Brookfield CAP1000 Viscometer User Manual

Page 20

Brookfield Engineering Labs., Inc.

Page

Manual No. M02-32A0607

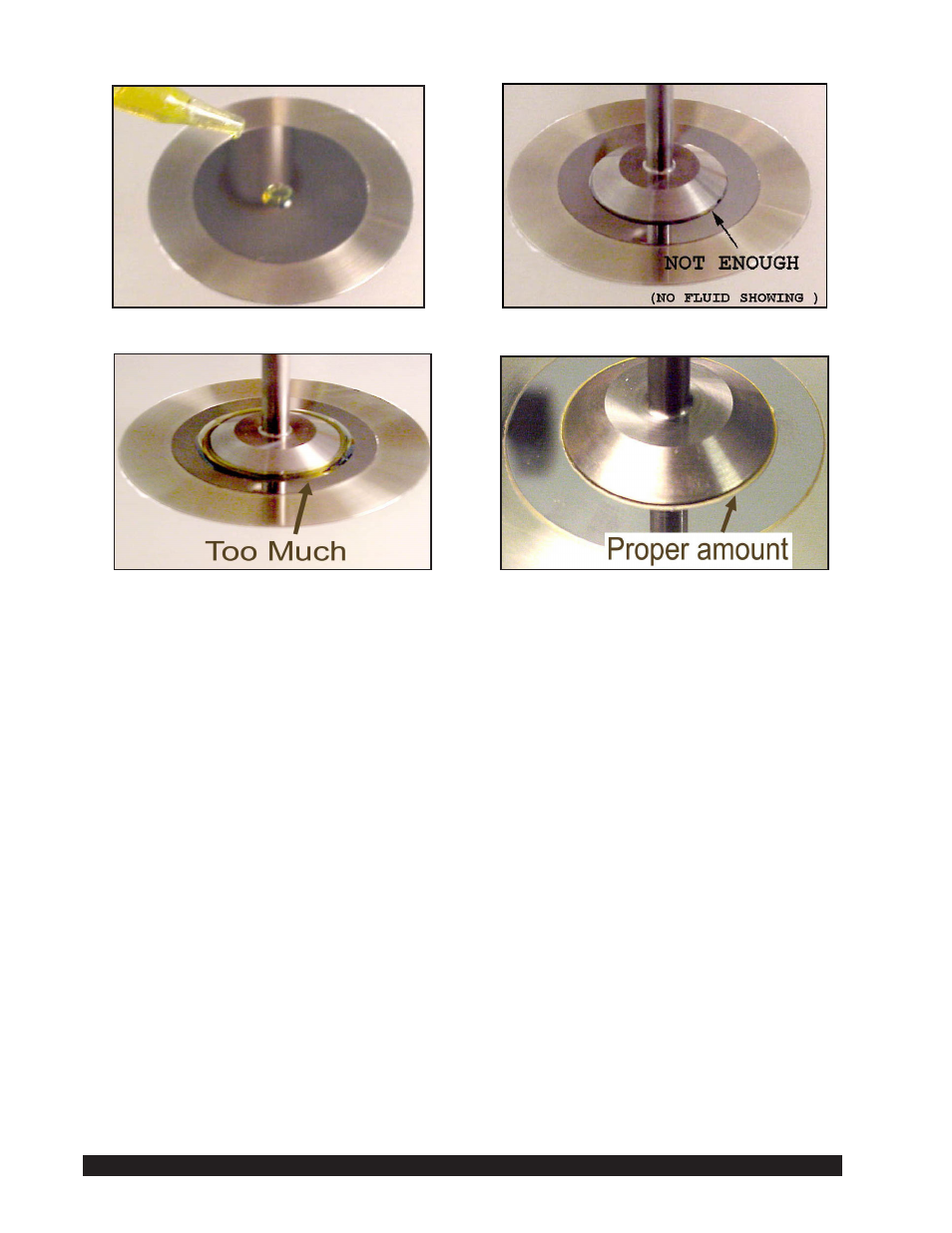

Figure III-1a

Figure III-1b

Figure III-1c

Figure III-1d

4. Run a viscosity test and record the viscosity value when the reading has stabilized.4. Run

a viscosity test and record the viscosity value when the reading has stabilized.

5. Compare the recorded viscosity to the actual value of the standard and verify that it falls

within the accuracy limits stated in Tables III-3 and III-4.

6. If the test fails, repeat again to make sure that every step was performed correctly. If the

test fails again, perform a cone calibration according to the procedure in Section III.4.