keep pivoting points lubricated.

Remove your motor from the bracket when trailering your boat.

Use a safety cable when operating your motor. Keep wood

block sealed and varnished to increase longevity.

MODEL 71053 ADAPTER PLATE MOUNTING INSTRUCTIONS

1. Check hardware packet for the following mounting

hardware:

4 - 5/16 x 3" stainless steel carriage bolts

4 - 5/16" stainless steel lockwashers

4 - 5/16" stainless steel hexnuts

Prior to installation, be certain to read instructions

completely.

2. Slide motor bracket into

adapter plate as

illustrated in Fig. 8 and

secure it in position by

turning locking handle as

indicated in Fig. 8.

3. Follow mounting instruc-

tions for Outboard Motor

Bracket on the reverse

side to correctly Position

unit. NOTE: Disregard

bracket’s hardware pack-

et and use supplied

packet with adapter

plate. For mounting use

the adapter’s holes as a

template.

INSTALLATION INSTRUCTIONS FOR A MOUNTED MOTOR

BRACKET

If your adapter plate is to be used with a mounted outboard

motor bracket, remove your bracket from the boat and seal the

existing holes with plugs and a marine adhesive/sealant.

Position the plate on the transom so the bracket will be in the

same position as before. Follow Steps 5-7 for the Outboard

Motor Bracket to secure the plate in place.

FIG. 7

FIG. 5

FIG. 8

FIG. 6

AUXILIARY OUTBOARD MOTOR BRACKET

IMPORTANT CAUTION GUIDELINES

1. Install motor bracket only in “up” position.

2. Always remove your motor from the bracket when

trailering. Failure to do so could result in damage to

boat, motor and bracket.

3. Do not exceed the stated H.P. rating or weight.

4. Use a safety cable when operating your motor.

5. Operate motor at low speed.

6. Avoid turning motor at full throttle, refrain from sharp

turns.

7. Operate motor in lowest position possible for best

performance.

8. Always raise and tilt motor when not in use.

9. Keep pivoting bolts greased to insure smooth operation.