Step 2 — blower motor and wheel maintenance – Carrier 58MTB User Manual

Page 4

4

Table 1 – Furnace Air Filter Table

FURNACE CASING WIDTH

IN (MM)

FILTER QUANTITY AND SIZE *

FILTER TYPE*

SIDE RETURN

*

IN (MM)

BOTTOM RETURN*

IN (MM)

17---1/2 (445)

(1) 16 x 25 x 3/4

(406 x 635 x 19)

(1) 16 x 25 x 3/4

(406 x 635 x 19)

3/4” (19 mm) thick washable

21 (533 )

(1) 16 x 25 x 3/4

(406 x 635 x 19)

(1) 20 x 25 x 3/4

(508 x 635 x 19)

3/4” (19 mm) thick washable

24---1/2 (610)

(1) 16 x 25 x 3/4

(406 x 635 x 19)

(1) 24 x 25 x 3/4

(610 x 635 x 19)

3/4” (19 mm) thick washable

Table 2 – Air Filter Located in Filter Cabinet

FILTER CABINET HEIGHT --- IN (MM)

FILTER SIZE --- IN (MM)

FILTER TYPE

16 (406)

(1) 16 x 25 x 3/4*

(406 x 635 x 19) or

(1) 16 x 25 x 4---5/16

(406 x 635 x 110)

Washable

20 (508)

(1) 20 x 25 x 3/4*

(508 x 635 x 19) or

(1) 20 x 25 x 4---5/16

(508 x 635 x 110)

Washable

24 (610)

(1) 24 x 25 x 3/4*or

(610 x 635 x 19) or

(1) 24 x 25 x 4---5/16

(610 x 635 x 110)

Washable

* Filters with a side return--air may have a different filter size. Measure the filter to obtain the correct size.

Step 2 — Blower Motor and Wheel Maintenance

To ensure long life, economy, and high efficiency, clean

accumulated dirt and grease from blower wheel and motor

annually.

The inducer and blower motors are pre--lubricated and require no

additional lubrication. These motors can be identified by the

absence of oil ports on each end of the motor.

The following items should be performed by a qualified service

technician.

Clean blower motor and wheel as follows:

