Sequence of operation, Maxitrol amplifier pulley combination chart, Modulating gas system – FloAire Indirect Fired Heater User Manual

Page 16

16

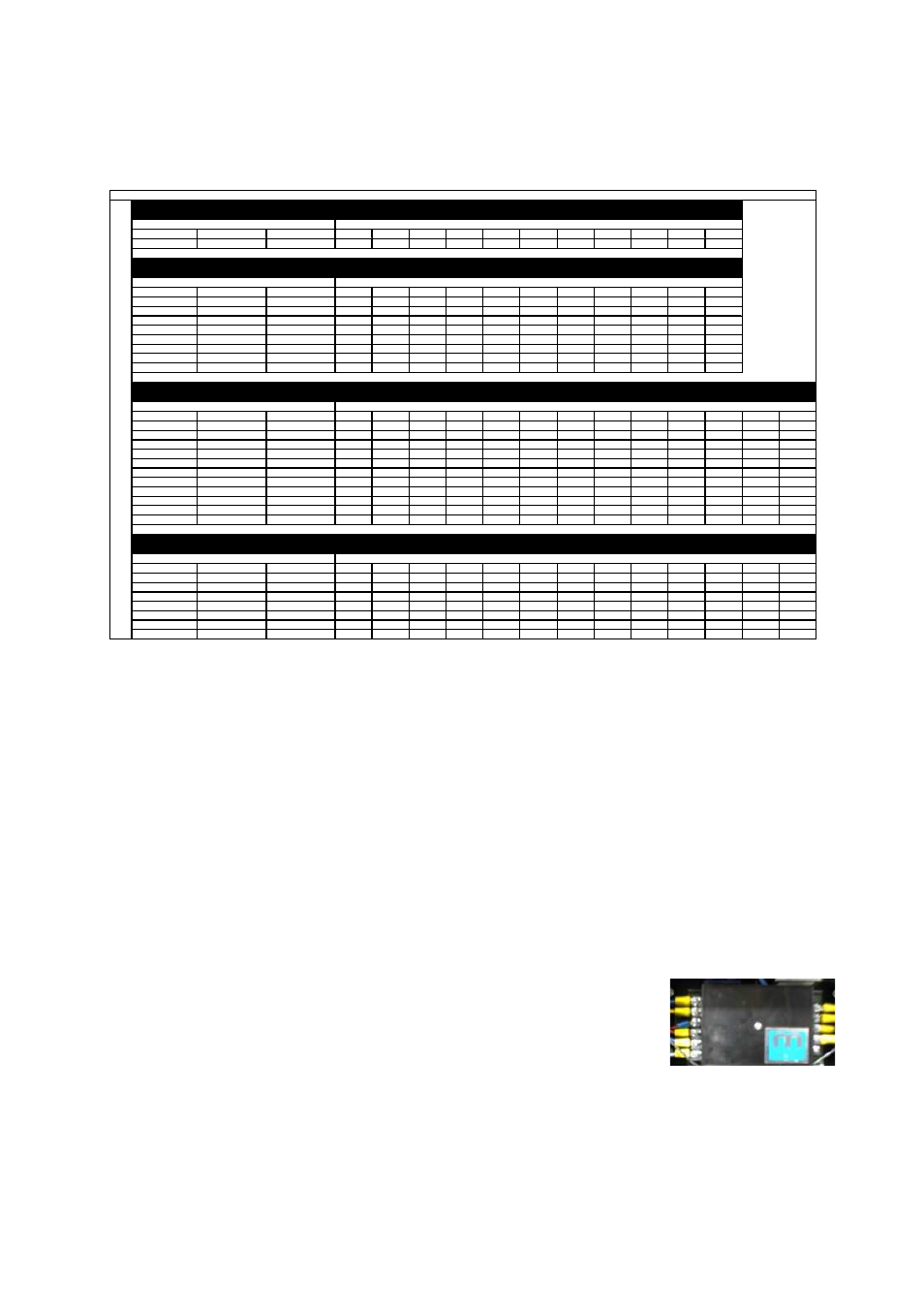

Maxitrol Amplifier

Pulley Combination Chart

Motor RPM

1725

1/3 to 1-1/2 HP

MOTOR PULLEY

Dd1

Dd2

Pd1

Pd2

AX BELTS

1VL34

1.9

2.9

2

3

Open

Closed

BLOWER PULLEY

DATUM DIAMETER

PITCH DIAMETER

5

4 1/2

4

3 1/2

3

2 1/2

2

1 1/2

1

1/2

0

AK114

11

11.2

308

323

339

354

370

385

400

416

431

447

462

1/3 to 2 HP

MOTOR PULLEY

Dd1

Dd2

Pd1

Pd2

AX BELTS

1VL40

2.4

3.4

2.6

3.6

Open

Closed

BLOWER PULLEY

DATUM DIAMETER

PITCH DIAMETER

5

4 1/2

4

3 1/2

3

2 1/2

2

1 1/2

1

1/2

0

AK114

11

11.2

400

416

431

447

462

477

493

508

524

539

554

AK94

9

9.2

488

506

525

544

563

581

600

619

638

656

675

AK79

7.5

7.7

582

605

627

650

672

694

717

739

762

784

806

AK66

6.2

6.4

701

728

755

782

809

836

863

889

916

943

970

AK54

5

5.2

863

896

929

962

995

1028

1062

1095

1128

1161

1194

AK46

4.2

4.4

1019

1059

1098

1137

1176

1215

1255

1294

1333

1372

1411

AK39

3.5

3.7

1212

1259

1305

1352

1399

1445

1492

1539

1585

1632

1678

AK32

3

3.2

1402

1455

1509

1563

1617

1671

1725

1779

1833

1887

1941

3 to 5 HP

MOTOR PULLEY

Dd1

Dd2

Pd1

Pd2

BX BELTS

2VP42

2.9

3.9

3

4

Open

Closed

BLOWER PULLEY

DATUM DIAMETER

PITCH DIAMETER

6

5 1/2

5

4 1/2

4

3 1/2

3

2 1/2

2

1 1/2

1

1/2

0

2BK160H

15.4

15.7

330

339

348

357

366

375

385

394

403

412

421

430

439

2BK140H

13.4

13.7

378

388

399

409

420

430

441

451

462

472

483

493

504

2BK120H

11.4

11.7

442

455

467

479

491

504

516

528

541

553

565

577

590

2BK110H

10.4

10.7

484

497

511

524

537

551

564

578

591

605

618

631

645

2BK100H

9.4

9.7

534

548

563

578

593

608

622

637

652

667

682

697

711

2BK90H

8.4

8.7

595

611

628

644

661

677

694

710

727

744

760

777

793

2BK80H

7.4

7.7

672

691

709

728

747

765

784

803

821

840

859

877

896

2BK70H

6.4

6.7

772

794

815

837

858

880

901

923

944

965

987

1008

1030

2BK60H

5.4

5.7

908

933

958

984

1009

1034

1059

1084

1110

1135

1160

1185

1211

2BK55H

4.9

5.2

995

1023

1050

1078

1106

1133

1161

1189

1216

1244

1272

1299

1327

2BK50H

4.4

4.7

1101

1132

1162

