Checkline ETMPB User Manual

Page 9

– 9 –

6.0 STORING AND RECALLING TENSION VALUES

The tension meter features a data logger which stores the followng data obtained during

a measuring period:

Average value

Last value

Maximum value (MAX),

Minimum value (MIN),

Minimum peak value (MIN PEAK)

Maximum peak value (MAX PEAK)

NOTE: The measured data remain stored in the ETMB memory even after the

instrument is switched off.

6.1 Storing Tension Values

NOTE: The stored tension values remain stored in the ETMB memory even after the

instrument is switched off.

1. Turn off the tension meter.

2. Insert the process material.

3. Press the MEM key to start the measuring period.

While the tension data are stored, the MEM indicator blinks on the

DISPLAY and the currently measured value is displayed.

When you want to end the measuring period, press the MEM key once again. Data

logging is stopped. The DISPLAY shows MEM and the current reading.

6.2 Recalling Stored Tension Values

1. Be sure that the tension meter is ON.

NOTE: You can end recall at anytime by pressing the POWER key.

2. Press the RECALL key. The display blinks, showing

the average value of the measuring period and the

indicated symbol.

3. Press the RECALL key. The display blinks, showing the

last value of the measuring period (no symbol).

4. Press the RECALL key. The display blinks, showing

the maximum value of the measuring period and the

indicated symbol.

5. Press the RECALL key. The display blinks, showing

the minimum value of the measuring period and the

indicated symbol.

3

D

cN

MEM

22

D

cN

23

D

cN

24

D

cN

21

D

cN

– 12 –

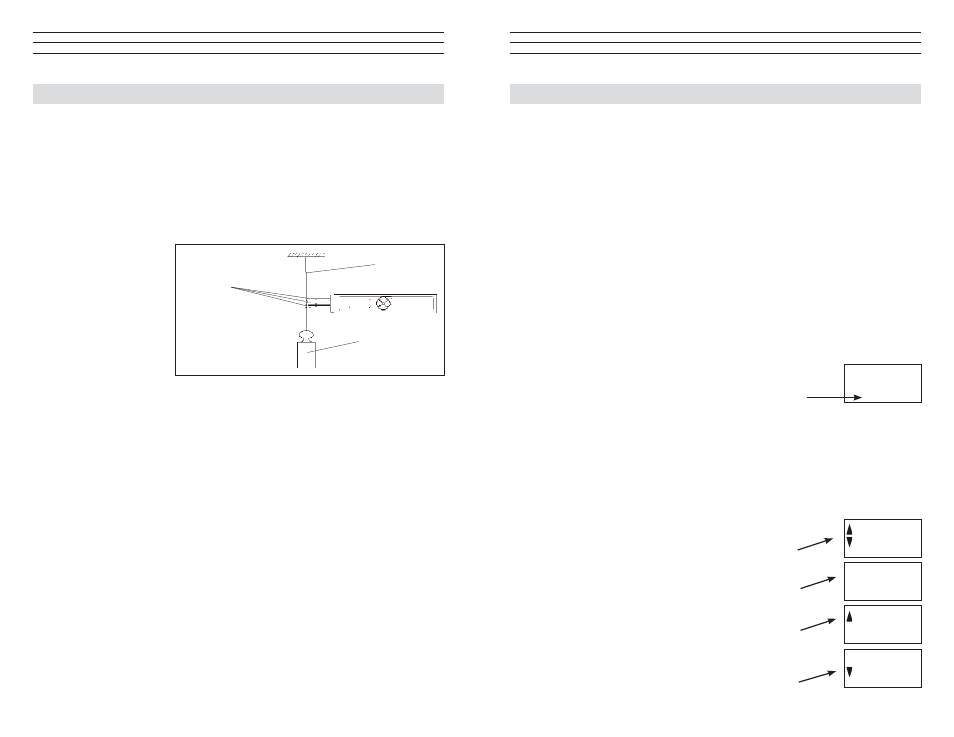

7.0 STATIC VERIFICATION OF MEASURING ACCURACY

All tension meters are calibrated with standard materials—such as polyamide

monoilament (PA)—according to the factory procedure. The diameters are given in

section 1.0. Any difference in process material size and rigidity from the standard

material may cause a deviation of the accuracy.

In 95% of all industrial applications, the factory calibration has been proven to provide

the best results and is used for comparative purposes.

NOTE: Before beginning, make sure that the tension meter is factory calibrated

for a vertical material path. The required reference weight is available.

Veriication procedure:

1. Switch on the tension

meter.

2. Hang a weight

which corresponds

to the tension to be

measured from the

measured material,

vertically, as shown.

NOTE: Pay attention to the correct unit of measure cN or g (gram).

3. Press the LEVER down all the way down and thread the process material through

the MEASURING and GUIDE ROLLERS as described in section 4.1, then

slowly release pressure on the LEVER until the GUIDE ROLLERS return to

their original position.

4. Before verifying the calibration, move the instrument slowly up and down to

compensate for possible mechanical friction losses and thus ensure repeatability of

the measurements.

5. The tension value shown on the Display should be equal to the value of the

suspended weight (pay attention to the measuring units).

If this procedure shows a deviation, you can recalibrate the instrument following the

directions in Sec 8.0

MEASURING- and

GUIDE ROLLERS

Process

material

Weight