Product description, Structure / functions – GEA Bock BCM2000 User Manual

Page 5

5

D

GB

F

E

09794

-05.2012-DGbFEI

Product description

Structure / functions

The BCM 2000 is used solely for monitoring the operation of BOCK refrigerating compressors. All

monitoring parameters have been coordinated exactly to the compressor connected up in the factory.

Incoming signals are detected as status, information or error messages and processed to release,

shutdown and reporting functions. The unit does not exercise any regulating function.

The unit has three main components:

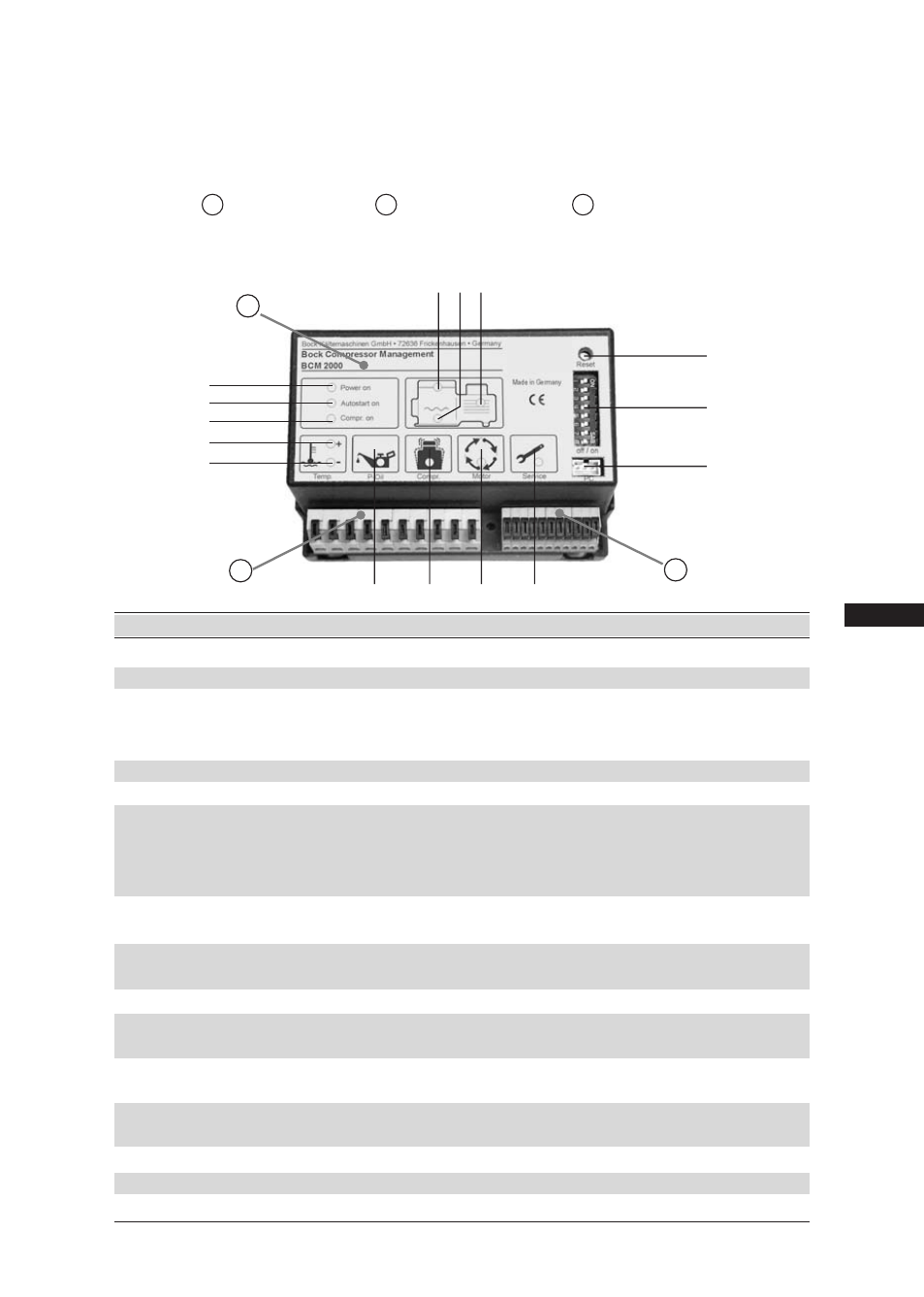

A - Electronic section B - Power supply section C - Control section

Altogether the unit has 8 monitoring functions: motor winding temperature, compressed gas tempera-

ture, oil temperature, oil pressure, liquid detection during start-up, compressor rotation detection,

surge guard, recommended oil change.

A

B

C

12

11

4

9

10

6

5

15

14

13

8

7

2

3

1

Item No. Designation

Function

1

Mains voltage

LED green for mains voltage

2

Compressor operation

LED green for compressor operation

3

Automatic compressor start

LED yellow for automatic compressor release. Com

pressor starts after a delay via the machine

control or lube oil pre-heating

4

Motor winding temperature

LED red

when temperature too high

5

Compressed gas temperature LED red

when temperature too high

6

Oil temperature

LED red

when temperature too low

Compressor is enabled for starting only

when the lube oil is pre-heated to +25°C,

but at the latest after 30 min.

7

Temperature display +

LED red

comb. with item 4 / 5 / 6

8

Temperature display -

temperature too high (+) or too low (-)

9

Oil pressure

LED red

when oil pressure too low

Delay: approx. 90 s

10

Liquid detection

LED red

for liquid hammers during start-up

10

Compressor rotation detection LED red

when compressor does not start although

motor supplied with power

11

Surge guard

LED yellow for more than 12 starts per hour

Compressor continues to operate, no stop

12

Recommended oil change

LED yellow after a certain interval has been exceeded

Compressor continues to operate, no stop

13

Reset button

Reset to operating function

14

Bridging switch

Activates or bridges individual functions

15

PC interface

For reading

}

A

B

C

12

11

4

9

10

6

5

15

14

13

8

7

2

3

1

Item No. Designation

Function

1

Mains voltage

LED green for mains voltage

2

Compressor operation

LED green for compressor operation

3

Automatic compressor start

LED yellow for automatic compressor release. Com

pressor starts after a delay via the machine

control or lube oil pre-heating

4

Motor winding temperature

LED red

when temperature too high

5

Compressed gas temperature LED red

when temperature too high

6

Oil temperature

LED red

when temperature too low

Compressor is enabled for starting only

when the lube oil is pre-heated to +25°C,

but at the latest after 30 min.

7

Temperature display +

LED red

comb. with item 4 / 5 / 6

8

Temperature display -

temperature too high (+) or too low (-)

9

Oil pressure

LED red

when oil pressure too low

Delay: approx. 90 s

10

Liquid detection

LED red

for liquid hammers during start-up

10

Compressor rotation detection LED red

when compressor does not start although

motor supplied with power

11

Surge guard

LED yellow for more than 12 starts per hour

Compressor continues to operate, no stop

12

Recommended oil change

LED yellow after a certain interval has been exceeded

Compressor continues to operate, no stop

13

Reset button

Reset to operating function

14

Bridging switch

Activates or bridges individual functions

15

PC interface

For reading

}