Installation maintenance and cleaning, 4 descaling, 5 checking valves – STIEBEL ELTRON Accelera 300 User Manual

Page 22

22

| ACCELERA® 300 HEAT PUMP WATER HEATER

WWW.STIEBEL-ELTRON-USA.COM

INSTALLATION

MAINTENANCE AND CLEANING

15.4 Descaling

» Close the shut-off valve in the cold water supply to the tank.

» Draw water from the tank to relieve the pressure inside the

water heater.

CAUTION :

Risk of electric shock

Use copper conductors only

26

_03

_01

_102

5

3

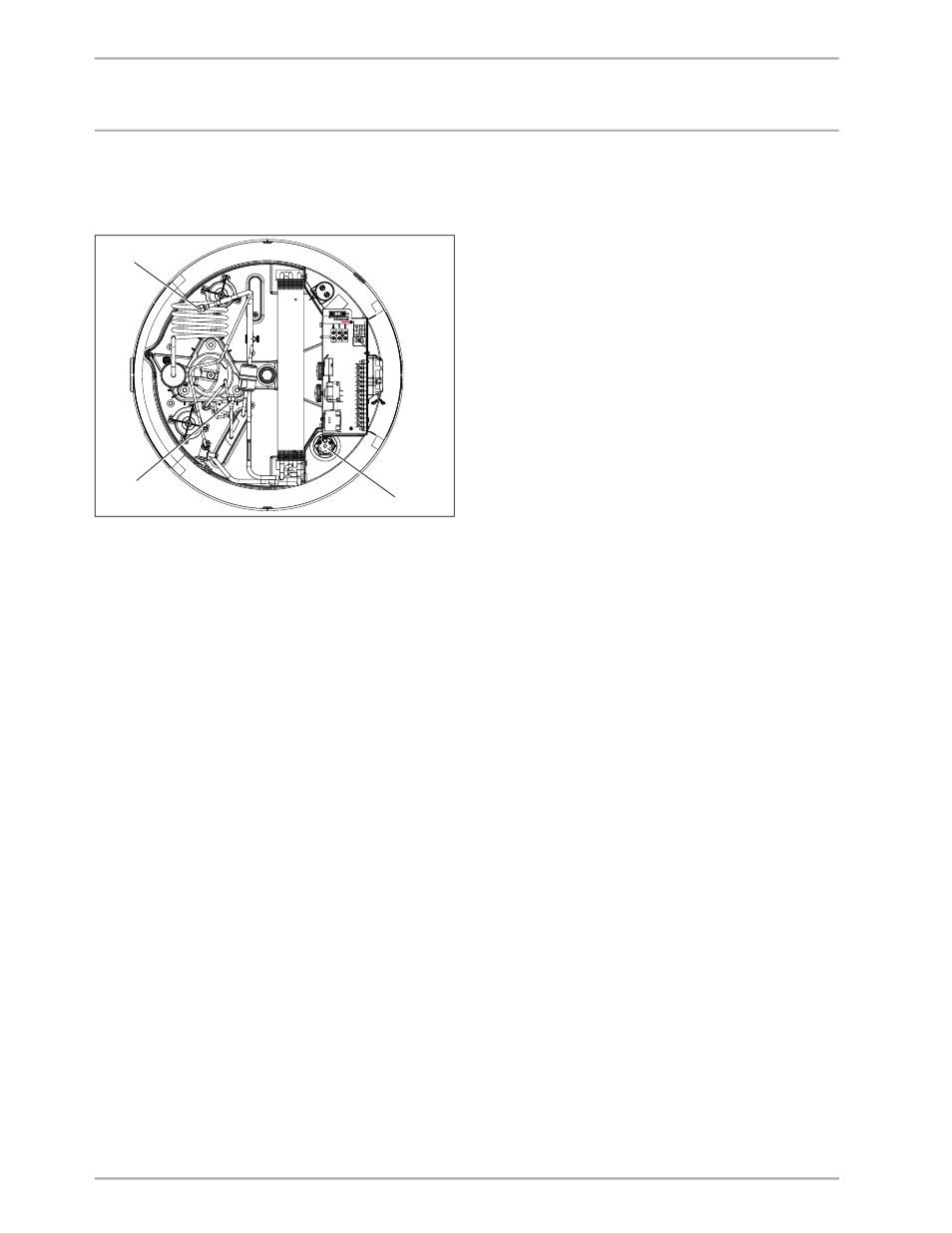

1 Low pressure fill port

2 High pressure fill port

3 Booster heater flange

» Unscrew the booster heater flange and remove element.

» Immerse scaled sections of the heater element into a

descaling liquid (for example citric acid), until the limescale

has dissolved.

» Flush the descaling liquid (white vinegar is another example)

off and allow the immersion heater element to dry.

15.5 Checking valves

15.5.1 Safety valve (on-site provision)

For reasons of safety, it is necessary to check the T&P valve for

proper function from time to time.

» Crack open the safety valve until a full jet of water is

discharged.

» Close the safety valve when the check is complete.

How quickly limescale builds up depends on the local water quality

and the hot water temperature. As your local licensed installers

are familiar with your local water quality, let them determine the

timing of the next service.

15.5.2 Pressure reducing valve (on-site provision)

» Check the on site pressure relief valve for function. If

required, replace the valve.

15.5.3 Checking refrigerant levels

» When checking refrigerant levels at fill ports be sure to use

new crush washers (supplied with unit).

1

2