Brookfield CAP1000 Viscometer User Manual

Page 23

Brookfield Engineering Labs., Inc.

Page 2

Manual No. M02-32A0607

Note: The calibration process may be cancelled at any time prior to pressing RUN by

pressing the ESCAPE key.

When calibration is complete, spindle rotation will stop and the “CALIBRATION COMPLETE”

screen is displayed. (See Figure III-2). Press ENTER to continue.

CALIBRATION COMPLETE

PRESS ENTER TO CONTINUE

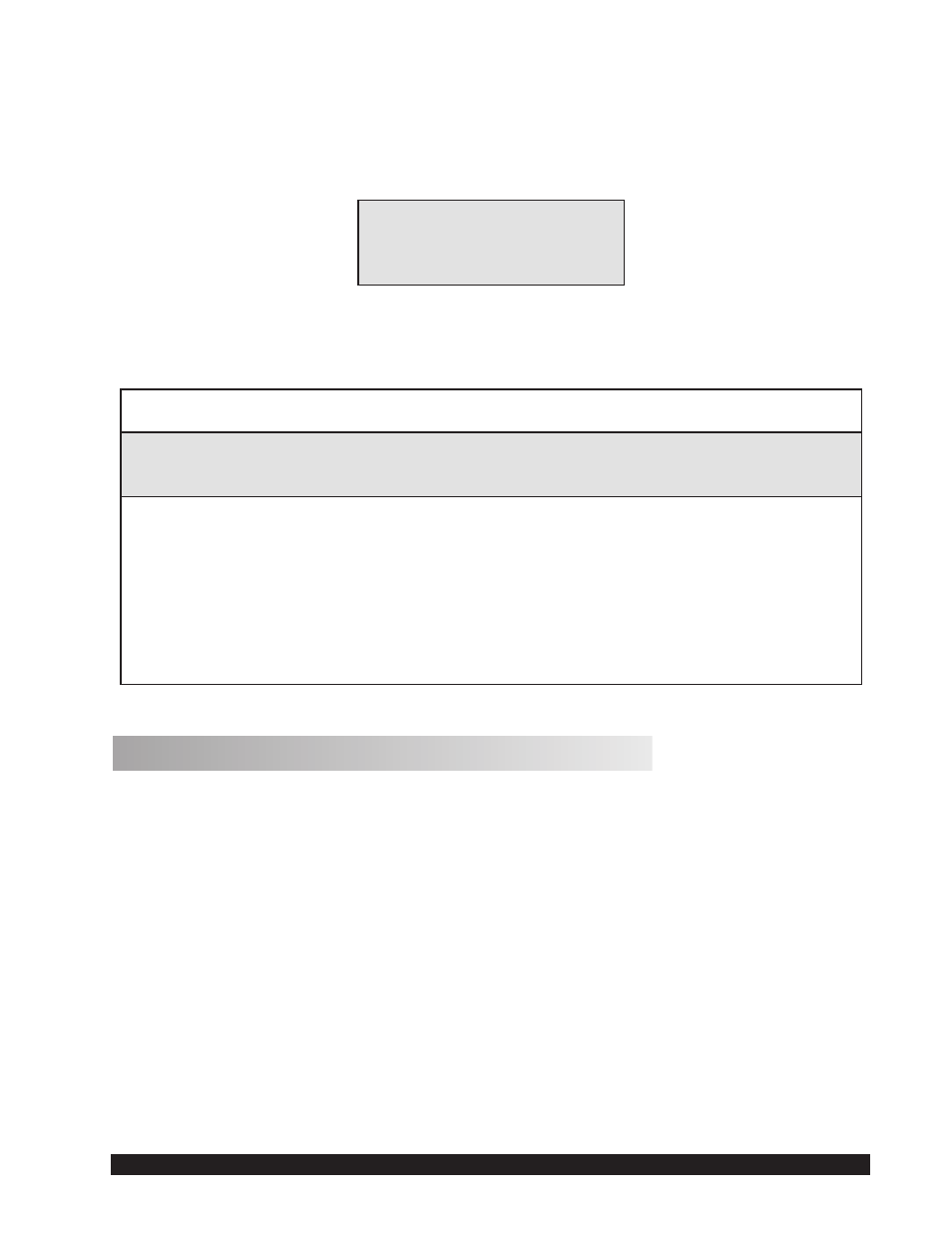

If the viscometer is connected to a printer, the printout (Figure III-3) will automatically be gen-

erated. There will be values for the listed variables. The operator can enter the information by

hand on the botom of the printout.

CONE (00) CALIBRAtION

VIsCOsItY

(POIsE)

FsR

(%)

tEMP

(Deg C)

s.stREss

D/CM

2

)

s.RAtE

(/sec)

sPEED

(RPM)

tIMER

(sEC)

CONE

No.

sAMPLE

No.

Operator: ________________________________________________

Date: ____________________________________________________

Model/Serial #: ____________________________________________

Fluid: ____________________________________________________

Figure III-3

III. Repeatability

The CAP 1000+ Viscometer is repeatable to ±0.5% of the full scale viscosity range (FSR). Due

to shear heating considerations which occur in high shear rate instrumentation, the measurement

of NIST Viscosity Standard Fluids at rotational speeds above 900 RPM will show a decrease

in viscosity with an increase in rotational speed (shear rate).

Normal forces due to the shearing of a viscoelastic fluid (such as paint) are accounted for in

the CAP Series Viscometers by weight on the spindle column of 3.4 Newtons (340,000 Dynes)

total force. This is done to avoid having the cone lift off the plate, thereby changing the cone

plate geometry and producing incorrect viscosity readings. For normal forces greater than

3.4 Newtons (340,000 Dynes) total force, additional externally mounted weights are required.

However, more weight means more wear on the cone and plate. Additional weights should

only be considered when definitely required and removed when not required.

Contact Brookfield Engineering Laboratories or your Brookfield Dealer/Distributor/Representa-

tive for details on the above information.