Carl Goldberg GPMA0960 Gentle Lady User Manual

Page 16

16

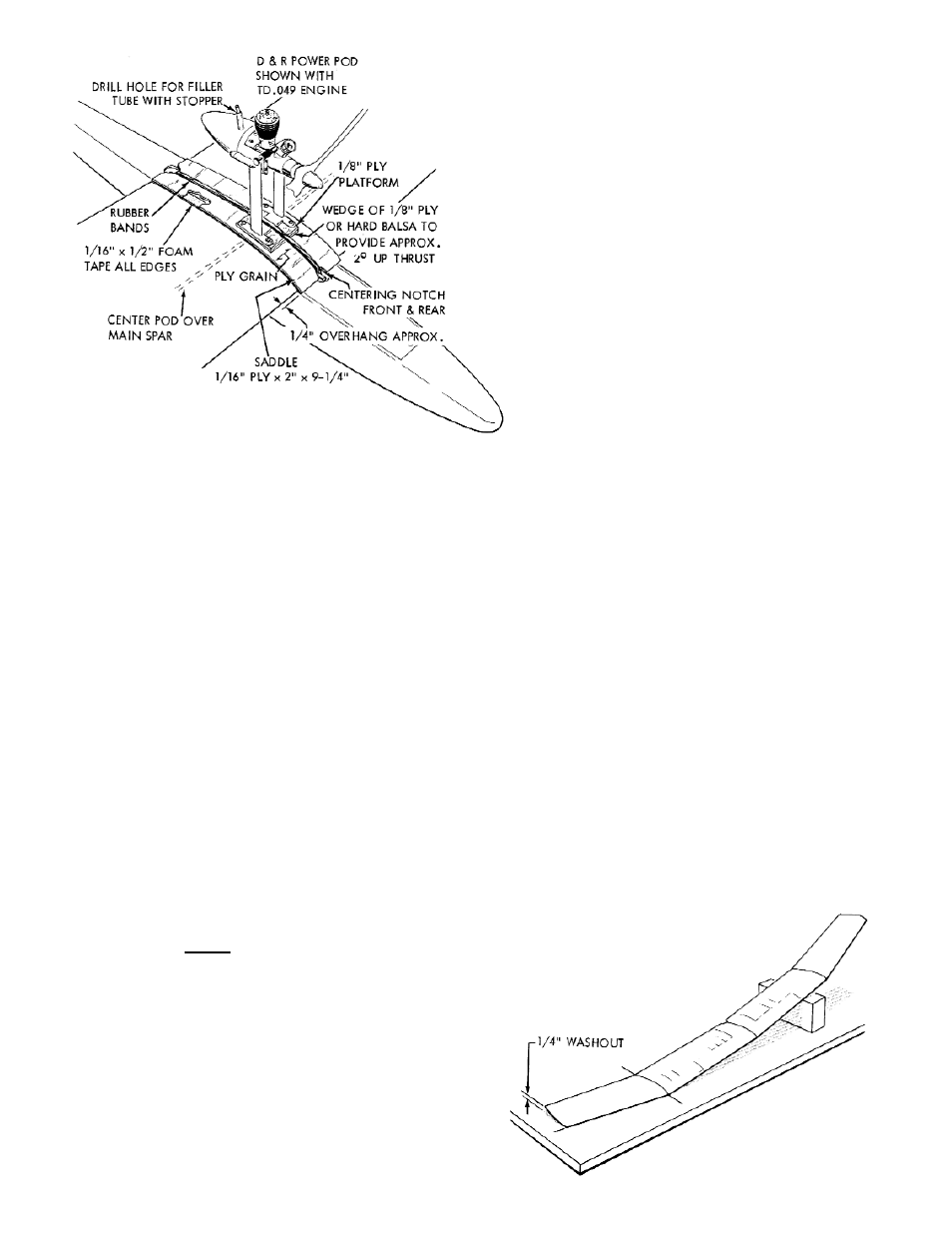

POWER POD OPTION

Make saddle from 1/16” ply x 2” x9-1/4”, grain going the

2” direction. Make center notches front and back for

centering with wing hold down bands. Position 1/16” ply

on wing with an approximately 1/4” overlap at leading

edge, and tape or band to curve of wing. While in this

position, add platform of 1/8” ply x 1-3/8” x1-3/4” with

1/8” ply or hard base wedge underneath front to provide

approximately 2 degrees upthrust. Center platform

directly over main spar and cement to saddle. Drill four

holes in base of power pod and screw to saddle platform.

After fuel-proofing, finish, etc. Add four pieces of

1/16” by 1/2” foam tape on underside of saddle to protect

top of wing surface.

COVERING

A good covering job should be preceded by careful sanding. Filling nicks and dents with MODEL MAGIC™, then more sanding.

Any irregularities in the wood surface will show on the covering, so a smooth sanding job is a must for appearance. A simple color

scheme, such as one main color plus some trim, is recommended for the novice.

COVERING THE WNG

1. First read the directions which are supplied with every roll of

covering. Cut a piece of covering slightly larger than one inboard

panel and remove backing.

2. Position covering on bottom of wing and, using a covering

iron (set at proper temperature), tack covering across center of

wing. Working outward, firmly tack the covering to all ribs, and

to the perimeter edges of the wing, gently smoothing out the larg-

er wrinkles as you go. Besides sticking the film firmly to the end

of the panel, run some of the film down the vertical side of the

rib.

3. After sealing all edges, glide iron (or use a heat gun) over inte-

rior area to tighten the covering. Trim and iron edges.

4. When the bottom of the panel has been completed, repeat the

process on the top side. Follow the same procedure for all wing

panels.

Whenever overlapping one piece of the film on top of another,

make sure you have at least 1/8” of the top firmly stuck to the

one below for the full width of the joint. Otherwise, with little

carelessness in tightening, you can find yourself having devel-

oped an opening to be patched. Where two transparent colors

join, use CGM ColorStripe 1/4” wide to cover joint lines.

TRUING WING AND SETTING WASHOUT

Truing the wing is an important step, and should not be

rushed or omitted. Also, “washout” (explained below)

improves the wing’s efficiency, and increases the glider’s

stability at slow speeds (prevents tip stalls).

1. Set inboard panel on a flat surface to detect warp. To

counter any warp found, twist panel slightly in direction

opposite to the warp, and hold position while gliding iron

over covering to re-tension structure. Repeat process

until panel is true.

2. Follow same procedure with other inboard panel.

3. Check first panel and correct any change caused by truing

second panel.

4. Block up wing as shown so polyhedral break and outboard

panel leading edge are flat on table. As necessary, twist

wing while gliding iron over covering. Repeat process

untill 1/4” washout is achieved

5. Follow same procedure for other outboard panel.