Engine installation, Throttle servo – Carl Goldberg GBGA1090 User Manual

Page 10

10

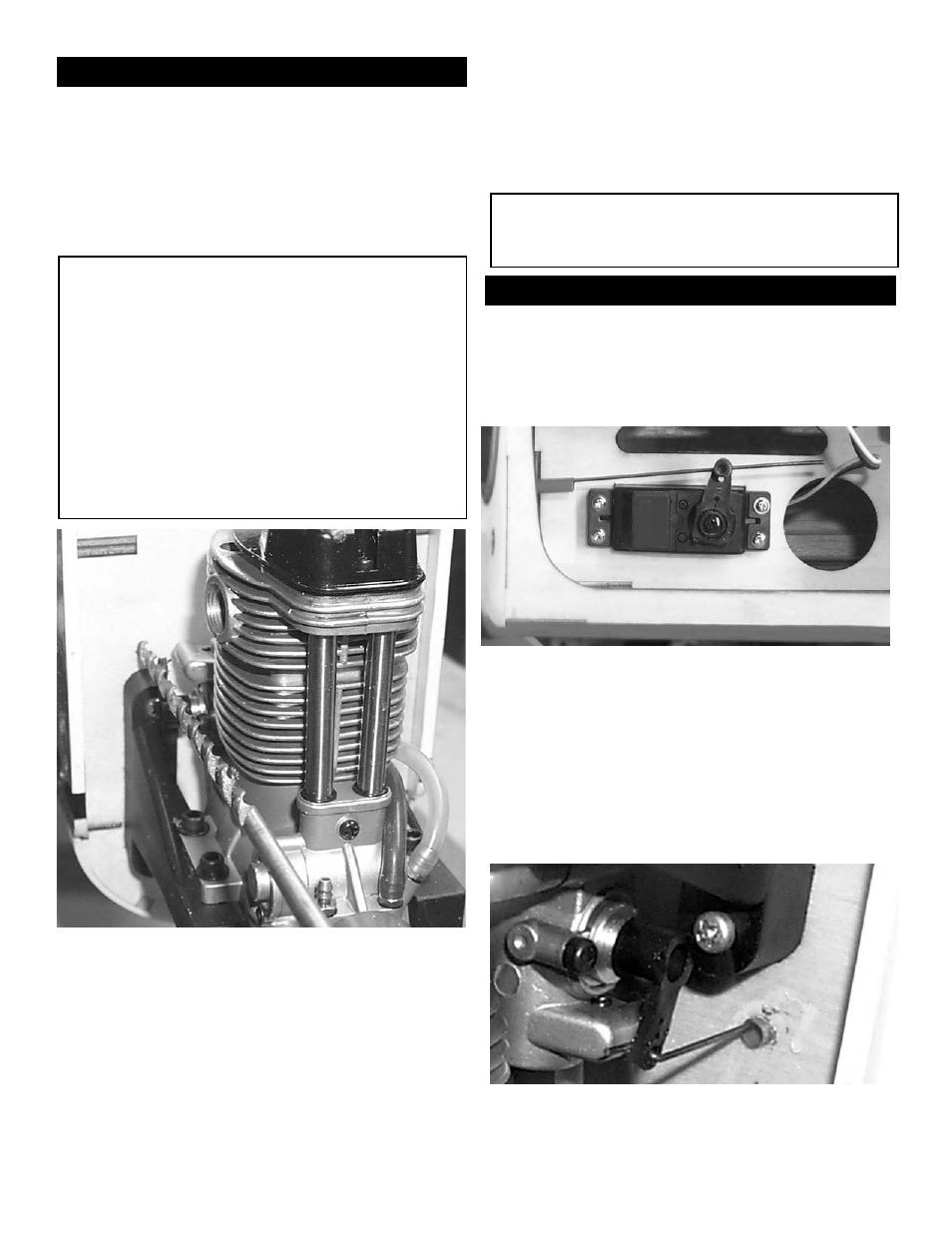

Engine Installation

Collect the following items:

(2) Nylon Motor mounts

(4) 8-32 x 1” Socket Head Screw

(4) #8 Washer

(4) #8 Lock Washer

(4) #6 x 3/4” Socket Head Sheet Metal Screw

Note:

The firewall is pre-drilled for the motor

mounts. the distance between the motor

mount is 1.915, this will work for the OS 120

FS or the YS 140 or any other motor needing

that clearance.

New blind nuts can easily be installed

in the back of the firewall if your choice of

motor does not fit. Measure between the

screw holes to find the vertical center line.

Locate the horizontal centerline by placing a

motor mount on the firewall and marking the

location that the outer line meets the firewall.

1. Install the motor mounts to the firewall using

the 8-32 x 1” socket head screws and the #8

washers. Use thread Lock on the screws

2. Place your engine on the motor mounts so

that the prop drive washer is 5-3/4” from the

firewall.

3. Mark the motor screw locations and drill a

3/32” hole at each location.

4. Screw the motor to the mounts using the #6 x

3/4” socket head screws.

5. Drill a 3/16” hole at the throttle pushrod loca-

tion.

Throttle Servo

Collect the following items:

(1) Throttle Servo with mounting hardware

(1) .062 x 15” Wire

(1) 1/8 x 12” Tubing

1. Install the throttle servo inside the fuselage

using the hardware provided by the radio manu-

facturer.

2. Insert the throttle pushrod tubing through the

firewall and route it back to the throttle servo.

3. Install the EZ connector to the throttle servo

arm. Use Thread Lock

4. Make a bend at one end of the 15” wire.

5. Install the pushrod wire.

Note:

depending on the motor used your pushrod

may not be in the same location as shown.