Operator’s manual – ANKOM TDF Dietary User Manual

Page 72

Operator’s Manual

pg. 72

Rev E 12/2/14

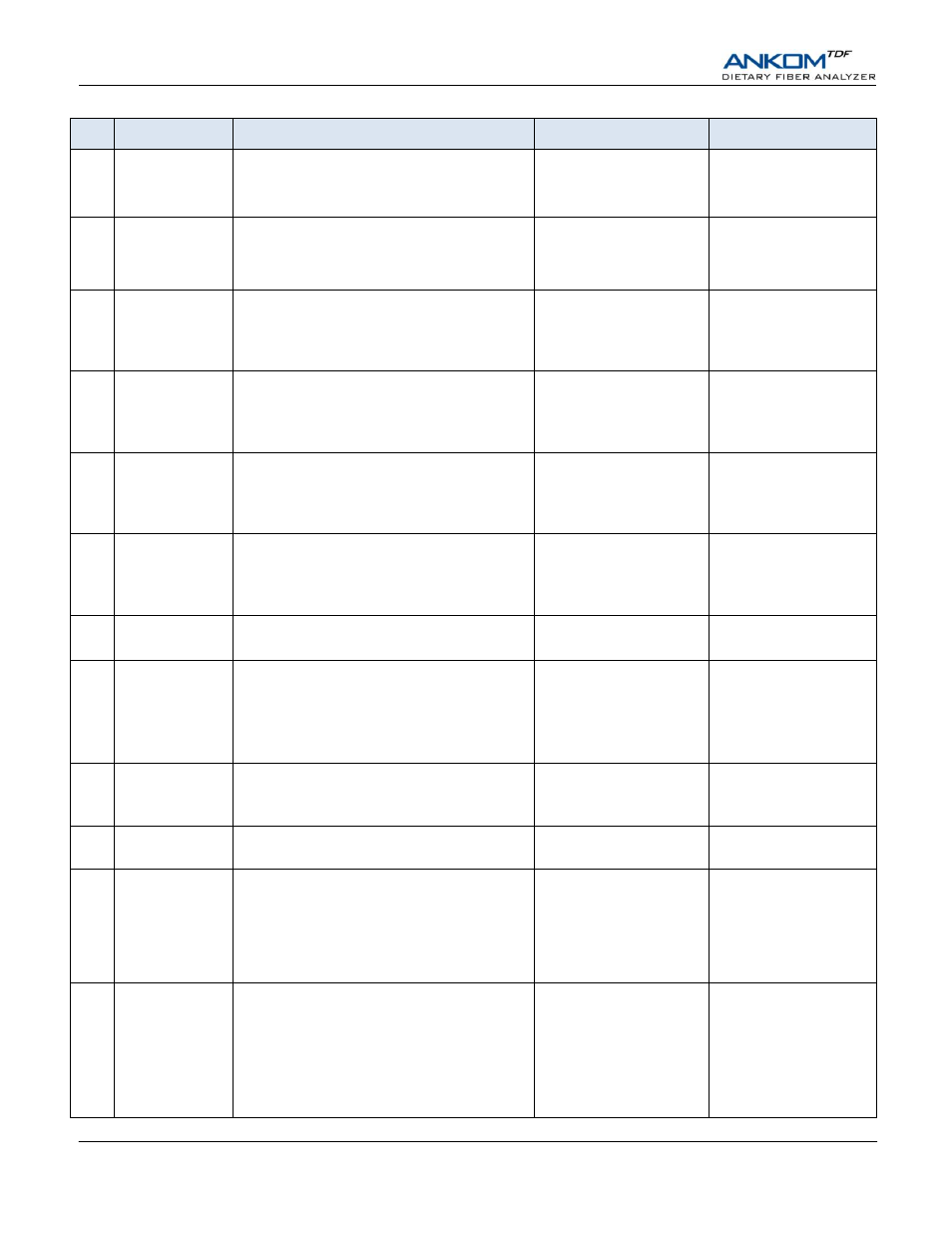

#

Name

Description

Result

Correction

E4

In-line Heater

Over Temp

The device that heats the fluid before

delivery is reporting a temperature that is

higher than the specified range.

In-progress processes are

aborted.

Run diagnostics.

Replace sensor or

heater.

E5

Paddle Heater

Under Temp

One of the Paddle Sensors is reporting a

temperature lower than the specified range.

IDF process continues.

SDF process unaffected.

Run diagnostics.

Replace Paddle Bar

assy (TDF24).

E6

In-line Heater

Under Temp

(IDF Amylase

Phase)

The device that heats the fluid before

delivery is reporting a temperature that is

lower than the specified range for the

Amylase phase.

IDF process continues.

SDF process unaffected.

Failed heater is disabled.

Run diagnostics.

Replace sensor or

heater.

E7

In-line Heater

Under Temp

(IDF Water

Rinse)

The device that heats the fluid before

delivery is reporting a temperature that is

lower than the specified range for the IDF

Water Rinse phase.

IDF process continues.

SDF process unaffected.

Failed heater is disabled.

Run diagnostics.

Replace sensor or

heater.

E8

In-line Heater

Under Temp

(SDF EtOH95

delivery)

The device that heats the fluid before

delivery is reporting a temperature that is

lower than the specified range for the SDF

EtOH95 Delivery phase.

IDF process unaffected.

SDF process continues.

Failed heater is disabled.

Run diagnostics.

Replace sensor or

heater.

E9

In-line Heater

Cooling Failure

The device that heats the fluid before

delivery is reporting a temperature that is

higher than the specified range for the Water

Cooling phase.

In-progress processes are

aborted.

Run diagnostics.

Replace sensor or

heater.

E10

High Line

Pressure

The pressure in one or more of the delivery

tubes is higher than the specified values.

In-progress processes are

aborted.

Check for plugged tube

or replace output valve.

E11

Low N

2

Input

Pressure

The pressure at the input port is lower than

the specified range.

In-progress processes are

frozen in time.

The mixer is stopped.

The N

2

filter is disabled

until fault is corrected.

Check that N

2

supply is

connected and working.

E12

High N

2

Input

Pressure

The pressure at the input port is higher than

the specified range.

Fault is reported.

All in-progress processes

continue.

Adjust high pressure

regulator gauge on the

instrument to 50psi.

E13

Tubing Failure

At least one of the pump tubes has broken

OR one of the output valves is not closing.

In-progress processes are

aborted.

Replace pump tubing or

repair output valve.

E14

Empty

Chemical

Container

The instrument detected that one or more

chemical containers are empty.

A message is displayed.

User can choose to retry,

override, or abort.

Override will prevent the

error message for the rest

of the run.

Fill the associated

container.

E15

Supply Line

Plugged

The instrument detected that one or more

chemical supply lines are plugged or the

associated valves are stuck in the closed

position.

A message is displayed.

User can choose to retry,

override, or abort.

Override will prevent the

error message for the rest

of the run.

Ensure that the supply

line connector is fully

engaged in the top of

the container, and check

for a clogged filter.

Contact ANKOM for

assistance.