Checkline CAP-TNP User Manual

Page 8

- 8 -

4.0 O

PERATION

4.1 Preparing for testing

1. Determine the size of the sample to be tested.

Adjust the 4-pin jig on the testing table

accordingly.

2. Center the sample and use the knob to secure

the sample in place (turn clockwise to tighten

the jig to the sample material),

NOTE: It is important to make sure that all the

jigs are flush against the moving brackets. Each

jig has set pins which slide into place inside the

grooved brackets.

4.2 Changing Units of Measure

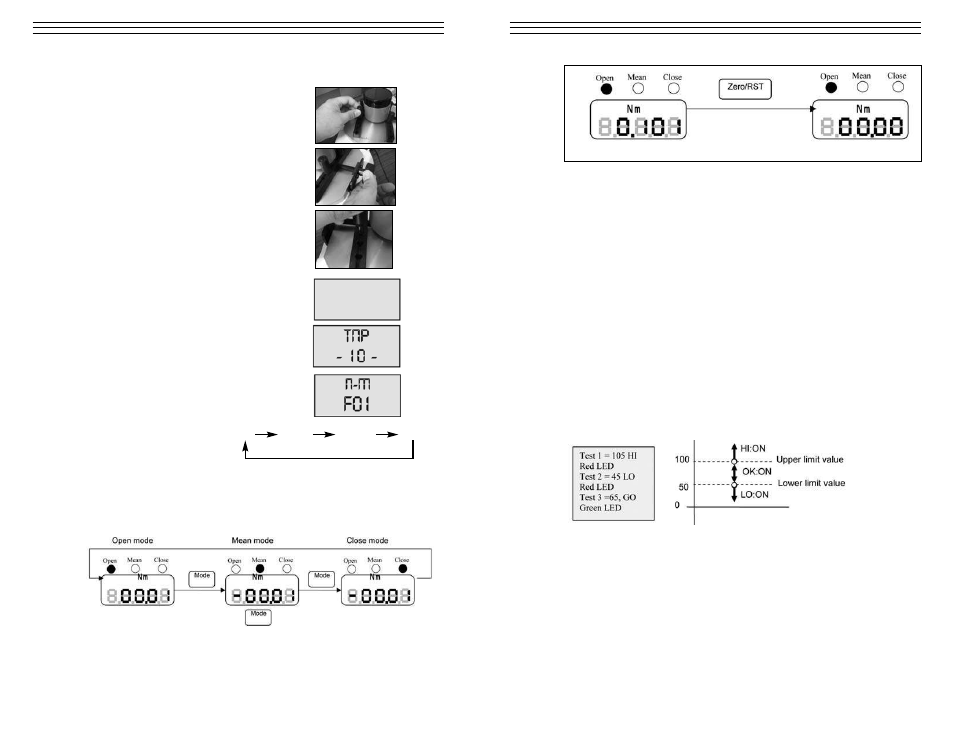

1. Press and hold the Zero/RST key.

The display will appear as shown at right.

2. While still pressing the Zero/RST key, press

and release the POWER key. The display

will change as shown at right.

3. Release the Zero/RST key. The display

will change again as shown at right.

4. Press

MODE to change the measuring unit.

The sequence is as follows: N –m N– cm Kg–Cm Lb –in

5. Press the POWER key to exit.

4.3 Selecting the Measuring Mode

1. Measuring modes available on the CAP-TNP are OPEN, CLOSE, and MEAN.

Pressing the MODE Key toggles through the modes available. Red LEDs

indicate the mode selected. See diagram below.

NOTE: OPEN and CLOSE modes are PEAK Values captured by the CAP-TNP,

these values are not real-time values and are retained on the display until the

Zero/RST key is pressed or a higher peak value is detected (which in this case

replaces the current value detected). MEAN is the real-time value based on the

average data captured at 1000 samples per second.

- 9 -

NOTE: The maximum display update for all modes is 8 times/second. This

update rate can be adjusted by changing F02 from function mode (section 3.2)

Values available are 1, 2, 4, 8 times/second.

4.4 Comparator

Function

This function compares the upper and lower limit based upon the values entered

under function mode for HI and LO limits (section 4.4).

If both HI and LO limits are set to “0000” this feature is not available. The

following conditions are valid under comparator mode:

• HI>LO

• HI=LO (HI Red LED indicator will be lit on the Comparator LED indicators).

This feature makes the CAP-TNP an ideal tool for quality assurance checking.

Example: HI is set to 100 and LO is set to 50. Based from the conditions

met the corresponding LED will light up — HI (Red LED), GO (Green LED),

LO (Red LED).

From the previous example any values greater than 100 will light up the

HI red LED.

Any values lower than 50 will light up the LO red LED.

Values measured in between these values (100

4.5 Setting the HI and LO values

To set the HI and LO limits from the TNP torque meter we need to access the

function mode.

1. Turn off the torque meter.

2. Press and hold the Zero/RST key then turn on the power.

3. Continue to hold on the Zero/RST key until the main display shows F01.

Resetting the Peak Values to zero.