Components – FloAire Indirect Fired Heater User Manual

Page 19

19

Components

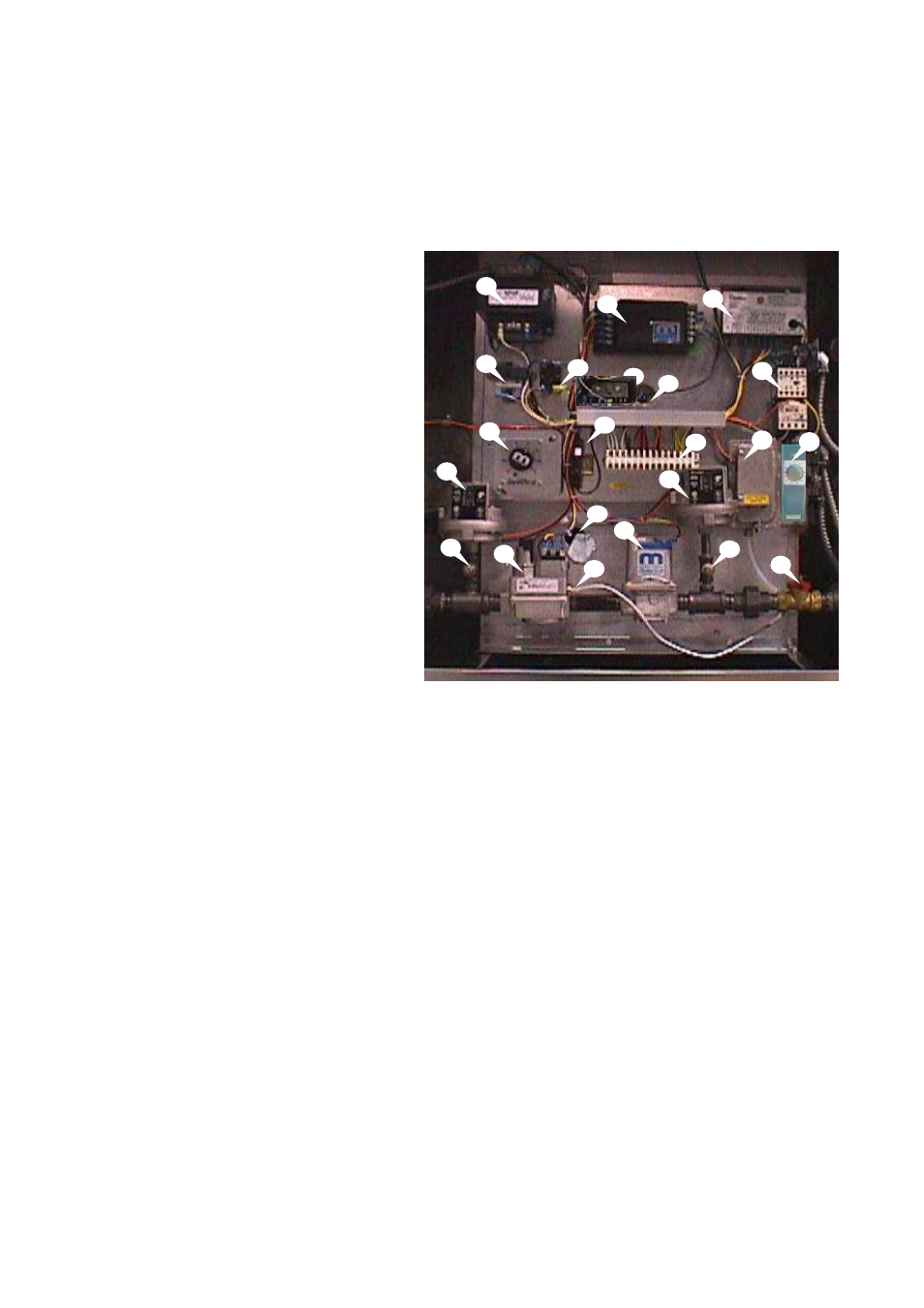

The following image and list outlines the typical in-direct fired heater components and their functions.

1. Power Transformer – Installed

when motor voltage > 120V. Used

to provide 120V service to controls.

2. Control

Transformer

–

120V

primary; 24V secondary control

transformer.

3. Discharge Temperature Set-Point

–

Controls

the

discharge

air

temperature. Furnace will not light if

air temperature is higher than set-

point.

4. Low

Gas

Pressure

Switch

(Optional) – De-energizes furnace

controls if gas pressure falls below

its set-point.

5. Inlet Gas Pressure Tap – Inlet gas

pressure should be measured here.

6. Combination

Gas

Valve - A

combination of redundant solenoid

valves, pilot valve and gas regulator

built into one unit.

7. Power Vent Relay – Energizes

power vent motor on call for heat.

8. Maxitrol Modulating Amplifier -

Regulates

temperature

by

modulating gas valve

9. Freeze-Stat Thermostat (Optional) – De-energizes blower motor if the discharge air

temperature falls below the set point.

10. Circuit Breaker – Protects electrical components from high current spikes.

11. Burner View Port – Allows burner to be monitored.

12. Pilot Tubing – Pilot tube connection to combination gas valve.

13. Automatic Reset Thermal Limit – Safety device that prevents the furnace from overheating.

14. Modulating Gas Valve – Modulates gas flow to burner to provide proper air temperature.

15. High Gas Pressure Switch (Optional) – De-energizes furnace controls if gas pressure rises

above its set-point.

16. Terminal Strip – Central location to terminate control wiring. Should be used for troubleshooting.

17. Flame Safety Control – Initiates and monitors flame.

18. Motor Starter – Contactor with overload protection to start and protect motor.

19. Airflow Switch – A safety device insuring proper air flow during furnace operation.

20. Manifold Gas Pressure Tap – Manifold gas pressure should be measured here.

21. Manual Gas Shut-Off Valve Allows gas flow to burner to be shut off to leak test gas train

22. Intake Thermostat – Used on Models with two furnaces. Cycles second (downstream) furnace

on and off with fluctuations in intake air temperature. Should be set to [Temp Discharge set point

minus temp rise of first heat exchanger plus 5 degrees F)

1

4

3

2

8

17

18

5

21

10

11

20

19

12

7

9

15

6

14

16

13

22