Need photo – Checkline WTTM-GEN1 User Manual

Page 7

– 7 –

6.0 B

ASIC

P

ROCEDURES

6.1 Changing the pull speed (default: 50mm/min)

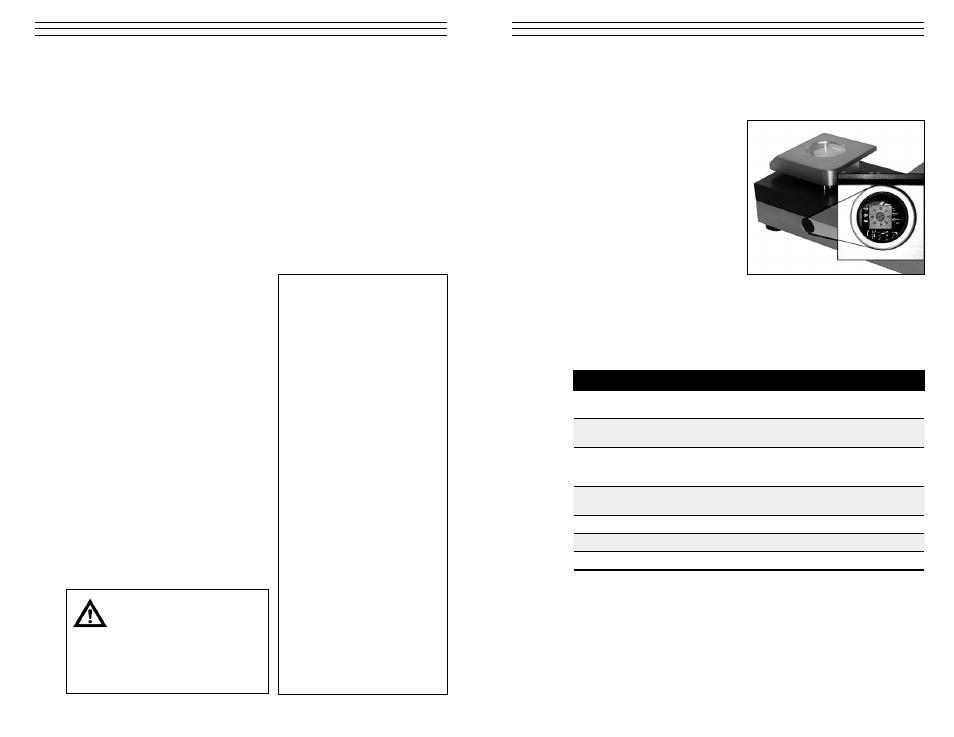

The pull speed can be adjusted

according to the testing standards.

You need a small and a large screw

driver to do this. The selector switch

is protected by a screw thread cap,

in order to avoid an unintentional

manipulation of the pull speed.

To adjust the pull speed:

1. Switch off the instrument and

unplug the power supply.

2. Loosen the protection cap with

the large screw driver

(flat or phillips head?).

3. Adjust the selector switch to the desired pull speed

(How? Using the small

screw driver?)

4. Replace and tighten the protective cap.

Standard

Speed

Switch Position

DIN IEC 60352 Part 2*

25 mm/min

1

UL 486 C

DIN IEC 60352 Part 2

UL 486 C

37.5 mm/min

2

DIN IEC 60352 Part 2

50 mm/min

UL 486 C

SAE AS7928 Table II

3

SAE AS7928 Table II**

100 mm/min

4

SAE/USCAR-21

SAE/USCAR-21

150 mm/min

5

SAE/USCAR-21

200 mm/min

6

SAE/USCAR-21

250 mm/min

7

* DIN IEC 60352 Part 2 replaces DIN 4161/3 ** SAE AS7928 Table II replaces MIL-T-7928

BS5B178 corresponds to IEC 60352 Part 2 UL486A corresponds to IEC 60352 Part 2

– 14 –

10.0 C

ALIBRATION

The WTTM Pull Tester has been calibrated in accordance with factory procedures and

is certified to perform within the stated accuracy specifications shown in the

Specifications section found on page 18. Assuming the unit is handled with care

and operated as detailed in this manual it should remain accurate for an extended

time period. If however, it is subjected to forces that exceed its maximum range or

if it is not properly cared for, it might need to be recalibrated.

It is recommended that the calibration is verified at least on an annual basis and more

frequently if feasible. Normally, instruments of this type go out of tolerance from one

day to the next and rarely on a regular periodic basis.

A calibration procedure is provided in this manual, however it should only be per-

formed by individuals properly trained for this type of service and with the appropriate

certified standards (known weights or secondary force measuring system such as a

load cell, etc.).

Re-Calibration Set-up

1. Remove the lever by unscrewing it in a

counter-clockwise direction and move

the Wire Clamp assembly out from the

path of the hanging sample.

2. Position the WTTM in a vertical

position so that the keypad & display

are at the top (refer to photo). Be sure

to secure it so it can not topple over

when the weight is attached.

3. Using a heavy-duty monofilament

(fishing line), wire or similar, suspend

a 50 Kg weight from one of the teeth

on the wire terminal fixture by hooking

a loop of the material over the selected

tooth.

4. Temporarily, remove the weight and

follow the Re-Calibration Procedures

shown on page 16.

■ Make sure that the

WTTM is well secured

in the vertical position.

Caution

■ Select a material that is strong

enough to support 50 Kg of weight.

need photo