Crosman BP1764S User Manual

Page 4

ENGLISH

ENGLISH

6

7

9. Removing a Jammed Pellet

A jammed pellet is usually the result of trying to fire the airgun when the pressure is too low. Before firing the airgun make

certain there is sufficient pressure for proper operation, by making sure the gauge needle is pointing to the area between

1000 and 3000 psi.

iN this procedure you Will put a cleaNiNg rod doWN the barrel of a charged airguN. it is extremely

importaNt that While you are doiNg this the airguN be “oN safe”, the bolt remaiNs iN opeN positioN aNd that your fiNger be

kept aWay from the trigger. failure to folloW this WarNiNg may result iN serious iNjury or death.

•Point the airgun in a SAFE DIRECTION.

•Put the airgun “ON SAFE” (see section 2A.)

•Open the bolt by pushing the bolt handle up and

pulling it all the way back until you hear two clicks.

•With the bolt in the rearward position insert a

ramrod of the proper size into the barrel (start at the

muzzle). (fig 8) The barrel could be damaged if the

proper sized cleaning rod is not used.

NOTE: The bolt must be cocked and open for the jammed pellet to clear the breech when it is pushed out by the ram rod.

•Using the ramrod push the pellet into the pellet loading port

(forward of the bolt), remove and discard the pellet. Do not reuse

that pellet.

•Point the airgun in a SAFE DIRECTION, close the action take “OFF

SAFE” and fire.

•Put the airgun “ON SAFE” (see section 2A.)

•If you are not able to unjam your airgun by following this

procedure, take no further action. Crosman Corporation or an

Authorized Service Station will unjam your airgun. (no cost during

the warranty period)

10.

Maintaining Your Airgun

Apply Crosman silicone chamber oil (part number RMCOIL) on the barrel

o-ring every 3 months or 500 shots. Apply with a cotton swab as shown in figure 9.

Apply a moly graphite EP grease to the sliding bolt mechanism every 3 months or 500 shots.

Keep all petroleum-based lubricants away from the fill nipple. They MUST NOT be introduced into the high pressure reservoir.

use of petroleum-based lubricaNts iN this area could result iN aN explosioN resultiNg iN persoN-

al iNjury.

DO NOT MODIFY OR ALTER YOUR AIRGUN. Attempts to modify the airgun in any way inconsistent with this manual may make

your airgun unsafe to use, cause serious injury or death, and will void the warranty.

If you drop your airgun, visually check to see that it works properly before you use it again. If anything seems changed, like a

shorter or weaker trigger pull, this may mean worn out or broken parts. Call Crosman customer service for assistance before

using your airgun again.

do Not attempt to repair the airguN or to disassemble to correct aN over fill or valve lock. parts

caN fly from the airguN at daNgerous speeds WheN it is disassembled While pressurized.

11.

Advanced Tuning Techniques

A. Adjusting the Trigger

The Marauder trigger assembly can be adjusted and customized but unless you are experienced in making such adjustments,

Crosman recommends that these adjustments to factory settings be made only by a qualified gunsmith after reading all

instructions. Adjusting the trigger assembly can result in a light trigger pull, decreased sear engagement that could make

the gun more susceptible to discharge when dropped or jarred, or a non-functioning safety. Make only the adjustments

identified in this manual.

NOTE: these adjustment features are for advanced shooters. Most shooters can use the settings provided during

manufacturing of the gun and should not need to make modifications.

The match grade trigger on your pellet air rifle is a two stage, fully adjustable unit. It has been factory set to an efficient

setting that will suit most hunting and target uses. If you, as the owner, wish to alter the factory settings you should do so

only after reading the following instructions carefully.

•Put the air rifle “ON SAFE”, remove the clip and keep the airgun pointed in a SAFE DIRECTION. Depressurize the airgun

(see section 4)

•Remove the stock screw (Fig 12) (using a 3/16” Allen wrench to separate the stock from the action.

•Do not remove the trigger guard screws as the trigger guard should remain with the stock.

adjustmeNt of trigger screW (b) could iNhibit proper fuNctioN of the safety lever (f). thus, alWays

check for full eNgagemeNt aNd smooth fuNctioN of the safety lever upoN completioN of aNy chaNges to the trigger

screW. if you are Not sure if the safety is eNgagiNg aNd operatiNg properly, take your guN to aN experieNced guNsmith.

adjustmeNt to the trigger assembly could alloW this airguN to fire if dropped or jarred, With or

Without the safety eNgaged.

