Carl Goldberg GPMA0960 Gentle Lady User Manual

Page 9

9

11.

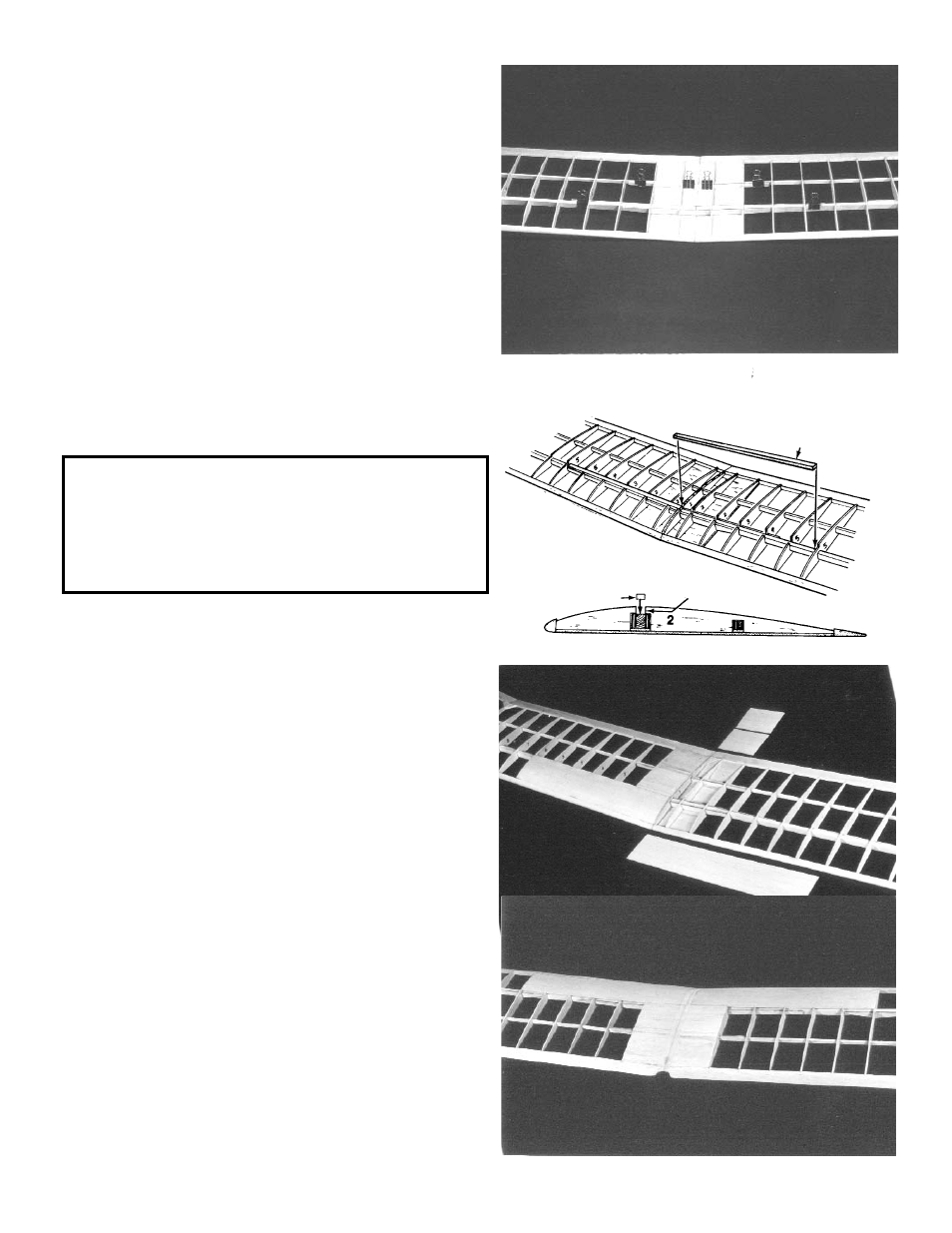

DO NOT USE GLUE YET. Temporarily join wing

panels, using 1/8” ply joiners. Observe and correct fit and

placement of parts for proper dihedral angle. (Each tip

should be about 6-3/8” above the work surface.) Separate

panels and remove joiners.

Now, permanently glue joiners into one side of wing.

Working carefully, apply a slow setting glue, such as

Slow ZAP, to joiners and slide them into position. Clamp

until dry.

Apply glue to joiners, ect., and join both wing halves.

Again check for correct dihedral-each wing tip should be

about 6-3/8” above the table. Clamp joiners and let wing

assembly dry thoroughly.

Glue ribs #2, 3 and 4 to spars and joiners. Turn wing

upside down and glue ribs #3 through #18 to spar

bottoms. Examine entire wing, top and bottom, for any

joints which still need to be glued.

12.

Glue two of rib 1 together to make double thickness rib.

Glue doubled rib 1 at dihedral joint.

Cut L.E. sheeting from 2-1/2” balsa. Glue sheeting

securely to L.E., ribs and center joint.

From 2-1/2” and 3” wide balsa, make remaining sheeting

pieces and glue in place.

13.

Cut and sand a recess in T.E. at dihedral joint for

rubber bands.

Flat sand entire wing smooth.

NOTE: If you’re going to fly a lot in windy weather or use a

powerful winch, you may want to strengthen the wing as follows.

Before adding the sheeting in step 12, notch each rib from the top

down to the spar, on ribs #1,2,2,3, 4 and 5. Glue to the top of the

spar a strip of hard balsa 3/16”x1/4”x10-3/4” (not furnished),and

sand it lightly to match the rib curvature. When the sheeting is

glued in place, glue it also to the 3/16” strip.

Balsa strip

Typical Rib

Notching

From two 3/16”x1/4” strips

(not furnished)

cut 10-3/4” pieces