FloAire Indirect Fired Heater User Manual

Page 8

8

Gas Pressure Table

Gas Pressure Type

Gas Pressure

Inlet Pressure - Natural Gas

7 in. w.c. – 14 in. w.c.

Inlet Pressure - Propane

11 in. w.c. – 14 in. w.c.

Max. Manifold Pressure - Natural Gas

3.5 in. w.c. maximum

Max. Manifold Pressure - Propane

10 in. w.c. maximum

Min. Manifold Pressure - Natural Gas

0.56 in. w.c. maximum

Min. Manifold Pressure - Propane

1.6 in. w.c. maximum

Gas Connection Sizes

Unit Size

Gas Pipe Size (NPT)

Size 1

¾”

Size 2

1”

Size 3

1”

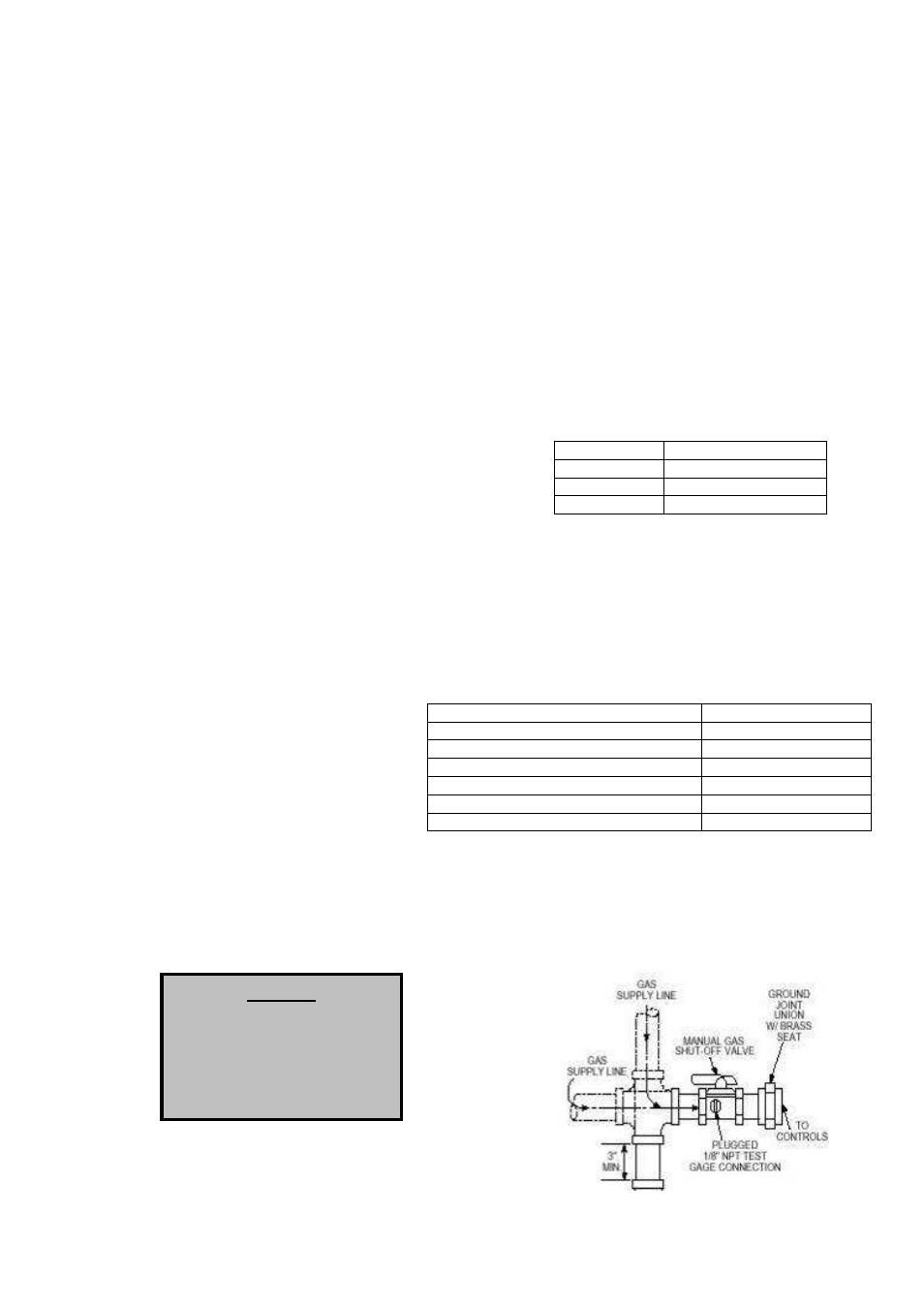

Gas Connection Diagram

Gas

Installation of gas piping must conform with local building codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54) – latest edition. In Canada, installation must be in

accordance with CAN/CGA-B149.1 for natural gas units and CAN/CGA-B149.2 for propane units.

WARNING: INLET GAS PRESSURE MUST NOT EXCEED 14 IN. W.C. SEE UNIT

RATING PLATE FOR PROPER GAS SUPPLY PRESSURE AND GAS TYPE.

1. Always disconnect power before working on or near a heater. Lock and tag the disconnect

switch or breaker to prevent accidental power up.

2. Piping to the unit should conform with local and national requirements for type and volume of gas

handled, and pressure drop allowed in the line. Refer to the Gas Engineer’s Handbook for gas

line capacities.

3. The incoming pipe near the heater should be sized to

match the connection on the outside of the unit. Unit

inlet sizes are shown in the table to the right. Avoid

multiple taps in the gas supply so the unit has a steady

supply of gas at all times.

4. Install a ground joint union with brass seat and a

manual shut-off valve external to the unit casing, as

shown below, adjacent to the unit for emergency shut-off and easy servicing of controls.

5. Provide a sediment trap, as shown below, before each unit and where low spots in the pipe line

cannot be avoided.

6. Blow out the gas line to remove debris before making connections. Purge line to remove air

before attempting to start unit. Purging of air from gas lines should be performed as described in

ANSI Z223.1-latest edition “National Fuel Gas Code”, or in Canada in CAN/CGA-B149.

7. All field gas piping must be pressure/leak tested prior to unit operation. Use a non-corrosive

bubble forming solution or equivalent

for leak testing. The heater and its

individual shut-off valve must be

disconnected from the gas supply

piping system during any pressure

testing of that system at test

pressures in excess of ½ psi. The

heater must be isolated from the gas

supply piping system by closing its

individual

manual

shutoff

valve

during any pressure testing of the

gas supply piping system at test pressures equal to or less than ½ psi. This must be performed

on an annual basis.

8. This unit requires a constant 7 in. w.c. minimum natural gas supply, (LP should be 11 in. w.c.

minimum) when the unit is operating at maximum gas flow. If the gas supply exceeds 14 in.

w.c. it will damage the internal valve components, and if it is below 7 in. w.c., the heater may not

perform to specifications.

NOTICE

Refer to the heater rating

plate for determining the

minimum

gas

supply

pressure for obtaining the

maximum gas capacity for

which this heater is specified.