Checkline RH6 User Manual

Page 9

Electromatic Equipment Co., Inc.

-12-

12.0 RESET TO FACTORY CALIBRATION

1. Press the button two times to reach the menu point Options.

2. Select the menu item Reset using the button and confirm by pressing

.

3. Enter the superuser password using the buttons

resp.

and confirm by

pressing .

•

The query “reset?” appears on the display.

4. Press the button for resetting the device to the factory calibration.

•

The software reloads the factory calibration data and reboots the device.

This will need about 15 to 20 seconds.

5. Pressing the button you can exit without any changes.

13.0 CONDITIONING OF THE SENSOR

The conditioning of the sensor (time until the device shows the actual measuring

value) depends on several parameters. The parameter responsible for the highest

measuring error is a temperature discrepancy between the sensors resp. the whole

measuring instrument and the material to measure resp. the air. In order to fasten

the conditioning, the following proceedings are possible:

Spaced insertion of the sword sensor

o

Insert the sword-sensor into the stack for only approx. 10 cm, and push it a few

more centimetres into the stack every 10 seconds.

In case of a high temperature difference repeat this action – if necessary several

times!

o

If you use the sword sensor holder, please ensure that both the sword sensor

and the sword sensor holder are adjusted to the surrounding temperature of the

material.

In this case insert the sword sensor holder at frequent intervals and leave the

sword sensor in the sword sensor holder for an appropriate period.

Electromatic Equipment Co., Inc.

-9-

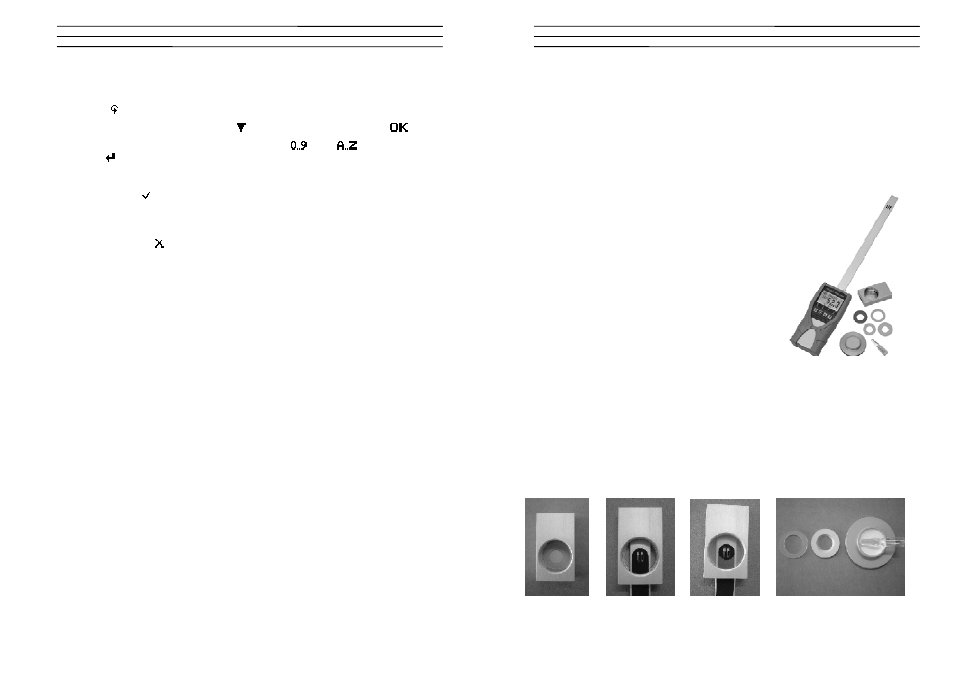

10.0 SINGLE-POINT ADJUSTMENT WITH 50% HUMIDITY STANDARD

For the adjustment the appropriate calibration equipment as well as calibration

ampoules resp. humidity standards of 50 % r.h. are required.

10.1 Proceedings

Preparation

To ensure as good as possible inspection results it is

essential that the measuring device, the calibration

equipment and the calibration ampoules have

approximately

the

same

temperature.

This

temperature has to be between 20°C and 26°C.

The best way to ensure the same temperature of the

different components is to store all components

together in a room with only small temperature

fluctuations minimum over night – better for 24 hours.

Components of calibration equipment

In this image you can see the components of the

calibration equipment and a calibration ampoule with

humidity standard.

10.2 Assembly of calibration equipment

1. Put in the first gasket ring in the upper part of the calibration device.

2. Push in the sword sensor in the upper part as shown in the picture.

3. Now put the second gasket ring into the upper part.

4. Lay in the textile pad in the bottom part of the calibration device, and pour the

humidity standard carefully at the textile pad.