Crosman BP1764S User Manual

Page 3

ENGLISH

ENGLISH

4

5

B. Pressurizing (Filling) the Airgun with a High Pressure Tank

The Marauder may be filled from a high pressure tank (bottle) like the

Benjamin HPB3K. Use the Crosman FAH002 Universal Fill Adapter with this

option. Scuba tanks can also be utilized for the task. For scuba tanks use

the Crosman FAH003 Scuba Yoke Adapter.

•Be sure to wear eye protection

•Make sure the airgun is unloaded and not cocked. (See section 6

for instructions on unloading and un-cocking.)

•Read all instructions with your tank so you are familiar with

its operation.

•Put the airgun “ON SAFE” (see section 2A).

•Point the airgun in a SAFE DIRECTION.

•Remove the cap that covers the fill nipple on the airgun.

•Connect the quick-disconnect fitting on the adaptor’s hose to the fill nipple (fig. 3).

•Slowly open the valve on your tank and start filling the gun SLOWLY. Filling too quickly

will cause heat buildup that can affect accuracy of the fill pressure.

•Watch the gauges on the airgun and your tank (if equipped) until the desired pressure is

reached (2000-3000 psi)

•DO NOT fill the airgun to more than 3000 psi. See “Overfill” information in section 3C.

•Turn the valve on your tank off when the desired fill pressure is reached.

•BLEED the fill hose COMPLETELY to avoid hose whip from pressure in the fill hose

•Disconnect the tank’s fill hose from the fill nipple on the airgun.

•Replace the cap over the fill nipple and tighten. Always keep the fill nipple capped to

eliminate the possibility of dirt entering the check valve.

TIP: If your airgun is being filled from completely empty (zero pressure) the tension of the

hammer pressing against the valve may keep the valve open which will cause air to leak down the barrel. This is most likely

to happen with a gun tuned for a high fill pressures, where the hammer spring preload is adjusted to a high rate. In the event

this occurs try cocking the bolt and leaving it in the rear (fully open) position to eliminate the force on the valve allowing it to

close. Always make certain the airgun is not loaded and there is not a pellet in the chamber.

C. Filling with CO

2

•Refer to instruction manual included in FAH001 or FAH002 Fill Adapters. Read all instructions and warnings included

with the adaptor prior to use.

D. Overfill

•Over filling beyond the “as tuned” best fill pressure does not

improve performance. It will actually lessen performance and may

cause the valve to lock. For instance a gun tuned for best perfor-

mance at 2,000 psi may partially valve lock at 3000 psi. If you dis-

cover that the airgun has been over filled, try to dry fire the airgun

(cock and shoot with no pellet loaded) in a SAFE DIRECTION until

pressure on your airgun drops to 3,000 psi or less depending on

where your gun’s tuned best fill pressure is.

•If the airgun will not discharge air with each shot, the valve

may be completely pressure locked and will require use of the

degassing tool included with your airgun. Follow the instructions

included with the degassing tool to fully or partially depressurize

the airgun.

5. Depressurizing the Airgun

Your Marauder airgun, like most PCP airguns, is best stored with some

pressure in the reservoir. This keeps the seals in the airgun forced against

the sealing surfaces. In the event you want or need to depressurize (e.g.

for service) follow the following steps:

A. Dry Fire Method

•Keep the air rifle pointed in a SAFE DIRECTION.

•Remove all the air from your air rifle by repeatedly cocking and

dry-firing with the air rifle pointed in a SAFE DIRECTION) until the

pressure gauge on your airgun shows no pressure and air cannot

be heard when the shot is fired.

•Put the air gun “ON SAFE”.

B. Degassing Tool Method

Make certain the airgun is not in the cocked position by:

o Pointing the airgun in a SAFE DIRECTION.

o Removing the clip.

o Closing the airgun bolt by sliding forward and latching.

o Pulling the trigger.

