Troubleshooting, What to do, when – GEA Bock BCM2000 User Manual

Page 15

15

D

GB

F

E

09794

-05.2012-DGbFEI

Troubleshooting

What to do, when ….

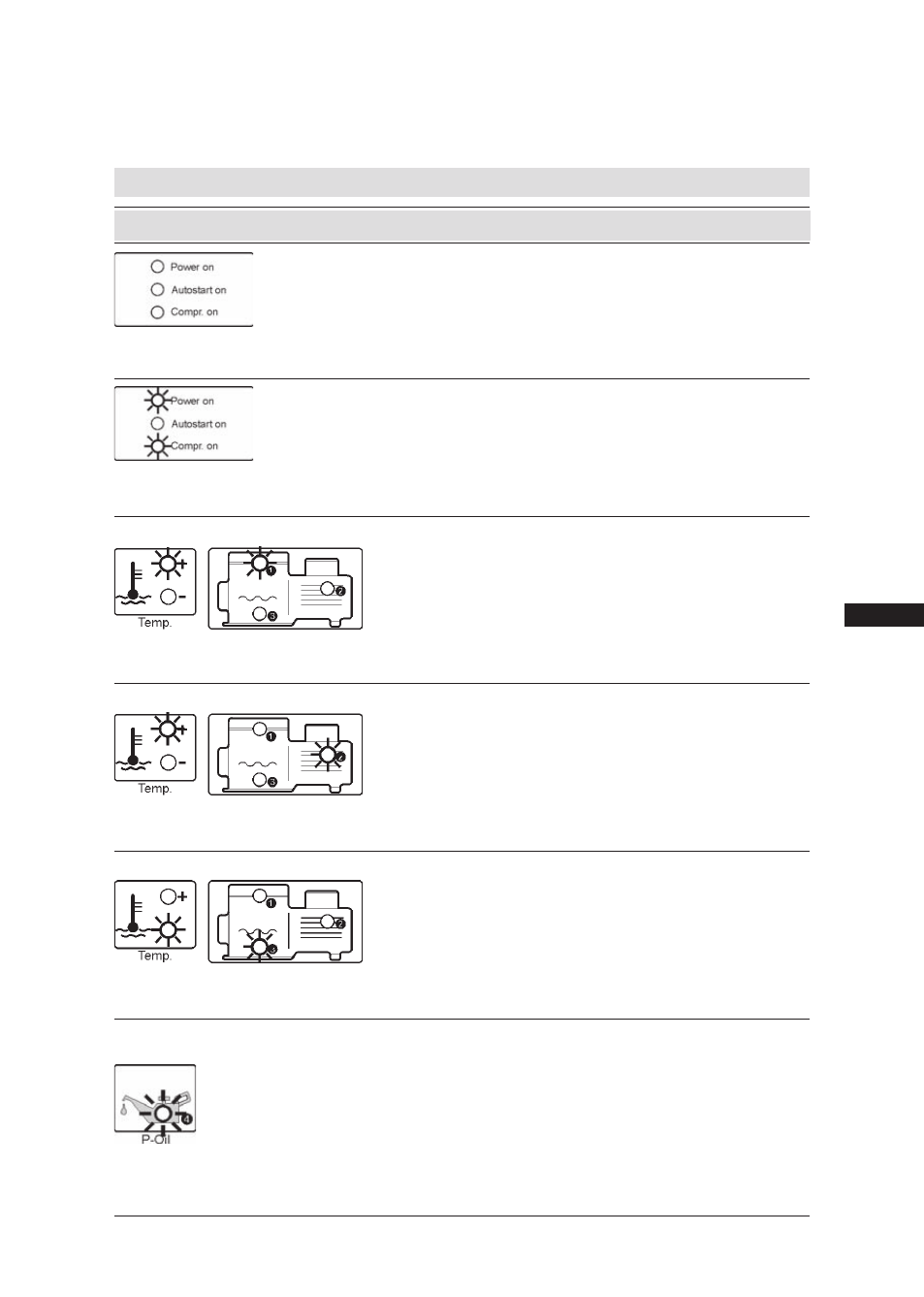

Display

Possible fault causes or information message

> Check control fuse and voltage at terminals

L and N on the BCM 2000

Control voltage is ON

but no LED lights up

> Interruption (open contact) in the safety chain.

Check all integrated switches and units for continuity

LED „power on“ and „compressor on“

light up but the compressor does not turn

Fault message

> discharge end temperature too high

> Suction gas overheating too high

> Condensing temperature too high

> Bypass from pressure to suction side

1 = compressed gas temp. too high

LED ON / Compressor OFF

Fault message

> Motor overload

> Undervoltage

> Control error

> Winding short, short circuit, accidental ground

> Two-phase mode

2 = winding temperature too high

> Motor cooling insuffi cient

LED ON / Compressor OFF

> Extremely unequal phase load

Status message

> Oil sump heating not working

> Pre-heating phase too short

Operation released at +25°C, but at the latest

3 = Oil temperature too low

after 30 min. pre-heating time

LED ON / Compressor OFF

> Oil sensor is not screwed as far as it will go into the Fault

message

screw-in sleeve

> Not enough oil

> Liquid coolant in compressor / in oil

> Dirt in machine / in oil

> Oil pump defect

4 = Oil pressure too low

> Inadequate oil return

LED ON / Compressor OFF

> Unsuitable oil grade

> Damage to bearings or power plant, wear

What to do, when ... ?