Troubleshooting – Carrier 38GXC User Manual

Page 16

16

TROUBLESHOOTING

This section provides the required flow charts to troubleshoot problems that may arise.

NOTE: Information required in the diagnoses can be found either on the wiring diagrams or in the appendix.

Required Tools:

The following tools are needed when diagnosing the units:

S

Digital multimeter

S

Screw drivers (Phillips and straight head)

S

Needle--nose pliers

Recommended Steps

1. Refer to the diagnostic hierarchy chart below and determine

the problem at hand.

2. Go to the chart listed in the diagnostic hierarchy and follow

the steps in the chart for the selected problem.

Error codes, if they occur, are displayed on the LED panel on the front cover of the unit. In addition, some of the same errors are displayed

by flashing LEDs on the outdoor board. If possible, always check the diaganostic codes displayed on the indoor unit first.

For problems requiring measurements at the control boards:

1. Always disconnect the main power.

2. When possible check the outdoor board first.

3. Start by removing the outdoor unit top cover.

4. Reconnect the main power

5. Probe the outdoor board inputs and outputs with a digital

multi--meter referring to the wiring diagrams and

input/output charts found in the appendix.

6. Connect the red probe to hot signal and the black probe to

the ground or negative.

7. Note that some of the DC voltage signals are pulse will give

continuously variable readings.

8. If it is necessary to check the indoor unit board you must

start by disconnecting the main power.

9. Next remove the front cover of the unit and then control

box cover.

10. Carefully remove the indoor board from the control box,

place it face up on a plastic surface (not metal).

11. Reconnect the main power and repeat steps 5,6, and 7.

12. Disconnect main power before reinstalling board to avoid

shock hazard and board damage.

For problems requiring pressure measurements:

1. Connect the low pressure gauge to the gauge connection

port on the suction service valve

2. Set compressor speed using the system remote control as

follows:

COOLING – Select a set point of 66_F and push the sleep

button 4 times

HEATING – Select a set point of 84_F and push the sleep

button 4 times

3. With the system operating at steady state conditions, make

the following measurements:

a. Outdoor ambient temperature

b. Compressor discharge temperature as close to the

compressor as possible

c. Suction pressure

4. Refer to the Appendix and select a suction pressure and

discharge temperature range based on the outdoor ambient

temperature for either cooling or heating. Compare the

measured pressure and temperature to the values in the chart

to determine if the operating pressures and temperatures of

the systems are normal or not.

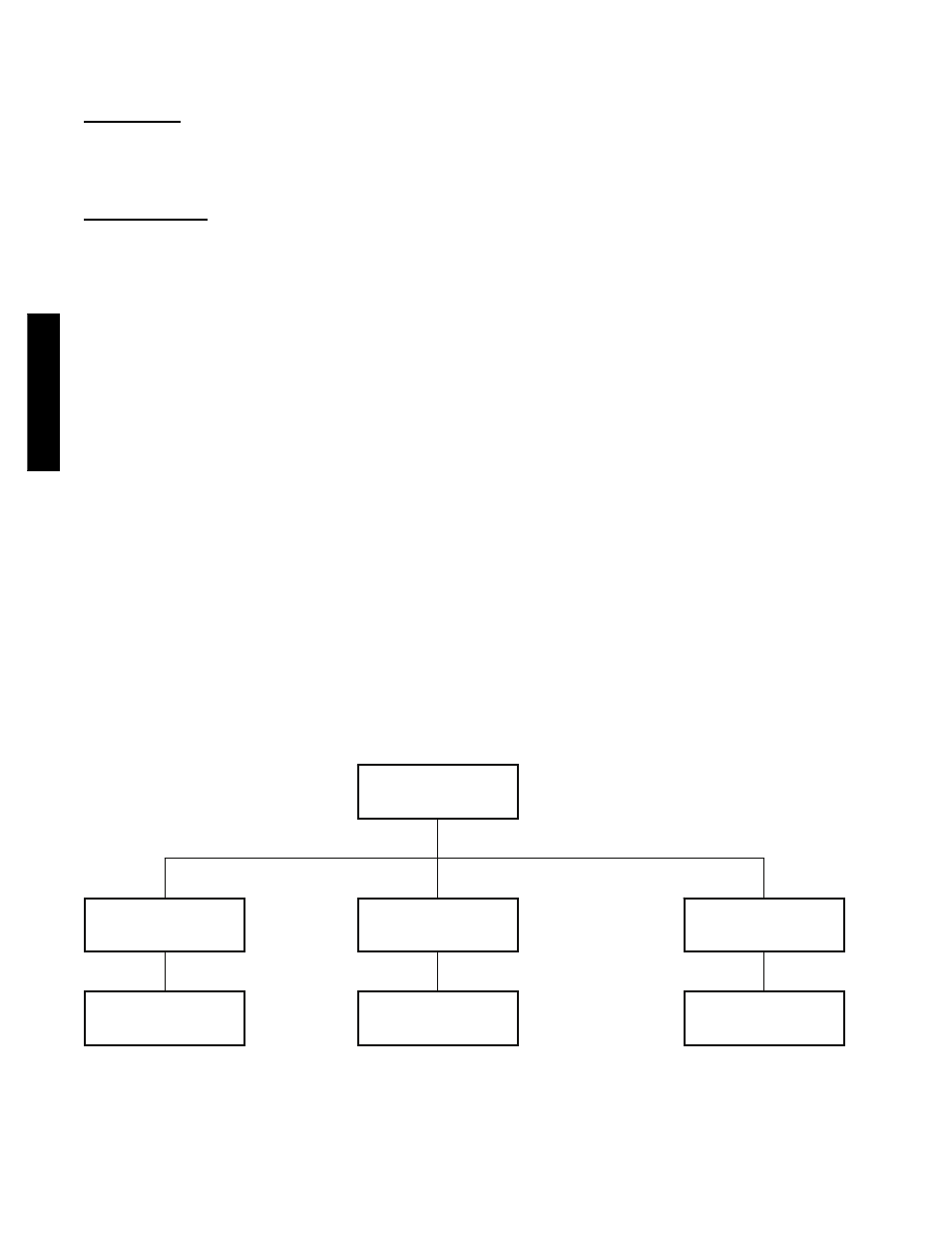

Unit has a problem

Unit displays a

diagnostic code

Unit not running and

no diagnostic code

Unit running but not

optimally

Refer to page --- , identify

error code and use

appropriate diagnostic chart

Go to chart # 8

Go to chart # 9 &10

Unit has a problem

Unit displays a

diagnostic code

Unit not running and

no diagnostic code

Unit running but not

optimally

Refer to page --- , identify

error code and use

appropriate diagnostic chart

Go to chart # 8

Go to chart # 9 &10

A09359

Fig. 27 – Diagnostic Hierarchy

38/

40GX

C

(Q

)