Standard set, Part description, E gl-rhg-im – KEYENCE GL-RHG Series User Manual

Page 2

2

E GL-RHG-IM

Circuit design and wiring

Testing and maintenance

Precautions on regulations and standards

CE Marking

KEYENCE Corporation has confirmed that this product complies with the essential requirements of

the applicable EC Directive, based on the following specifications.

Be sure to consider the following specifications when using this product in a member state of the

European Union.

•

Machinery Directive (2006/42/EC)

The GL-RHG is a safety component as established by the European Union's Machinery Directive

(2006/42/EC) Annex V. The GL-RHG complies with the following EN Standards and has been

certified by TÜV SÜD Product Service GmbH.

•

EN61496-1

Type 4 ESPE

•

EN61496-2

Type 4 AOPD

•

EN50178

•

EN61508, Part 1 to 4

SIL3

•

EN62061

SIL CL3

•

EN ISO13849-1

Category4, PLe

•

EMC Directive (2004/108/EC)

The GL-RHG complies with the following EN Standards

•

EN55011

Class A

•

EN61496-1

Type 4 ESPE

These specifications do not give any guarantee that the end-product with this product incorporated

complies with the essential requirements of the EMC Directive. The manufacturer of the end-

product is solely responsible for the compliance of the end-product itself according to the EMC

Directive.

UL Certificate and North American Regulations

The GL-RHG complies with the following North American and international standards and has

received UL certification and C-UL certification. (CCN: NIPF/NIPF7, File No:E184802)

•

UL61496-1

Type 4 ESPE

•

UL61496-2

Type 4 AOPD

•

UL508

•

UL1998

The GL-RHG also complies with the following North American regulations.

•

FCC Part 15B

Class A Digital Device

•

ICES-003

Class A Digital Apparatus

Type examination based on the Chinese standard GB 4584 "压力机用光电

保护装置技术条件

"

GL-RHG has passed the type examination based on the Chinese standard GB 4584 "压力机用光电

保护装置技术条件"

.

However, if the response time (ON OFF) exceeds 20ms, this product cannot be used as a certified

product. The following two conditions may cause the response time to exceed 20 ms.

•

Using GL-RHG in the optical synchronization system and selecting channel A or B

•

Make series connection of GL-RHG

"Wiring system" (page 3)

"Series connection" (page 3)

"Response time (OSSD)" (page 8)

Type examination for "press machine and shearing machine safety

device"

GL-RHG has passed the "Type examination" based on the Industrial Safety and Health Law, Article

44-2.

Other standards

The GL-RHG has been designed in consideration of the following standards and regulations. For

details regarding the following standards, contact the third-party certification organization, such as

UL or TÜV.

•

EN60204-1

•

EN692

•

EN693

•

OSHA 29 CFR 1910.212

•

OSHA 29 CFR 1910.217

•

ANSI B11.1 - B.11.19

•

ANSI/RIA R15.06 - 1999

•

SEMI S2

•

"Guidelines for Comprehensive Safety Standards of Machinery", July 31, 2007, number

0731001 issued by Ministry of Health, Labor, and Welfare in Japan.

