E –0 800 – Checkline ETMPB User Manual

Page 8

– 8 –

5.0 DAMPING MODE

The tension meter is equipped with an electronic damping that ensures steady readings

when tension lucutates. This is achieved by averaging the measured values at the preset

update rate.

5.1 Switching On the Damping Mode

NOTE: Before switching on the damping mode, it is recommended that you measure

the irst values without damping enabled.

1. Insert process material as described in section 4.1.

2. Press and hold the DAMP key. The display shows the currently set damping factor.

3. Release the DAMP key. The display shows DAMP below the

currently measured value.

5.2 Switching Off the Damping Mode

1. Press and release the DAMP key. If display shows only the

currently measured value, damping is off.

5.3 Changing the Damping Factor

The tension meter is factory preset to a damping factor of 12. The tension values are

thereby averaged for the display in the following way:

12 old values + 4 new values

16

The damping factor can be modiied in 15 steps from 01 = low damping:

1 old value + 15 new values

16

to 15 = high damping:

15 old values + 1 new value

16

1. Switch on the tension meter

2. Press and hold the DAMP key. The Display shows the set damping factor.

3. You can now increase the damping factor by pressing the MEM key and

decrease it by pressing the RECALL key.

4. Release the DAMP key to return to the measuring mode.

NOTE: The selected damping factor remains stored in memory even

after the gauge is turned off.

22.1

D cN

22.1

D

cN

– 13 –

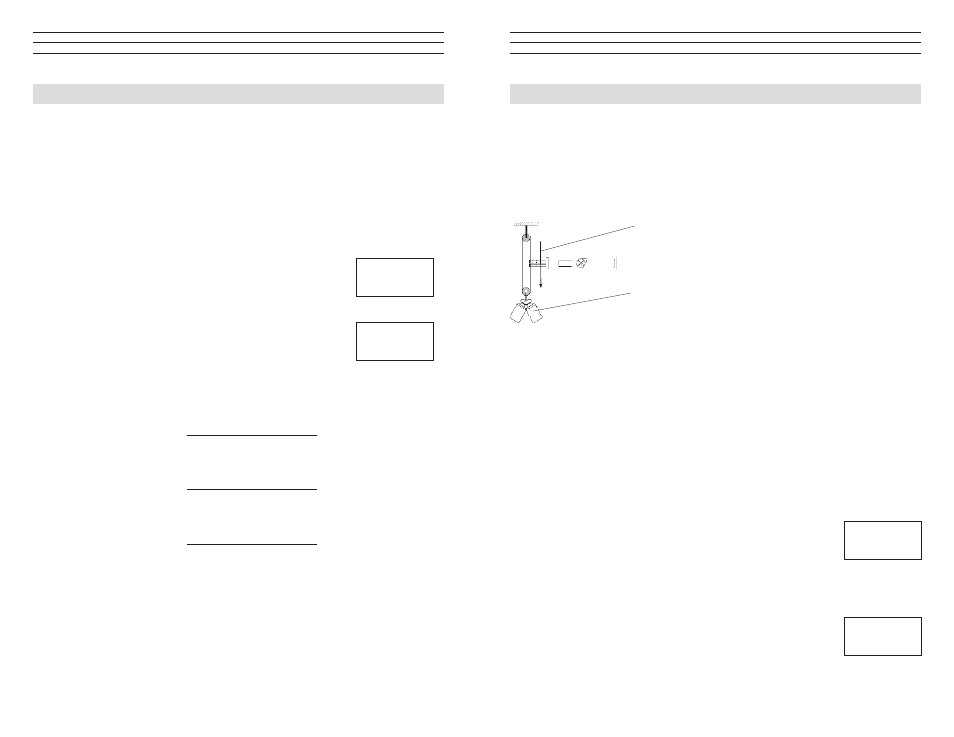

8.0 CALIBRATION

8.1 Dynamic Calibration of the ETX

All tension meters are calibrated with standard materials—such as polyamide

monoilament (PA)—ccording to the factory procedure. The diameters are given in

section 1.0. In 95% of all industrial applications, the factory calibration has been proven

to provide the best results and is used for comparative purposes. The basic setup for a

dynamic calibration is shown below.

Line speed Vmax. = ETMB 100 m/min

Vmax. = ETMPB 60 m/min

Hang twice the weight (pulley effect) which corresponds to

the tension to be measured from the measured material,

vertically, as shown here. Please keep in mind to include

the weight of the lower delection pulley when you calcu-

late the suspended weight. Pay attention to the correct

unit of measure cN.

NOTE: The gauge has been calibrated dynamically according to factory procedure.

Therefore, differences may occur between static and dynamic readings.

8.2 Static Calibration

NOTE: The tension meter is factory calibrated for a vertical material path

Recalibration thus also has to be carried out with a vertical material path.

Before beginning:

Acquire one cN weight each (or several weights adding up to the required value),

corresponding to 10%,40%, 70% and 100% of the tension range. Make sure the tension

meter is switched off and that no process material is inserted between the rollers.

To select the calibration mode:

1. Press and hold the MEM and POWER keys until the Display

shows E –0

2. Release irst the POWER key and then the MEM key.

To calibrate the zero point:

1. Press the RECALL key. As long as the RECALL key is

depressed, the Display shows a random decimal value between

–2000 and 2000, e.g. 800 cN. This decimal value may vary from

instrument to instrument.Write down the decimal value.

NOTE: If the value is outside this range, calibration cannot be guaranteed.

E –0

800