Carl Goldberg GBGA1085 User Manual

Page 11

11

7.

Make sure the stab is level (parallel) with the

wing and insert paper strip shims under the

low side of the stab, if necessary.

Remove the stab & fin from the fuse.

9.

Spread epoxy on both the bottom of the stab,

fin and the fuselage where the fin will rest.

Replace the stab on the platform and the fin

into the slots, after again checking the align-

ment of the stab to the wing, tape together

and allow the epoxy to dry thoroughly.

7.

Re install the stab back onto the fuselage.

Place the metal elevator joiner at the rear of

the stab next to the fuselage.

Make sure the joiner twist easily up and down

and is centered.

10.

As with the installation of the ailerons, insert a

straight pin in the center of 6 CA hinges.

Mix up a small amount of epoxy and insert it

into the hole in the elevator where the wire

elevator joiner fits.

Slide the hinges halfway into the elevator and

then slide the entire assembly into the hinge

slots in the stabilizer making sure the wire

joiner is inserted in the hole and groove .

Make sure the elevator is flush with the end of

the stab. If desired, tape the elevator to the

stab to keep the pieces together.

11.

Keeping the stab and elevator in position,

remove the pins and apply 3 or 4 drops of thin

CA on to each hinge location.

Repeat steps 10 & 11 for the other elevator.

Allow the elevator/stab assembly to dry for at

least 10 minutes before flexing the elevator.

12.

Insert a straight pin in the center of 3 CA

hinges.

Slide the hinges halfway into the rudder and

then slide the entire assembly into the hinge

slots in the fin.

Make sure the rudder is flush with the top of

the fin. If desired, tape the fin to the rudder to

keep the pieces together.

13.

Keeping the fin and rudder in position, remove

the pins and apply 3 or 4 drops of thin CA on

to each hinge location.

Allow the rudder / stab assembly to dry for at

least 10 minutes before flexing the elevator.

Remove the wing from the fuselage.

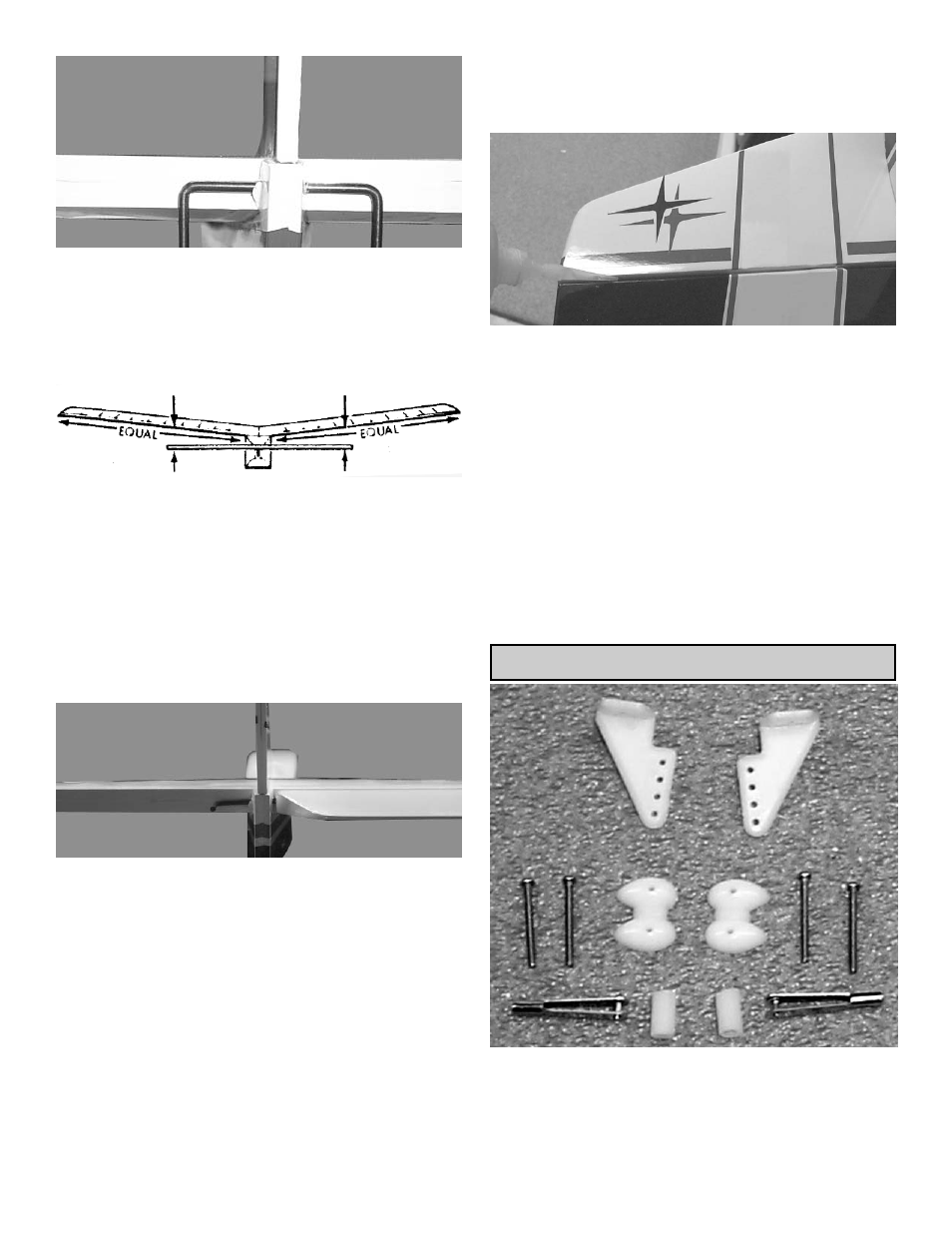

CONTROL HORN INSTALLATION

1.

C

OLLECT THE FOLLOWING PARTS

(2) Nylon Control Horns with Base Plates

(2) 1.5mm x 20mm Machine Screws

(2) 1.5mm Metal Clevis

(2) Silicone Clevis Keepers

(4) Shrink Tubing