Checkline WTTM-GEN1 User Manual

Page 10

– 10 –

7.0 O

PERATING

P

ROCEDURES

7.1. Switching on the instrument, selecting the measurement unit and

operational mode

1. Switch on the instrument by pressing the

ON/OFF

button.

After a power-up self test and calibration (approx. 20 sec.), the display will

indicate the last selected measuring unit, function and the value 0.00.

2. Select the desired operation mode (indication of the current measurement

value or the peak value) and the measuring unit by pressing the

PEAK

and

MODE

buttons simultaneously. The current settings will be indicated on the

display. When you choose the

PEAK

mode, the peak value will be always

indicated on the display (drag indicator function).

7.2. Resetting to zero before each measurement

It is necessary to zero-set the instrument before starting

each pull force measurement. Press the

RESET

button

for this purpose. The

RESET

button can also be used

for deleting the peak value updated in the memory.

7.3 Taking Measurements

NOTE:

Select the smallest suitable slot for the test

sample diameter.

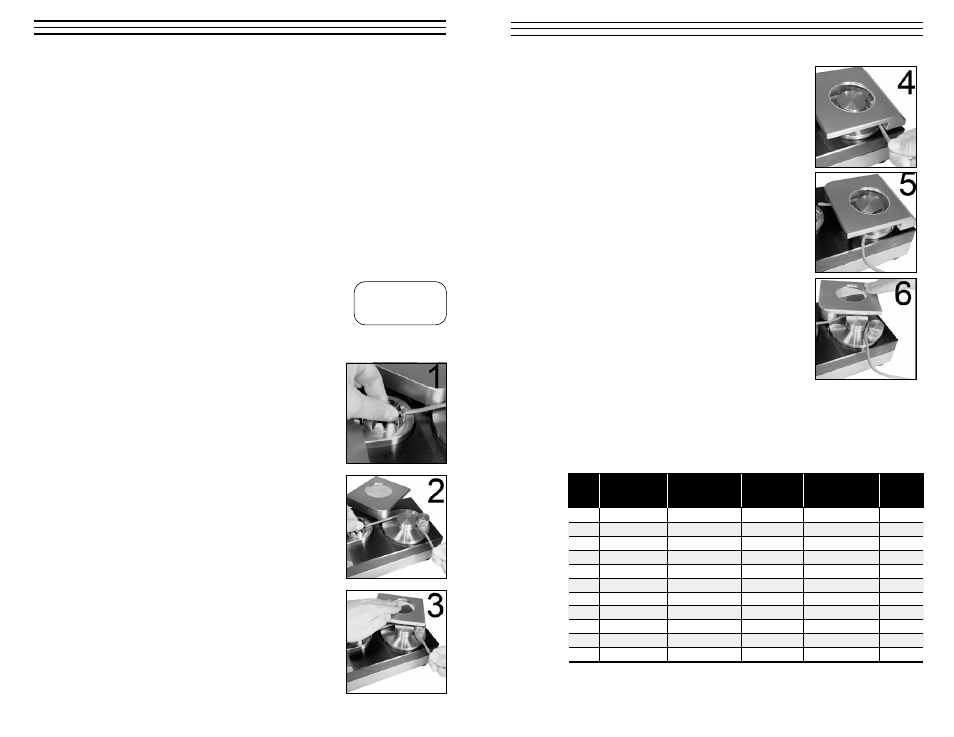

1. Place the cable connection into the adapter, so

that the sleeve of the cable connector stays

securely inside the ring and cannot be pulled out

through the slot.

2. Insert the free cable end with slight tension into

the

clamping fixture

. The nut in the pull force

fixture

will help you to find the right position

for the cable.

3. Holding the cable tight and securely, close the

protection cover.

N

0.0

– 11 –

4. The motor starts and closes the pull force

fixture. Hold the cable end securely until the

pull force develops.

5. The rotational motion of the pull force fixture

tears off the cable from the terminal joint. The

motor stops when the maximal pull length has

been reached.

6. When you open the protection cover, the pull

force fixture returns back to the original

position and releases the cable.

7. During the measurement, the force progression

can be read off the display.

The peak value, which mostly appears before the

connection breaks, is captured at 1000Hz and is

indicated when the

PEAK

button is pressed (so

long as the drag indicator function was not active).

Depending on the wire strength and the related standard, the following

tensile strength should at least be achieved.

AWG

Cross-Section

Cable Diameter

SAE AS7928

IEC 60352 Part2

UL 486 C

Table II

30

0.06 mm_

0.36 mm

6 N

6 N

28

0.09 mm_

0.38 mm

11 N

11 N

26

0.14 mm_

0.48 mm

32 N

18 N

18 N

24

0.22 mm_

0.61 mm

45 N

28 N

28 N

22

0.34 mm_

0.76 mm

67 N

40 N

40 N

20

0.56 mm_

0.97 mm

85 N

60 N

45 N

18

0.93 mm_

1.27 mm

170 N

90 N

45 N

16

1.25 mm_

1.44 mm

223 N

135 N

68 N

14

1.93 mm_

1.80 mm

312 N

200 N

100 N

12

3.16 mm_

2,29 mm

490 N

275 N

138 N

10

4.65 mm_

3.10 mm

355 N

* DIN IEC 60352 Part 2 replaces DIN 4161/3 ** SAE AS7928 Table II replaces MIL-T-7928

BS5B178 corresponds to IEC 60352 Part 2 UL486A corresponds to IEC 60352 Part 2