8

Rod

Pellet

9

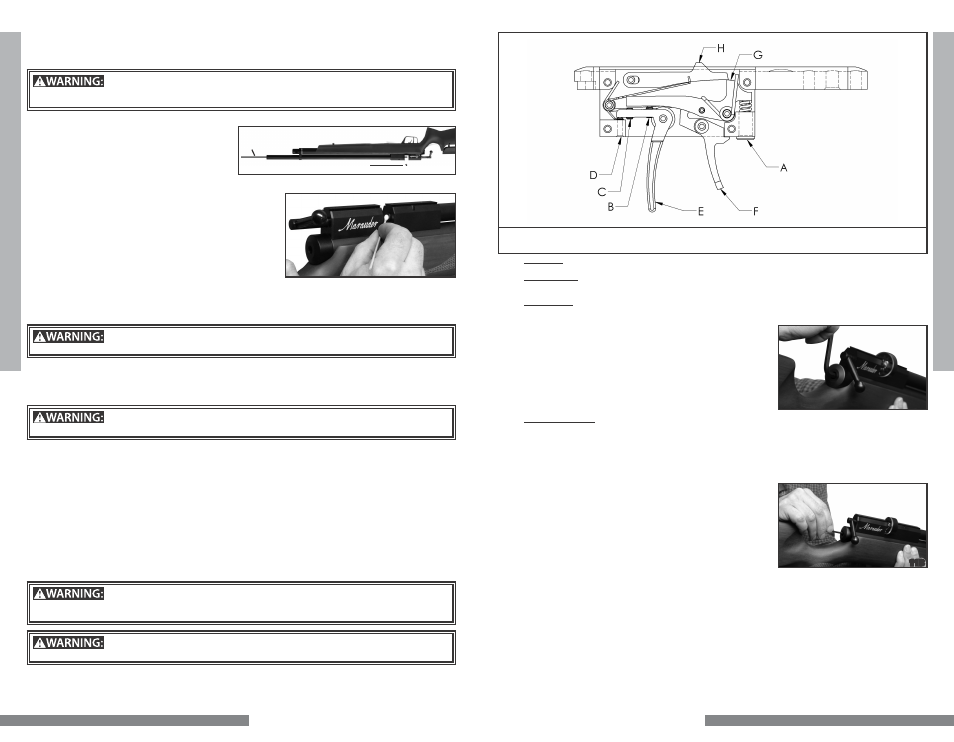

A. TRIGGER WEIGHT ADJUSTER B. FIRST STAGE ADJUSTER C. SECOND STAGE ADJUSTER

D. TRIGGER POSITION E. TRIGGER F. SAFETY LEVER G. LINK H. SEAR

•Trigger Pull Using a 1/8” Allen wrench turn the adjuster screw (A) clockwise to increase trigger pull weight and

counterclockwise to decrease trigger pull weight. This adjustment will not affect sear engagement.

•Trigger Position Using a .050” Allen wrench the trigger position at rest can be adjusted. Turn screw (D) clockwise to

move the trigger back and counter clockwise to move the trigger forward. This adjustment could affect sear engage-

ment, and therefore could allow the gun to fire when dropped or jarred.

•Trigger Stages Using a .050” Allen wrench for adjustment of screws (B) and (C), changes can be made to the position

and length of first and second stages of the trigger motion. These adjustments could affect sear engagement, and

therefore could allow the gun to fire when dropped or jarred.

•Screw (B) changes the first stage. Turning screw (B) clockwise will

increase the length of the first stage and decrease the sear engage-

ment. Turning counter clockwise will decrease the length of the first

stage and increase the sear engagement.

•Screw (C) changes the second stage. Turning screw (C) clockwise

will cause the second stage to occur sooner while turning counter-

clockwise will cause the second stage to occur later.

•Adjustment of screws (B) and (C) should be done in harmony with

each other as they work together to create the trigger’s profile.

Start slowly to understand what each adjustment does and its

relationship to the other.

•Trigger Maintenance The trigger is assembled with a moly graphite EP

grease that should last for years. In the event your trigger becomes contaminated with debris and is not functioning

properly, contact a qualified gunsmith to examine for repair or maintenance.

•After adjusting your trigger, always check that the trigger and safety are functioning properly. If you are not sure if the

trigger or safety is operating properly, take your gun to an experienced gunsmith.

•Re-insert the action into the stock, and replace and tighten the stock screw.

B. Adjusting for Various Fill Pressures

•The Marauder is designed to be tuned to work at various fill pres-

sures from 2000 psi (138 bar) up to 3000 psi (207 bar). This is done by

adjustment of the hammer spring preload and hammer stroke length. In

either case the adjustment changes the amount of energy the hammer

generates when striking the valve. Higher fill pressures require more

hammer energy while lower fill pressures require less hammer energy.

It is advised to always record your settings when tuning your

airgun. (See Page 10)

•The Marauder has been factory set to an efficient fill pressure that will

suit most hunting and target uses. If you, as the owner, wish to alter

the factory settings you should do so only after reading the following

instructions carefully.

•Hammer Spring Pre-load adjuster

•Put the air rifle “ON SAFE” (see section 2A), remove the clip and keep the airgun pointed in a SAFE DIRECTION. Remem-

ber that the airgun is pressurized and make only the adjustments identified in this manual.

•To increase the energy, turn the hammer spring preload adjuster clockwise (fig 11A), up to 6 revolutions, using a ¼”

Allen wrench.

NOTE: More revolutions will simply cause the adjuster to spin but will not yield any higher force. Increasing the preload will

be required to facilitate use of higher fill pressures.

The striker can be accessed through the hammer spring preload adjuster using a 1/8” Allen wrench (fig 11B). Turning the

striker clockwise will shorten the hammer stroke and turning counter clockwise will lengthen the stroke. A long stroke length

will yield higher hammer energy while a short stroke length will yield lower hammer energy. The striker can be adjusted

inward by up to 12 revolutions.

A starting point for low fill pressures would start with a low hammer spring preload tension and a shorter hammer stroke.

A starting point for higher fill pressures will require more hammer spring preload tension and a longer hammer stroke. Refer

to the chart below for suggested combinations of these adjustments based on fill pressures.

11A

Adjusting the

Hammer Spring

11B

Adjusting the Striker

Hammer Spring

Pre-load adjuster

11B