Metalfab Continuous Batch Controller User Manual

Page 7

Metalfab, Inc.

04/22/05

- 7 °©

Batch Counter button. The batch counter enables the controller to count the number of batches

produced. The operator may enter the desired number of batches to run on the screen. When the

batch counter reaches the number of batches to run the controller will stop batching until the

reset button is pressed, clearing the batch counter. The reset button and the set desired number of

batches button are located on the batching screen. To display the batching screen press the Run

Feeder button from the main menu.

The Slow Fill Amount may be toggled between Fixed or Optimized. When set to fixed,

the Slow fill amount will remain the same from batch to batch. The amount of product to

dispense at the slow speed can be entered on the Batch Setup Screen from the main menu. If this

parameter is set to Optimized the controller will automatically adjust the amount of product

dispensed at slow speed to the minimal amount needed to still achieve accurate stopping weights.

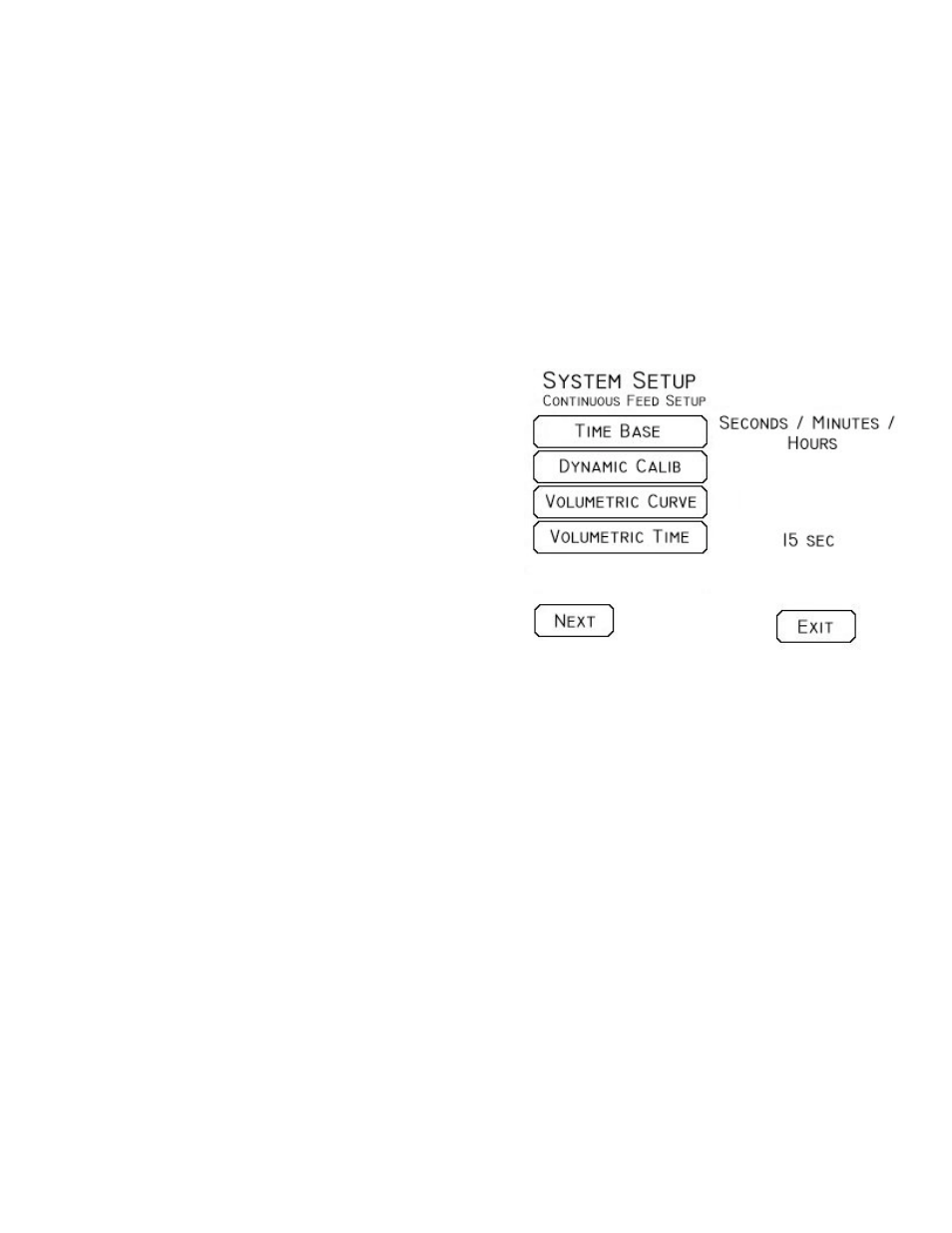

Continuous Setup (System Setup Menu)

If the system type is specified to be of

Continuous type, the Continuous Setup button is

enabled. The continuous feed setup menu allows the

configuration of parameters pertaining to the

continuous feed rate feature of the BC623 controller.

Pressing the Time Base button toggles the

time base between Second, Minutes, or Hours. The

time base is the unit of time the controller uses to

enter and display rate data. If Hours is selected, the

operator must enter the desired rate set point in Lbs

(or Kgs) per Hour. The controller will then display

the current feed rate in Lbs per Hour, and display the

stored history rates in Lbs per Hour. Similarly the

BC623 will display data in Lbs (or Kgs) per Minute, or per Second.

When a feeder system is initially setup, a dynamic calibration must be performed. All

feeders behave differently when in motion. Screw feeders vary depending on screw size, blade

pitch, and RPM. Belt feeders vary in similar ways. Performing a dynamic calibration accounts

for these variations. The dynamic calibration process runs the feeder at varying feed rates to

determine its characteristics. A dynamic calibration requires a supply of product, and a suitable

catching container. Performing a dynamic calibration also requires that the feeder be run. Make

certain that all feeder safety precautions have been met and that it is safe to turn on the feeder

prior to performing a dynamic calibration. To start the dynamic calibration press the Dynamic

Calib button. The BC623 will run the feeder at decreasing speeds from 100% to 10%, and build

a volumetric lookup table. This table will then be used to determine an appropriate starting value

when the feeder is turned on before switching to gravimetric mode.

When the Volumetric Calibration is complete, the Volumetric look up table may be

displayed by pressing the Volumetric Curve button. The Volumetric data collected during

calibration will be displayed on a line graph.

In the continuous feed rate mode, the BC623 dispenses product volumetrically at startup.

The amount of time the controller stays in volumetric mode before switching to Gravimetric

mode is specified by the Volumetric Time parameter. This value should be set high enough to

allow a stable flow of product to be leaving the feeder before gravimetric control begins.