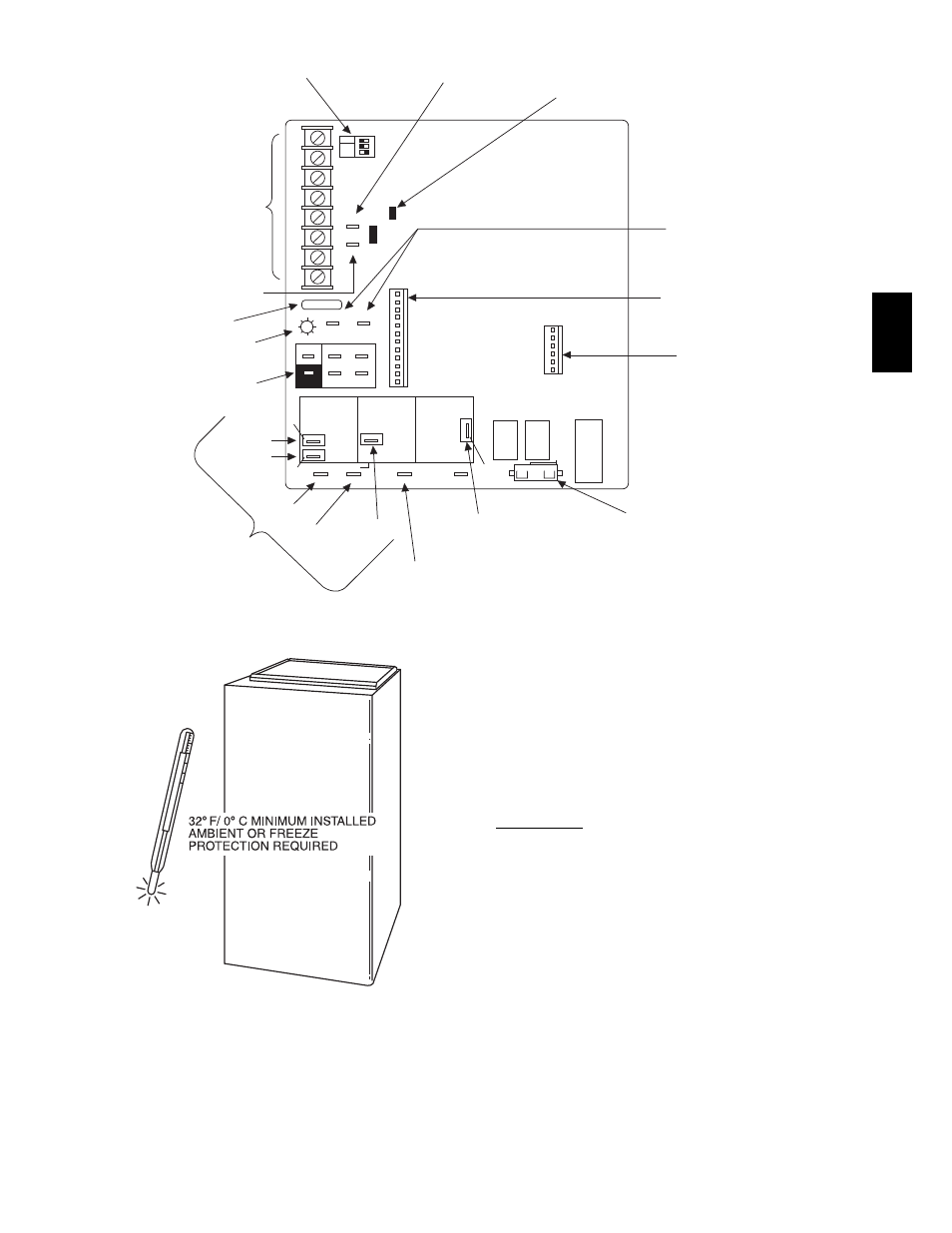

Wiring diagram, Troubleshooting, Two--stage control – Carrier 58MTB User Manual

Page 13: Winterizing the furnace, Status codes, 58mtb

13

LHT

OFF

DLY

ON

OFF

W2

BLW

24-V-THERMOSTAT

TERMINALS

SETUP SWITCHES

LOW-HEAT ONLY AND

BLOWER OFF-DELAY

TWINNING AND/OR

COMPONENT TEST

TERMINAL

ACRDJ - AIR CONDITIONING

RELAY DISABLE JUMPER

TRANSFORMER 24-VAC

CONNECTIONS

PL1 - LOW VOLTAGE MAIN

HARNESS CONNECTOR

PL3

HUMIDIFIER TERMINAL

(24-VAC 0.5 AMP MAX.)

3-AMP FUSE

LED OPERATION &

DIAGNOSTIC LIGHT

115-VAC (L2) NEUTRAL

CONNECTIONS

PL2 - HOT SURFACE

IGNITER & INDUCER

MOTOR CONNECTOR

115-VAC (L1) LINE

VOLTAGE CONNECTION

EAC-1 TERMINAL

(115-VAC 1.0 AMP MAX.)

BLOWER SPEED

SELECTION TERMINALS

HI HEAT

LO HEAT

SPARE-1

SPARE-2 COOL

Y1

DHUM

G

COM

24V

WW1

Y/Y2

R

TEST/TWIN

HUM

1 2 3

PL

T

A

CRDJ

0.5-AMP024 VAC

FUSE 3-AMP

SEC-1

SEC-2

PL1

NEUTRAL-L2

1

EAC-2

BHT/CLR

BHI/LOR

PL3 1

BLWR

COOL

SPARE-1

SPARE-2

1-AMP@115 VAC

EAC-1

PR-1

IDR

HSIR

IDM

IHI/LOR

PL2

1

HSI HI LO

STATU

S

COD

EL

E

D

HI HEA

T

LO HEA

T

L1

A02017

Fig. 17 --

Two--Stage Control

A07911

Fig. 18 --

Winterizing the Furnace

5. Insert funnel in tube and pour up to 1 quart of antifreeze,

propylene glycol (RV, swimming pool antifreeze, or equi-

valent) into funnel until it is visible at point where condens-

ate enters open drain. (See Fig. 19.)

6. Reconnect drain cap to inducer housing.

7. Replace main furnace door.

8. Propylene glycol need not be removed before restarting fur-

nace.

WIRING DIAGRAM

See Fig. 21 for Wiring Diagram.

TROUBLESHOOTING

Use the Troubleshooting Guide, the status code LED on the

control and the Component Test to isolate furnace operation

problems.

Status Codes

For an explanation of status codes, refer to service label located on

back of main furnace door or Fig. 20. The stored status codes will

NOT be erased from the control memory, if 115-or 24-v power is

interrupted. The control will store up to 7 Status Codes.

NOTE: Removing the blower access door will open the blower

access door switch and terminate 115--v power to the control. To

read current status code, remove main furnace door. The status

code LED can be viewed through the sight glass on the blower

access door.

NOTE: NO thermostat signals may be present at control and all

blower off delays must be completed to view previous codes.

To retrieve previous codes, remove one of the red main limit or

flame rollout switch wires 1 to 4 sec until the LED light goes out,

the reconnect it. (Do not leave red wire disconnected for longer

periods of time as the control will assume an overtemperature

condition exists and will respond with blower operation.) This

places the control in the status recall mode and displays the first

code stored in memory.

58MTB