1. Turn off electrical supply to furnace.

2. Remove main furnace door and blower access panel.

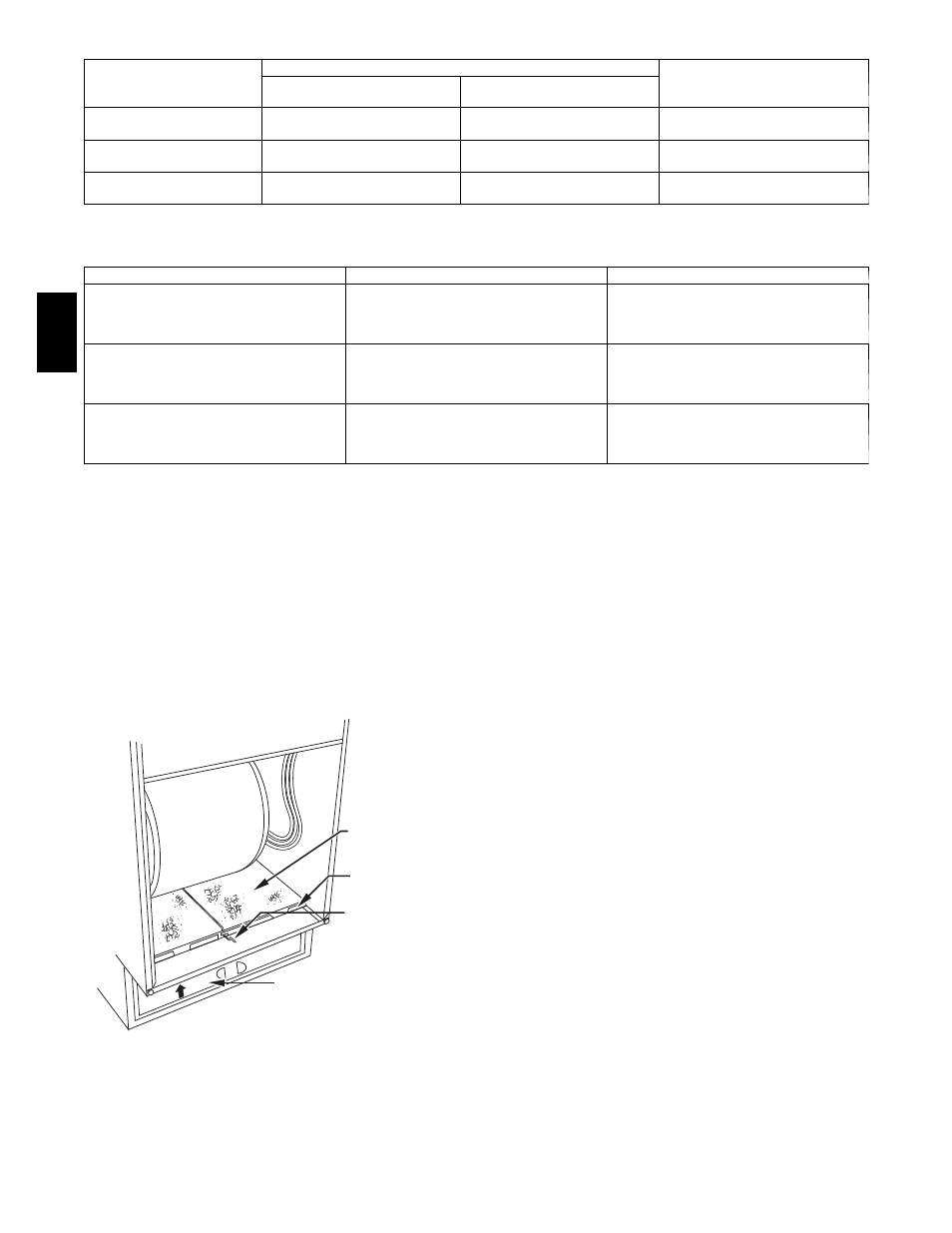

FILTER

FILTER

SUPPORT

FILTER

RETAINER

WASHABLE FILTER OR

DISPOSABLE MEDIA FILTER

IN FILTER CABINET

A08588

Fig. 3 -- Bottom Filter Arrangement

3. Disconnect blower motor wires from furnace control. Field

thermostat connections may need to be disconnected de-

pending on their length and routing.

4. Remove control box mounting screws and position control

box, transformer, and door switch assembly to right side of

furnace casing.

5. If condensate trap is located in left-- or right--hand side of

furnace casing, proceed to item 6, otherwise remove trap

and tubing as described below (See Fig. 5):

a. Disconnect field drain connection from condensate trap.

b. Disconnect drain and relief port tubes from condensate

trap.

c. Remove condensate trap from blower shelf.

6. Remove screws securing blower assembly to blower shelf

and slide blower assembly out of furnace. Detach ground

wire and disconnect blower motor harness plugs from

blower motor.

NOTE: Blower wheel is fragile. Use care.

7. Clean blower wheel and motor by using a vacuum with soft

brush attachment. Be careful not to disturb balance weights

(clips) on blower wheel vanes. Do not bend wheel or blades

as balance will be affected.

8. If greasy residue is present on blower wheel, remove wheel

from the blower housing and wash it with an appropriate

degreaser. To remove wheel:

a. Mark blower wheel location on shaft before disassembly

to ensure proper reassembly.

b. Loosen setscrew holding blower wheel on motor shaft.

NOTE: Mark blower mounting arms and blower housing so each

arm is positioned at the same hole location during reassembly.

c. Mark blower wheel orientation and cutoff plate location

to ensure proper reassembly.

d. Remove screws securing cutoff plate and remove cutoff

plate from housing.

e. Remove bolts holding motor mounts to blower housing

and slide motor and mounts out of housing. Disconnect

capacitor and ground wire attached to blower housing

before removing motor. Motor mounts do not need to

be removed from motor.

f. Remove blower wheel from housing.

58MTB