FloAire Indirect Fired Heater User Manual

Page 12

12

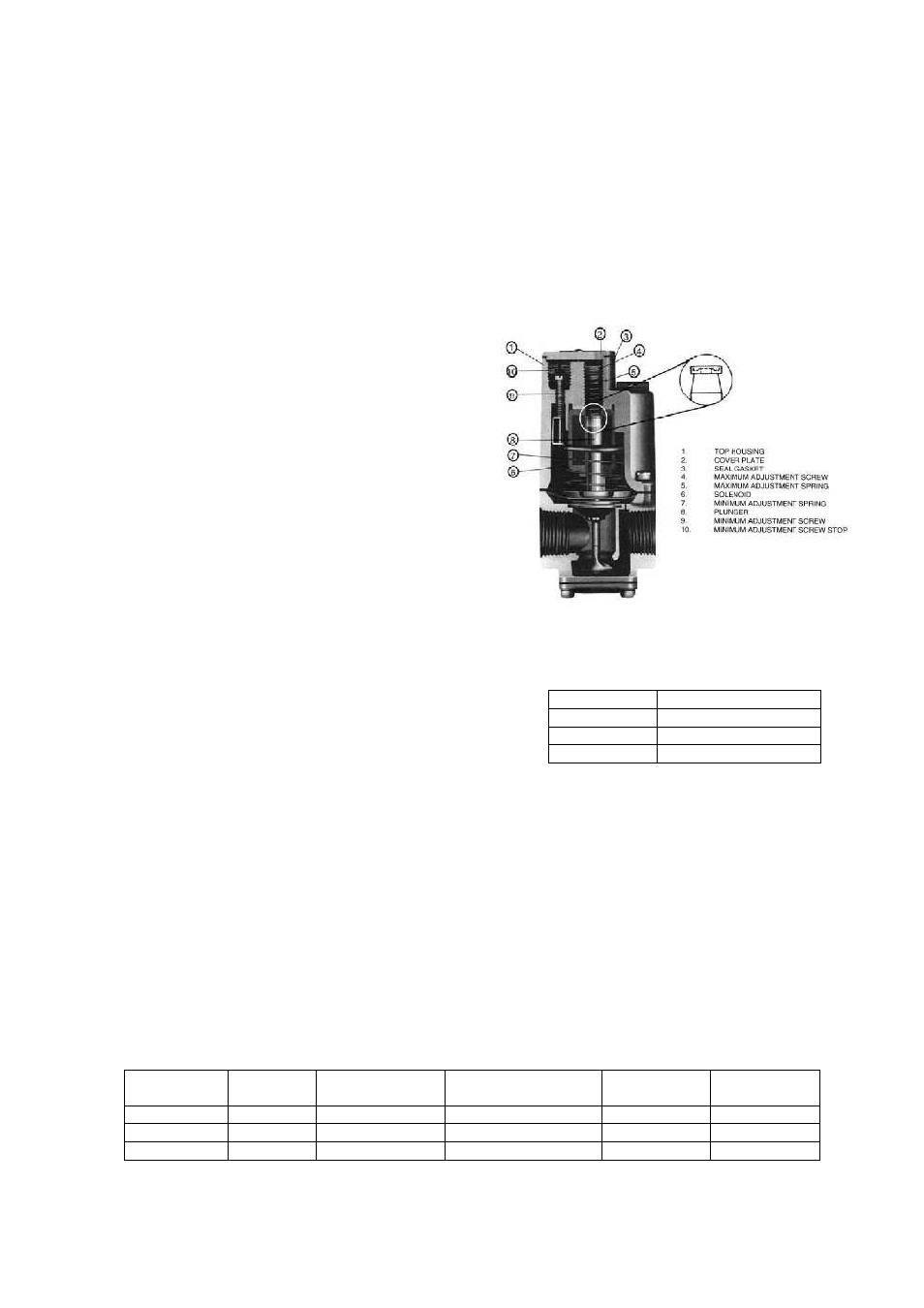

Maxitrol Modulating Valve

Orifice and Gas Consumption Chart

Furnace

Size

No. of

Orifices

Natural Gas

Orifice Drill Size

Propane Gas Orifice

Drill Size

Natural Gas

CFH

Propane Gas

CFH

200

3

23

40

192.3

80

350

6

27

43

336.5

140

400

6

23

40

384.6

160

Mod Valve Voltage Summary

Volts DC

Firing Mode

0 to 2 VDC

High Fire

2 to 14 VDC

Modulation

14 to 20 VDC

Low Fire

Main Burner Adjustment

1. Once the pilot has been properly established, the manifold gas pressure should be adjusted to

jobsite conditions. The gas pressure regulator (integral to the combination gas control) is

adjusted at the factory for average gas conditions. It is important that the gas be supplied to the

furnace in accordance with the input rating on

the rating plate.

2. Create a high fire call for heat. This should be

done with the blower on and all gas controls

on. High fire can be achieved by removing the

wire at terminal #3 from the Maxitrol amplifier

(0 VDC to modulating valve).

3. The manifold pressure should be checked at

the

pressure

tap

downstream

of

the

modulating valve. For natural gas systems,

the high fire manifold pressure should be set

at 3.5 in. w.c. For propane gas, the high fire

manifold pressure should be set to 10 in. w.c.

4. Remove the cap of the modulating valve.

Using the maximum adjustment screw, adjust

the high fire manifold pressure to 3.5 in. w.c.

for natural gas and 10 in. w.c. for propane gas.

If the high fire screw is at the end of its

adjustment and more pressure is needed, then

adjust the main gas pressure regulator spring

(on the combination valve) to achieve the

proper manifold pressure. Turning the

regulator screw clockwise will increase pressure and

counter-clockwise will decrease pressure.

5. Reconnect the wire on the Maxitrol amplifier at terminal

#3.

6. The low fire manifold pressure must now be set. This

is done by first moving the wire from terminal #11 on

the Maxitrol amplifier to terminal #10. The temperature

set-point should be set to its minimum set-point. Place

a jumper wire between terminal #3 and terminal #4 on the Maxitrol amplifier.

7. Using the minimum adjusting screw, adjust low the low fire manifold pressure to 0.56 in. w.c. for

natural gas and 1.6 in. w.c. for propane gas. Replace the cap to the Maxitrol valve and restore

all of the original wiring on the Maxitrol amplifier and gas components.

8. The main burner flame can be viewed after loosening and pushing aside the gas designation disc

on the side of the burner box. The appearance of the flame can be adjusted by changing the

manifold air shutters. To increase primary air, loosen the air shutter set screws and move the air

shutters closer to the manifold. To decrease primary air, move the air shutters away from the

manifolds. Retighten set screws after adjustment. Proper operation provides a soft blue flame

with a well-defined inner core. A lack of primary air will produce soft, yellow tipped flames.

Excess primary air produces short, well-defined flames with a tendency to lift off the burner ports.

9. A final gas leak check shall be performed to verify the gas-tightness of the heater’s components

and piping under normal operating conditions.