Standard set

•

GL-RHG transmitter x 1

•

GL-RHG receiver x 1

•

Test piece With diameter of 25 mm and length of 200 mm x 1

•

Instruction manual (this document) x 1

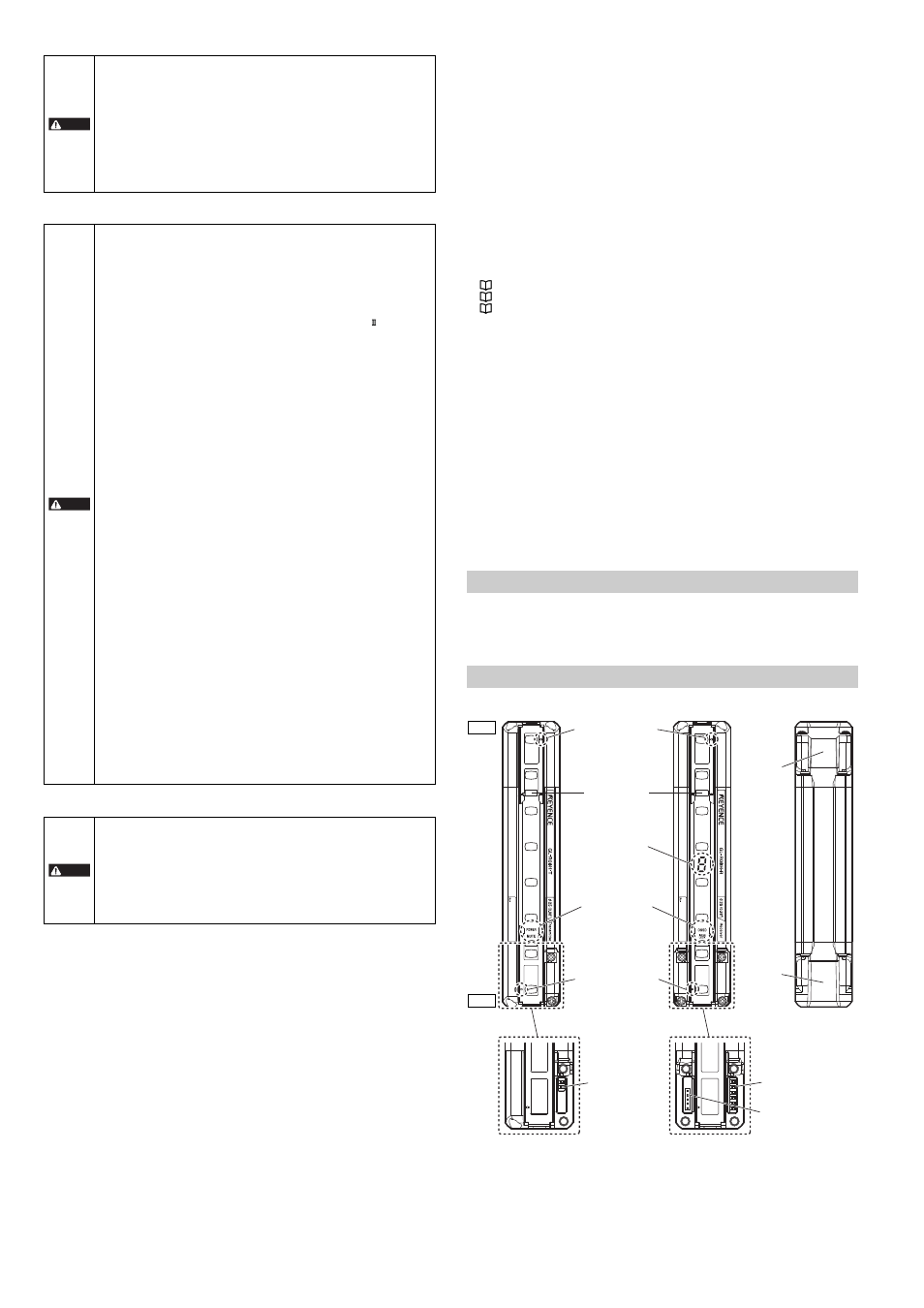

Part Description

* The side where the end cover has already been installed at shipment is the top side.

DANGER

•

The customer is fully responsible for complying with the requirements for muting and/or

override. Those who use muting and/or override must fulfill all of the requirements

related to muting and/or override. KEYENCE accepts NO responsibility and NO liability

for any damage or any injury due to the unauthorized installation, usage or

maintenance, which are not specified in this manual, and/or due to noncompliance with

the laws, rules, regulations and standards in the country or region in which the GL-RHG

is used.

•

Securely tighten mounting brackets and cable connectors used for the installation of

the GL-RHG in accordance with the torque values specified in this manual.

•

When optical synchronization system is applied and Channel A or B is configured, the

response time is longer than the other case. Make sure to accurately calculate the safety

distance according to the response time, and install the GL-RHG at a distance greater

than or equal to the minimum safety distance away from the hazardous zone or hazard.

DANGER

•

Always turn off the power to the GL-RHG when performing electrical wiring.

•

You must fulfill the electrical standards and regulations in the country or region in

which the GL-RHG is being used when you perform the electrical wiring.

