Checkline RH6 User Manual

Page 5

Electromatic Equipment Co., Inc.

-16-

19.0 COMMON REASONS FOR INCORRECT MEASUREMENTS

•

Sunlight or other sources of heat or cold that doesn´t correspond to the

surrounding temperature

•

Dripping or sprayed water

•

Irreversible damage of the sensor due to aggressive gases

•

Danger of condensation because of changing temperature

•

Polluted moisture sensor

•

Foreign objects on the sensor

•

Measuring errors due to too short conditioning

To demonstrate the importance of temperature adjustment, the table below shows

measuring errors due to a temperature difference of only 1°C / 1.8°F between the

measuring instrument and the substance to be measured at different ambient

temperatures.

10°C (50°F) 20°C (68°F) 30°C (86°F)

10%r.h.

±0,7%

±0,6%

±0,6%

50%r.h.

±3,5%

±3,2%

±3,0%

90%r.h.

±6,3%

±5,7%

±5,4%

At room temperature (20°C / 68°F) and assumed paper moisture value of 50% r.h. a

deviation of 1°C / 1.8°F between the measuring sens or and the substance to be

measured results in a measuring error of 3.2% r.h. A deviation of 3°C / 5.4°F would

result in a measuring error of over 10%.

Further examples can be found in the Mollier h-x diagram.

Electromatic Equipment Co., Inc.

-5-

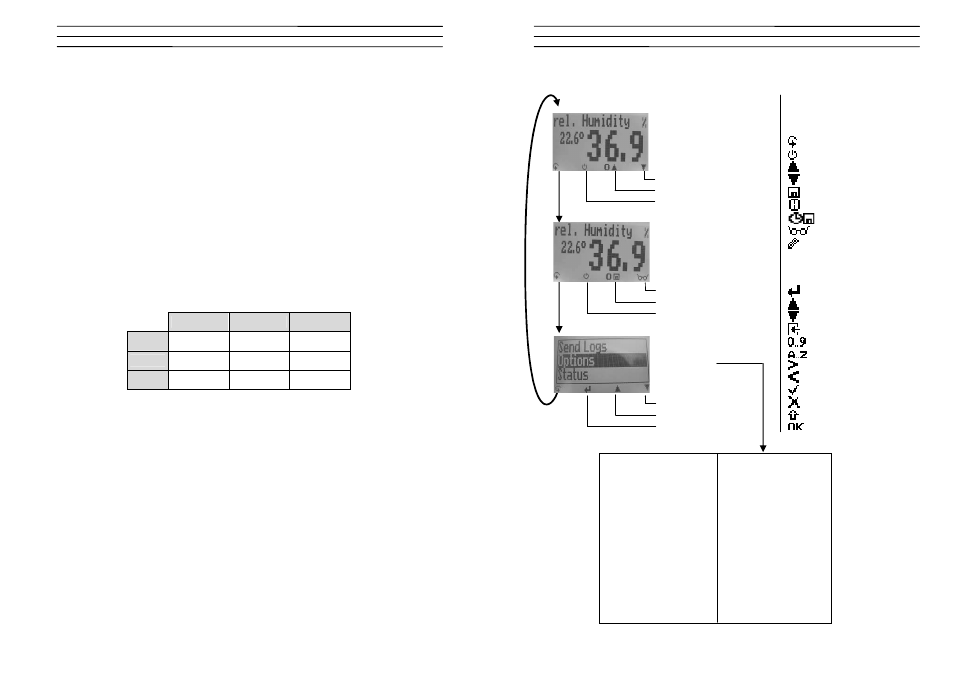

6.0

MENU LEVEL OVERVIEW

Next calibration curve

Previous calibration curve

Power off

Show last log

Store new log

Power off

Type selection menu

Store menu

Main menu

Switch lower

Switch upper

Open this menu / enter

Keypad symbols

Measuring window:

Rolling Menu

Power ON / OFF

Switch upper

Switch lower

Save

Hold

Autolog

Watch saved data

Enter suppliers

data

Menu:

Enter

Switch upper

Switch lower

Exit

Enter numbers

Enter letters

Next or right

Left

Yes

No

Shift

OK

Edit Logs

Manual Logs

Auto Logs

Clear Logs

Print Logs

Last Logs

All Logs

Clear Logs

Send Logs

Manual Logs

Auto Logs

Clear Logs

Options

Date / Time

Datalog Time

Language

Unlock

°C / °F

User level

BL On Time

Auto Off Time

Materialcalib.

Adjust

Password

Reset

Status