1193

1223

1254

1285

1315

1346

1376

1407

1438

1468

7-1/2 to 10 HP

MOTOR PULLEY

Dd1

Dd2

Pd1

Pd2

BX BELTS

2VP60

4.3

5.5

4.7

5.9

Open

Closed

BLOWER PULLEY

DATUM DIAMETER

PITCH DIAMETER

6

5 1/2

5

4 1/2

4

3 1/2

3

2 1/2

2

1 1/2

1

1/2

0

2BK160H

15.4

15.7

516

527

538

549

560

571

582

593

604

615

626

637

648

2BK140H

13.4

13.7

592

604

617

630

642

655

667

680

693

705

718

730

743

2BK120H

11.4

11.7

693

708

722

737

752

767

781

796

811

826

840

855

870

2BK110H

10.4

10.7

758

774

790

806

822

838

854

871

887

903

919

935

951

2BK100H

9.4

9.7

836

854

871

889

907

925

943

960

978

996

1014

1031

1049

2BK90H

8.4

8.7

932

952

972

991

1011

1031

1051

1071

1091

1110

1130

1150

1170

2BK80H

7.4

7.7

1053

1075

1098

1120

1143

1165

1187

1210

1232

1255

1277

1299

1322

TURNS ON MOTOR PULLEY

TURNS ON MOTOR PULLEY

1

0

-

1

8

I

N

.

B

L

O

W

E

R

TURNS ON MOTOR PULLEY

TURNS ON MOTOR PULLEY

Sequence of Operation

The Indirect-fired heater is most easily understood when broken down into smaller individual systems.

There are two main systems, a make-up air fan and a heater. The make-up air fan consists of a heavy-

duty blower and motor. The heater may be further broken down into two control systems, the Flame

Safety Control (FSC) and the Modulating Gas System (MGS). The burner mixes air with the gas (Natural

or Propane) which heats a heat exchanger which heats the air.

Modulating Gas System

The first system, the Maxitrol modulating gas system, consists of a

temperature selector dial, a discharge air sensor, an amplifier, and a modulating

gas valve. The two types of Maxitrol systems found on these units are the

Maxitrol 20/30 and the Maxitrol 21/31. The 20 and 21 series are for single

furnace arrangement and the 30 and 31 series are for multiple furnace

arrangement. The Maxitrol 21/31 utilizes a discharge air sensor and modulates

the discharge air to the selected temperature on the temperature selector dial.

The Maxitrol 20/30 utilizes a room temperature sensor/selector in order to

control the room temperature. The modulating gas valve controls the amount of gas to the burner based

on the temperature rise needed. When the modulating gas valve is all the way open and achieving the

maximum BTUs and temperature rise of the unit, it is called “high fire”.