Assembly of the throttle linkages, Adjusting the engine control linkages, Assembly of the front shocks – OFNA Racing Jammin X1 CRT RTR User Manual

Page 20

94033

3x3mm

Set Screw

Fuel Tube

10769

Servo Horn

Adapter

41

Step 1

Step 2

..........X4

94033

3x3mm

Set Screw

94033

3x3mm

Set Screw

30802

Throttle

Slider

94033

3x10mm

Hex Screw

10300

Alum

Stopper

10300

Alum

Stopper

40663

2X68mm

Rod

30531

Throttle

Spring

30802

Throttle

Ball End

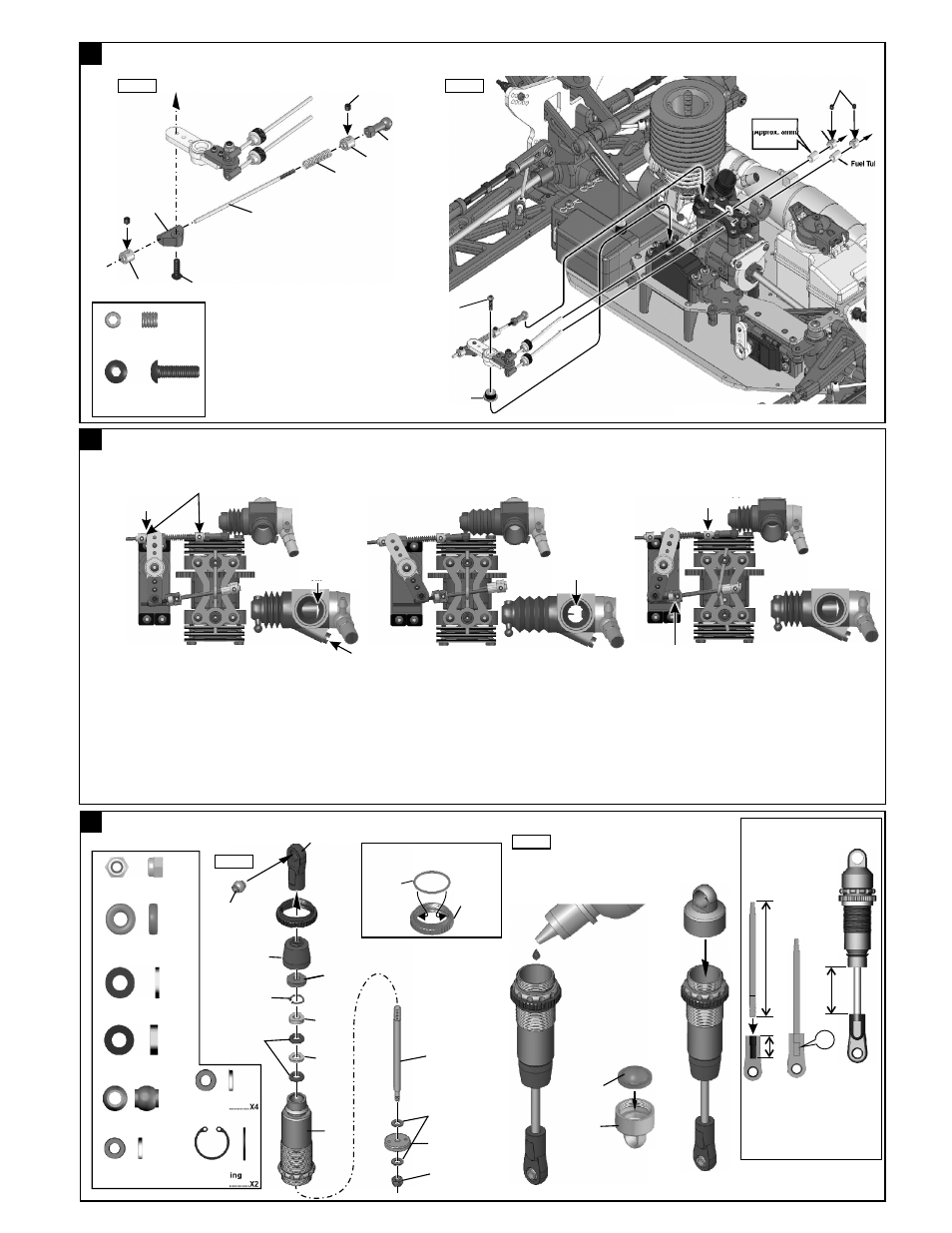

ASSEMBLY OF THE THROTTLE LINKAGES

94003

3X10mm

Hex Screw

..........X1

15

94033

3x3mm

Set Screw

10300

Alum

Stopper

Fuel Tube

Approx. 8mm

* Use the screw

provided with

your servo .

42

ADJUSTING THE ENGINE CONTROL LINKAGES

Approx. 1mm gap

Carburetor is

Opening fully

10300 Alum. Stopper

10300 Alum Stopper

Approx. 0.5mm

(Neutral)

(Throttle High)

(Brake)

Turn on the Transmitter then Receiver and set the

Engine Control Servo Trim to the neutral position.

Adjust the idling adjusting screw on the Carburetor

to be open approx. 1mm gap.

Idling adjusting

Screw

Adjust both of the #158 Engine Control and Brake linkage

accordingly.

Adjust the Engine while it is not running.

Adjust the Servo-Horn mounting position for the

Carburetor to be full open.

Change the pivot mounting position on the servo

horn in case the Carburetor is not opening fully or

if it is opening excessively. Or if available on the

Transmitter, adjust the Throttle high end point.

Adjust so the brakes work smoothly.

If the brakes apply too much or not enough,

adjust 30800 accordingly. Or if available on the

Transmitter, adjust the High-End Brake

adjustment.

Adjust 30800 to Change the front or Rear Brake.

30800 Alum. Adjust Nut

.

40090

2.6x5mm

Washer

..........X2

40090

7mm C-Ring

..........X4

Step 1

* Make 2 Shocks for the front.

45

ASSEMBLY OF THE FRONT SHOCKS

40634

Spring

Adjuster

40636

15x1 O-Ring

Fit the o-ring into groove before

assembly.

..........X4

...X2

....X2

40090

2mm Washer

40090

1mm Washer

40090

3.5mm

O-Ring

40090

2.6x5mm

Washer

......X2

2.5mm Nylock Nut

....X2

40643

Shock Plastic

Ball End

(Long)

40090

7mm

C-Ring

40633

Shock Cap

40090

1mm

Washer

40090

2mm

Washer

40640

Pressure Top

40638

Shock Piston

(1.6mm x 2 )

2.5mm

Nylon Nut

2.6x5mm

Washer

40054

Shock Shaft

(Front)

Step 2

30411

6mm Ball End

*fill the shocks

with oil.

40090

3.5mm O-Ring

....X4

40632

Shock

Body

40637

Dust Felt

40635

Shock Shaft

Dust Covers

30411

6mm Ball End

OK

2

8

m

m

5

6

.7

m

m

CORRECT SHOCK ASSEMBLY

Carefully screw the shock shaft into

the bottom of the plastic ball end

untill the distance between

the ball end and the shock body is

28mm

for the front .

N.B. Do not over tighten as the plastic

will strip.

1. Pull down piston and

pour oil into the shock

cylinder.

2. To remove air bubbles

slowly move the piston

up and down.

3. Pull down piston

attach cap loosely

slowly push the

piston up almost to

the top shock oil

will overflow then

tighten cap.

* Do not overtighten

the 2.5mm nylon nut.