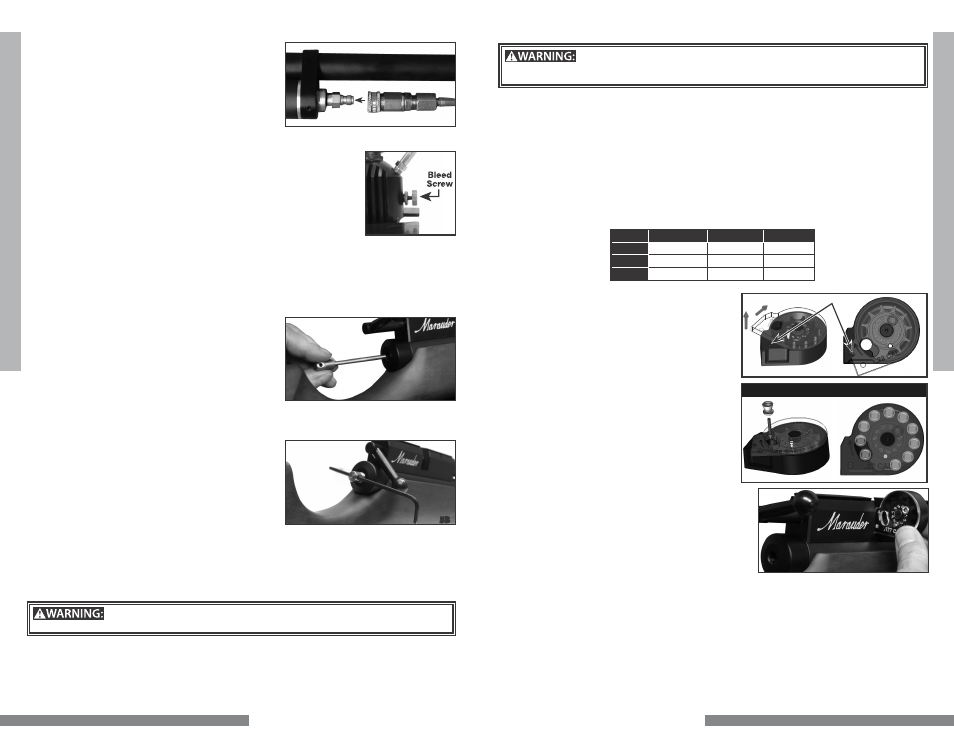

•Insert the degassing tool included with your Marauder airgun into the threaded plug as shown in Figure 5A.

•Turn the tool into the airgun in a clockwise direction until resistance is felt. This will indicate the nose of the tool has

come in contact with the internal valve.

performiNg the folloWiNg procedure Will exhaust air from the barrel at a high rate. make certaiN

the airguN is poiNted iN a safe directioN.

Using an Allen wrench or screwdriver through the hole in the degassing tool (fig 5B) apply leverage to turn the tool and force

the internal valve open. This may require approximately 1-2 complete turns to totally degas the airgun.

•Remove the degassing tool completely from the airgun. Leaving the tool in the airgun will interfere with the normal

operation of the firing mechanism.

•Cock the airgun and dry-fire (no pellet) in a SAFE direction to make certain all pressure has been relieved from

the airgun

•Check the gauge to make certain all pressure has been relieved from the airgun.

3

4

5A

5B

6. Loading the Airgun

use .177 caliber pellets oNly iN your model bp1764, .22 caliber pellets oNly iN your model bp2264, aNd

use .25 caliber pellets oNly iN your model bp2564. Never reuse ammuNitioN. use of aNy other ammuNitioN caN cause iNjury

to you or damage to the airguN.

A. Loading the Clip

•Lift the clear cover over the catch point and rotate in the direction of the arrows (clockwise) per Figure 6A. Turn until

the cover appears as shown in Figure 6B.

•Place a finger under the clip covering the hole, place the first pellet in the clip, nose first (Fig. 6C). Make certain the

pellet does not protrude out the back of the clip. In the event the pellet does protrude simply push the pellet inward.

•Rotate the cover counter clockwise and place the remaining pellets into the clip. Upon completion of filling the

remaining positions rotate the cover until it comes to rest at the catch point as shown in figure 6D. The clip is now

ready for use.

B. Inserting the Clip

NOTE: Following these directions will result in your gun being loaded and ready to fire.

•Put the air rifle “ON SAFE” (see section 2A) and point in a SAFE DIRECTION.

•Pull the bolt back to the cocked position.

•With the cover of the clip facing the butt of the air rifle insert the clip from the right side and push it inward until it

snaps into place. (fig 7)

•Push the bolt forward fully and latch to chamber a pellet.

•The air rifle is now ready to fire.

BP1764

BP2264

BP2564

CLIP #

RC7710

RC2210

RC2508

CALIBER*

.177

.22

.25

CAPACITY

10

10

8

7. Un-Loading and Un-Cocking

A. Unloading- Removing the Clip

•Put the air rifle “ON SAFE” (see section 2A) and point in a

SAFE DIRECTION

•Push the clip out of the receiver from the left side.

•Refill the clip and re-insert for continued shooting.

B. Un-Cocking

In the event you are finished shooting, remove the clip as instructed

and un-cock the air rifle by the following steps:

•Point the air rifle in a SAFE DIRECTION.

•Take the air rifle “OFF SAFE” (section 2B).

•Pull the bolt back to the rear position.

•While firmly holding the bolt in the rear position, pull

the trigger.

•Continue to hold the trigger back while sliding the bolt

forward to the latched position.

•Release the trigger.

•Put the air rifle on “ON SAFE” (see section 2A).

•The air rifle is now ready for storing.

8. Aiming and Firing Safely

•Always point your airgun in a SAFE DIRECTION.

•Follow the instructions for filling the air gun (sections 3A or

3B) and loading pellets (section 5A and 5B).

•You and others with you should always wear shooting glasses

to protect your eyes.

•Do not shoot at hard surfaces or at the surface of water. The pellet

may bounce off or ricochet and hit someone or something you

had not intended to hit.

•Always choose your target carefully. It is best to shoot at paper

bull’s-eye targets which are attached to a safe backstop. A heavy

blanket should be hung behind the backstop to prevent ricochet

should you miss the backstop.

•Your airgun is designed for target shooting and is suited for both

indoor and outdoor use. Always remember to place your target

carefully. THINK about what you will hit if you miss the target.

•Before firing the airgun make certain there is sufficient pressure for proper operation. The gauge needle should be

pointing to the area between 1000 and 3000 psi on the gauge.

6A

6B

catch point

Note: .25 Cal. Clip Holds 8

6C

6D

7