Carl Goldberg GBGA1085 User Manual

Page 5

5

1.

Holding the wing joiner with the angle cut fac-

ing up, insert them into the joiner pockets in

both wing halves. The joiner should fit easily

in the pockets and the wing halves should

meet in the middle, with the wing dihedral form-

ing a broad "V".

2.

Working on a protected surface, and with a

paper towel handy for cleaning fingers,

THOROUGHLY mix 1-2 large (soup) spoons

each from bottle A and bottle B of Epoxy. (Use

equal amount of each part and mix with a stick

in a plastic or paper cup, or on a sheet of

waxed paper.)

Spread epoxy on the joiner on all sides.

Put additional epoxy in the joiner pockets and

in the dowel hole and spread a thin layer of

epoxy along one side of the entire center joint

area. Immediately proceed to the next step.

3.

Working rapidly, so that the epoxy does not

set before you are finished, slide the laminat-

ed wing joiner into one wing pocket.

Place additional tape at several locations

across the center seam of the wing, so that

the halves stay firmly together while the epoxy

sets.

Place a book under the raised wing to help

support it.

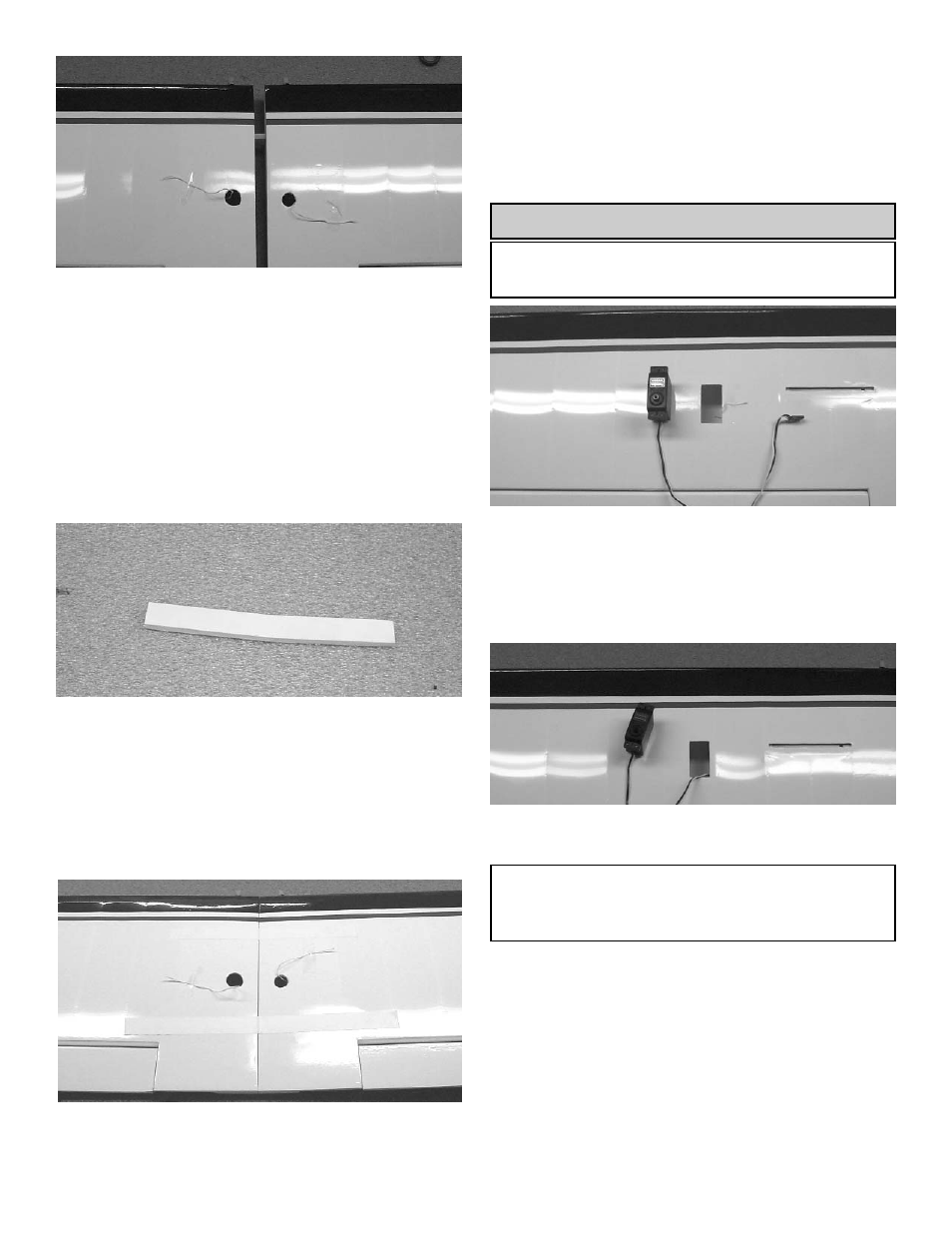

AILERON SERVO INSTALLATION

The following pictures may not exactly match the hard-

ware you are using. Always check the radio manufac-

turer's instructions when installing radio equipment.

1.

Collect the following items:

(1) Wing

(2) Servos with rubber grommets installed

(8) Servo Mounting Screw (supplied with radio)

(2) servo extensions (Might be needed with some

servos)

2.

Plug the

servo extension wire into the servo if

required.

IMPORTANT! To ensure that any connections located

inside the wing will not come loose, when the wires are

pulled, and during flying, always tape them securely

together with electrical tape.

4.

With masking tape, tape the wing halves

together at the trailing edge and close to the

leading edge, as shown. This will help keep

the wing from twisting.