•

To avoid the risk of electric shock, do not connect any of the GL-RHG inputs to DC

power sources outside of the range of 24 V DC + 20% or to any AC power source.

•

To avoid the risk of electric shock, be sure that any hazardous voltage is isolated from

all wiring of the GL-RHG with reinforced insulation or double insulation.

•

In order to fulfill the requirements in IEC61496-1, UL61496-1, EN61496-1 and UL508, the

power supply for the GL-RHG must fulfill the conditions listed below.

(a) A rated output voltage of 24 V DC (SELV, Overvoltage Category ) within ±20%.

(b) Double insulation or reinforced insulation between the primary and secondary

circuits.

(c) Output holding time of 20 ms or more.

(d) A power supply must fulfill the requirements of the electrical safety and

electromagnetic compatibility (EMC) regulations or standards in all countries

and/or regions where the GL-RHG is used.

(e) A secondary circuit of power supply (output) must fulfill the requirements for

Class 2 Circuits or Limited Voltage/Current Circuits specified in UL508, if the

GL-RHG is used in the United States or Canada.

•

Do not install the electric wiring of the GL-RHG together with or in parallel with any high-

voltage electrical or power lines.

•

Both OSSD outputs provided on the GL-RHG must be used to establish a safety-related

machine control system. Establishing a safety-related machine control system with just

one of the OSSD outputs cannot stop the machine due to an OSSD output malfunction

and may result in significant harm to the machine operators, including serious injury or

death.

•

When using PNP output type cables, do not cause a short-circuit between the OSSD and

+24V. Otherwise, the OSSDs keep staying at the ON-state and it causes a dangerous

situation.

•

When using PNP output type cables, be sure to connect the load between the OSSD and

0V to avoid a dangerous situation. If the load is incorrectly connected between the

OSSD and +24V, the logic of the OSSD operation will be reversed and the OSSD will

change to an ON state when the GL-RHG detects an interruption in the protective zone.

This is a dangerous situation.

•

When using NPN output type cables, do not cause a short-circuit between the OSSD and

0V. Otherwise, the OSSDs keep staying at the ON-state and it causes a dangerous

situation.

•

When using an NPN output type cable, be sure to connect the load between the OSSD

and +24V to avoid a dangerous situation. If the load is incorrectly connected between

the OSSD and 0V, the logic of the OSSD operation will be reversed and the OSSD will

change to an ON state when the GL-RHG detects the interruption in the protective zone.

This is a dangerous situation.

•

Regardless of whether the cables are PNP or NPN type, you must fulfill the requirements

of Clause 9.4.3 in IEC60204-1: 2005 for protection against maloperation due to earth

fault.

•

All outputs, other than OSSDs, are not allowed to be used as safety outputs for a safety-

related machine control systems. Usage of these functions as safety outputs may result

in significant harm to the machine operators, including serious injury or death.

•

The wait input is not allowed to be connected to the output from any components

comprising a part of the safety-related machine control system. If the wait input is

connected to the output of a safety component it may result in significant harm to the

machine operators, including serious injury or death.

•

The transmitter and receiver cables must be within the lengths specified in this manual.

Usage of cables longer than the specified length may cause the improper operation of

safety functions and may cause a dangerous situation.

DANGER

•

You must always perform the pre-check test in accordance with the checklist, after

maintenance, adjustment or alignment of the target machine or the GL-RHG and before

the machine startup.

•

If the GL-RHG does not operate properly when you perform a pre-check test in

accordance with the checklist specified in this manual, do not operate the machine.

•

You must periodically examine the machine to verify that all brakes, other stop

mechanisms, and control devices operate reliably and correctly in addition to checking

the GL-RHG.

•

The responsible personnel must perform maintenance procedures as specified in this

manual to ensure safety to the machine and GL-RHG.

Transmitter

Beam center-line mark

Receiver

Back side

Center Indicators

7-segment display

Function indicators

Beam center-line mark

Setting switch

(2 switches)

Setting switch

(6 switches)

Connector for the

interface unit

(GL-R1UB)

Top

Bottom

End cover

Connector

for the unit

connection

cable