Checking functions – GEA Bock BCM2000 User Manual

Page 9

9

D

GB

F

E

09794

-05.2012-DGbFEI

Checking functions

Integration of additional switching and control components

• Auxiliary contactor K1.1

An auxiliary contactor K1.1 is provided to protect the contacts in the unit (max. tol. load AC

250 V / 3 A / 750 VA ind.)

• Delay relay K2T

A delay relay K2T 10 - 60 min is to be superposed so that various operating interruptions are

not indicated as fault (adjustment range approx. 10 to 60 minutes, settling time 40 min.)

• Oil sump heating E1

The compressor oil sump heater E1 is to be connected up in combination with the oil tempera-

ture function. The oil sump heater should already be running during the evacuation phase.

If the oil temperature is under +25°C,

the compressor is blocked and the

oil sump heater is running.

For oil temperatures exceeding +25°C, but at the latest after 30 min. pre-heating

time the compressor is released for operation and the oil sump heater switches off.

Checking the functions

General

The unit is mounted in the compressor terminal box. All monitoring sensors are connected and their

functions have been checked. A separate function check is not necessary. The following function

checks can be carried out when spare parts have been supplied or as part of troubleshooting:

Function check for compressed gas/winding/oil temperature

Function check for oil pressure

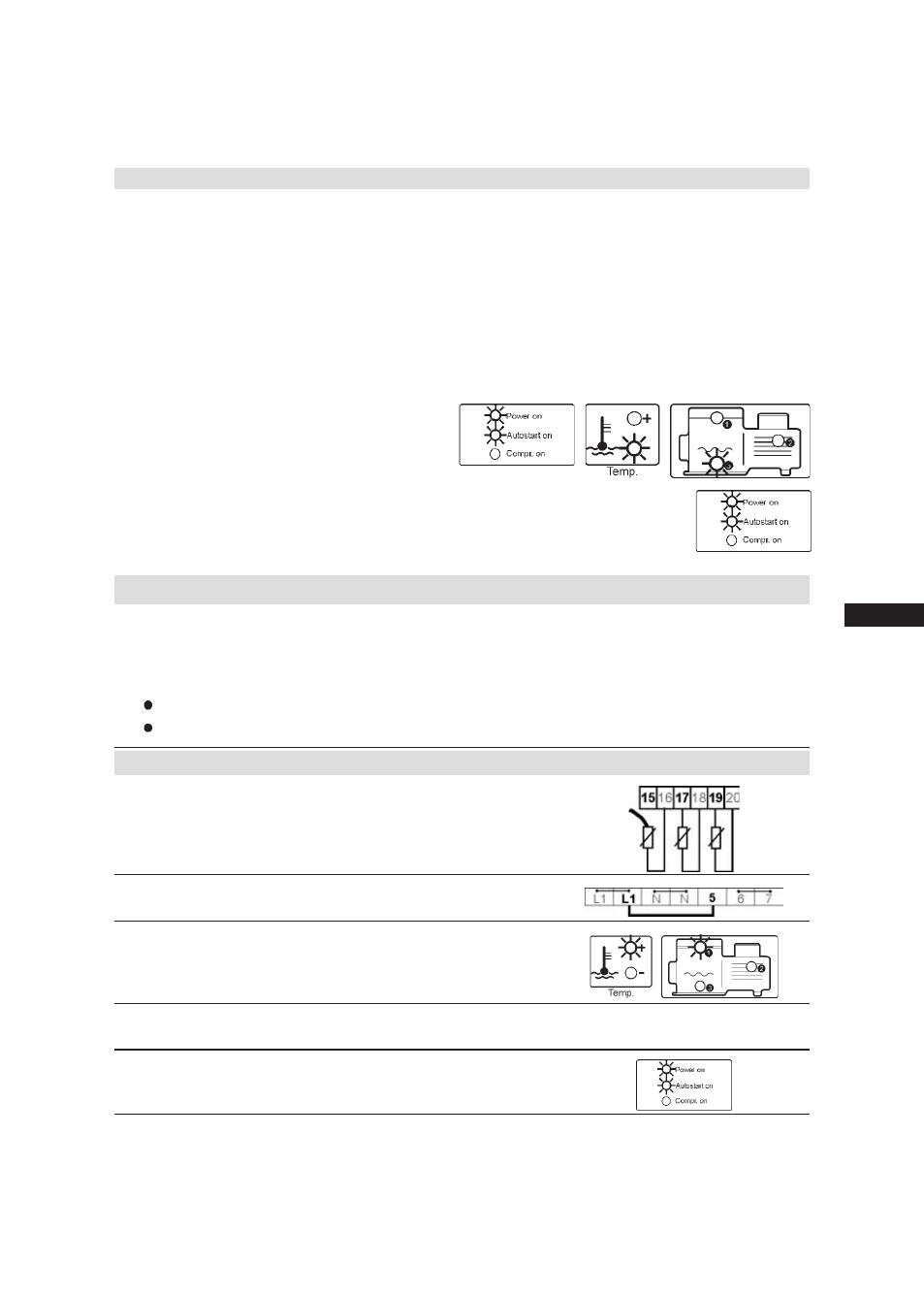

Procedure for checking the compressed gas / winding / oil temperature functions

1 Disconnect from the mains

Disconnect the temperature sensor (terminal 15, 17 or 19)

Important! Every sensor must be checked individually!

2 Insert wire bridge L1 - 5

3 Apply mains voltage

The 2 corresponding LEDs must light up after 30 s delay

4 Disconnect from the mains, remove the wire bridge (see no. 2), connect sensor (see no. 1)

5 Apply mains voltage

Unit ready