Product description, Structure / functions – GEA Bock BCM2000 User Manual

Page 4

4

D

GB

F

E

09794-05.2012-DGbFEI

Product description

Connection voltage: AC 230 V + 10% 50/60 Hz

tol. ambient temperature: -30°C … +60°C

Relay: AC 250 V, 3A, 750 VA ind.

Technical data

Connection terminals:

- on power supply section

up to 1,5 mm²

- on control section

up to 0,25 mm²

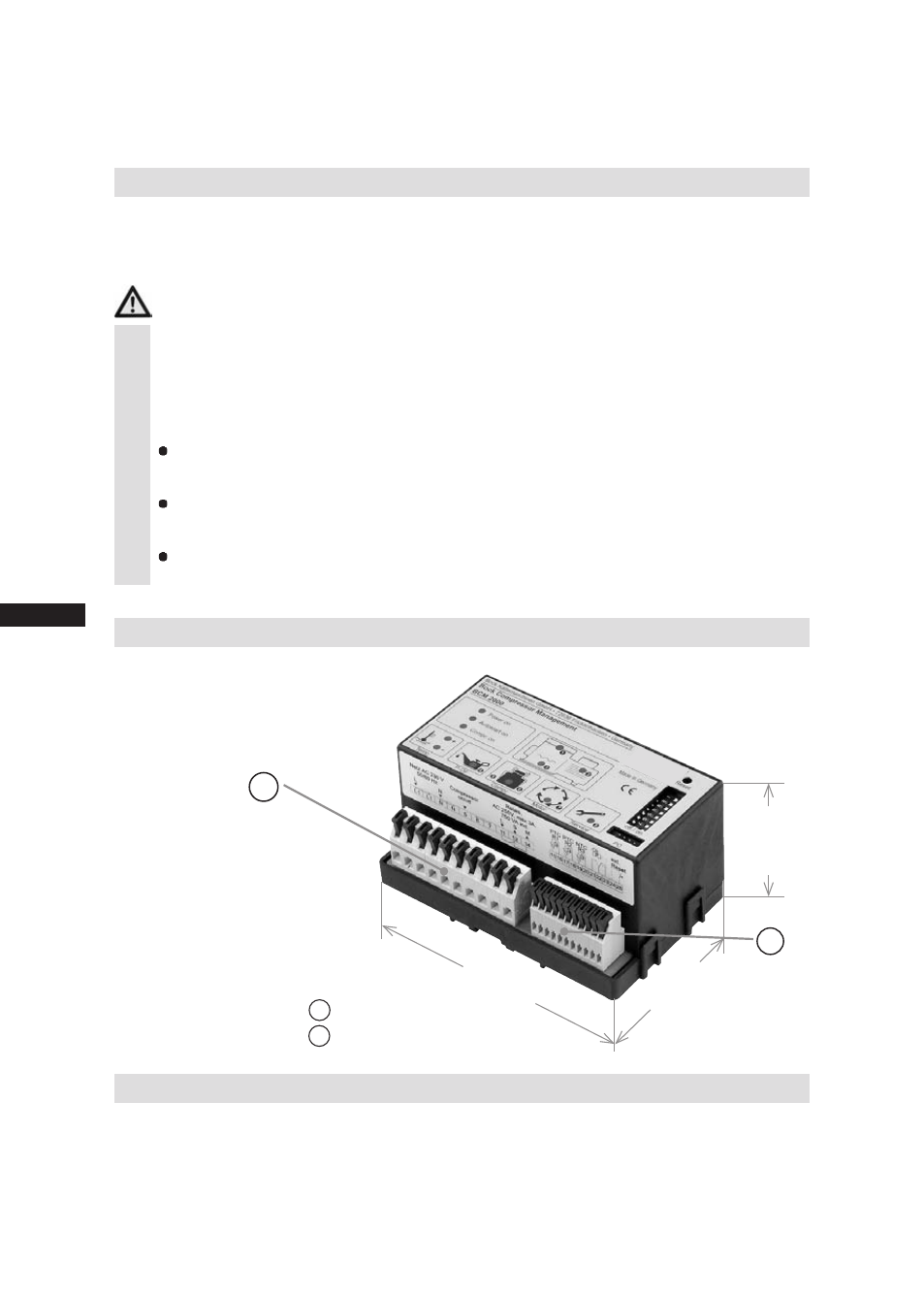

B = 60

L = 100

B

C

H = 52

B

C

Safety

Work on the BCM 2000 may only be carried out by persons whose technical training, skills and

experience together with their knowledge of pertinent regulations means that they are capable of

assessing the work to be carried out and detecting any possible dangers.

Safety instructions

CAUTION HIGH-VOLTAGE CURRENT!

Only qualified electricians are allowed to handle the unit.

The monitoring unit BCM 2000 is mounted in the compressor connection box. Although the

motor connection is covered, the machine must be disconnected from the mains before and

during all work and when testing the machine, otherwise there is a risk of injuries.

National safety regulations, accident prevention regulations, technical rules and other

specifications must be observed.

Compare the voltage and frequency details with the data for the local electricity mains.

The unit may only be connected to the mains when the data coincide.

The terminals of the control unit must not come into contact with the mains voltage,

otherwise the unit and the monitoring sensors will be destroyed.

Structure / functions

The BCM 2000 is used solely for monitoring the operation of BOCK refrigerating compressors. All

monitoring parameters have been coordinated exactly to the compressor connected up in the factory.

Incoming signals are detected as status, information or error messages and processed to release,

shutdown and reporting functions. The unit does not exercise any regulating function.

The unit has three main components:

A - Electronic section B - Power supply section C - Control section

Altogether the unit has 8 monitoring functions: motor winding temperature, compressed gas tempera-

ture, oil temperature, oil pressure, liquid detection during start-up, compressor rotation detection,

surge guard, recommended oil change.

Structure / functions