D.A.S. Audio Aero 48 User Manual

Page 7

3. ASSEMBLING AN ARRAY

3.1TRANSPORTING THE CABINETS

AERO-48 units can be transported by using

the front panel dolly PL-48 or by using the PL-48S steel

dolly which can transport a maximum of 3 AERO-48

stacked in an arc or 4 units stacked vertically.

The Aero-218SUB can be transported on the

rear located casters. Their rectangular shape

facilitates stacking without the use of the rigging

hardware.

3.2 PLANNING/INSPECTION

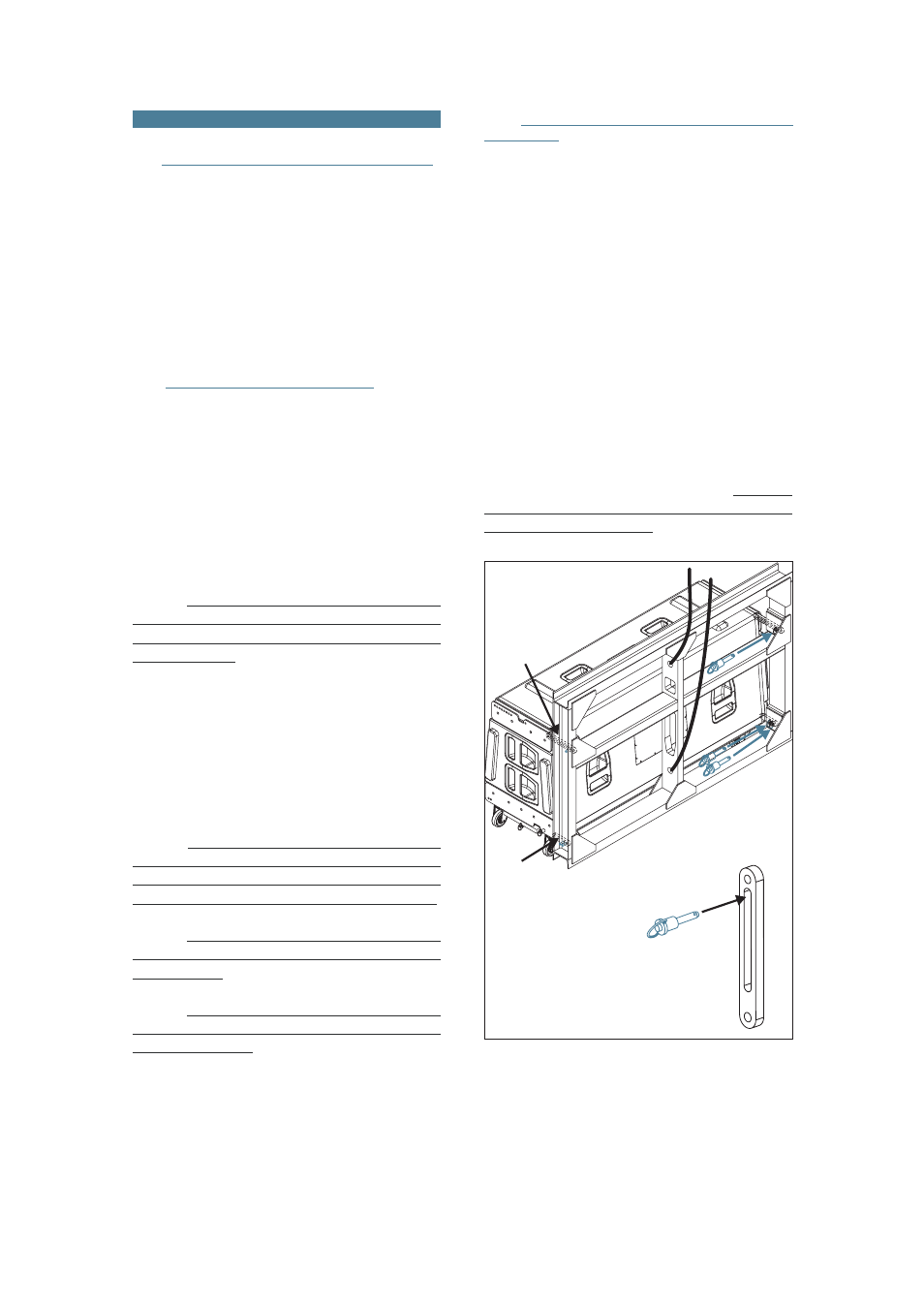

3.3 ASSEMBLING AN ARRAY “ONE

BY ONE”

When few units are to be used (minimum

systems recommended is 6 units) or when the dolly

platforms cannot be used due to a lack of space, the

enclosures will have to be hung “one by one”. The first

step will to attach the AX-AERO48 grid structure to

the hoists. The chain slings need to be attached to the

structure using the shackles provided with the grid.

Once this has been accomplished, the grid structure

can be placed in a vertical position by lifting the rear

hoist and lowering the front hoist so that the rear of

the grid is on top and the front of the grid at the

bottom, ready to receive the first box.

The next step is to attach the first unit to the

grid by introducing the G1A48 and G2A48 guides in

the receiving points of the grid structure and assuring

them with the six safety pins. The safety pins should

be inserted in the slot of the G2A48. It is very

important to make sure that the pins have been

inserted and locked correctly.

AX-AERO48

AERO-48

G1A48

G2A48

1

2

3

4

5

6

The quick release pins(3 and 4) must be

inserted through the slot of G2A48

3 + 4

Once the first unit of the array has been

attached to the AX-AERO48, the assembly should be

lifted by way of the rear hoist until the wheels of the

PL-48 dolly platform lift off the ground. From this point

on, the front hoist can be used to lift the box into a

horizontal position.

Before installing the AERO systems it is a

good idea to run a simulation with the AEROWARE

program utilizing the venue dimensions. This way we

can determine the needs that should be met by the

rigging structures such as hoists, cranes, beams,

rigging points, etc. Besides providing weight

information, the program also provides users with

splay angle information, safety pin positions and

coverage predictions.

Inspection is the next step after planning

and acquiring all the necessary parts needed to

elevate the systems. All parts, including the hardware

attached to the enclosure, the safety pins, etc. should

be thoroughly inspected before each use. Units

exhibiting deformations, cracks or any other defect

should be replaced with new units.

It is extremely important to assure that each

and every one of the aforementioned structures is

capable of supporting a superior load than that of the

complete system.

It is important to establish an inspection

routine for the complete rigging system before each

event or installation as well as establishing the

maximum load specifications of the hoists to be used.

Rigging should be carried out by experts

familiar with the way the systems function and their

characteristics.

On occasions, it may be convenient to have

additional tie down points to impede the array from

twisting or swinging.

Aero-48

Manual del usuario/ User´s manual

34