System operation – Metalfab Continuous Batch Controller User Manual

Page 2

Metalfab, Inc.

04/22/05

- 2 °©

Ver 2.9

January 2002

This system was designed to control a product feeder in one of two different modes. It may be used as a

batch controller, or as a continuous feed controller. The BC623 may be used with either a gain in weight system or

a loss in weight system. The BC623 utilizes a touch screen interface for operator input and mechanical buttons for

frequently used functions. The BC623 will store a batch history when used in batching mode, a rate history when

used in continuous mode. The stored data may then be displayed on a line graph giving the operator a visual

indication of the system°Øs performance. The BC623 provides a 0 to 10 V or a 4 to 20 mA analog output to control

the connected product feeder. Also provided, are contact closures for remote discrete start and stop commands. A

second analog output may be used to remotely monitor the currently displayed scale weight. After initial setup is

complete, the BC623 may be used to dispense batches of a set amount, or to continuously dispense product at a set

rate.

System Operation

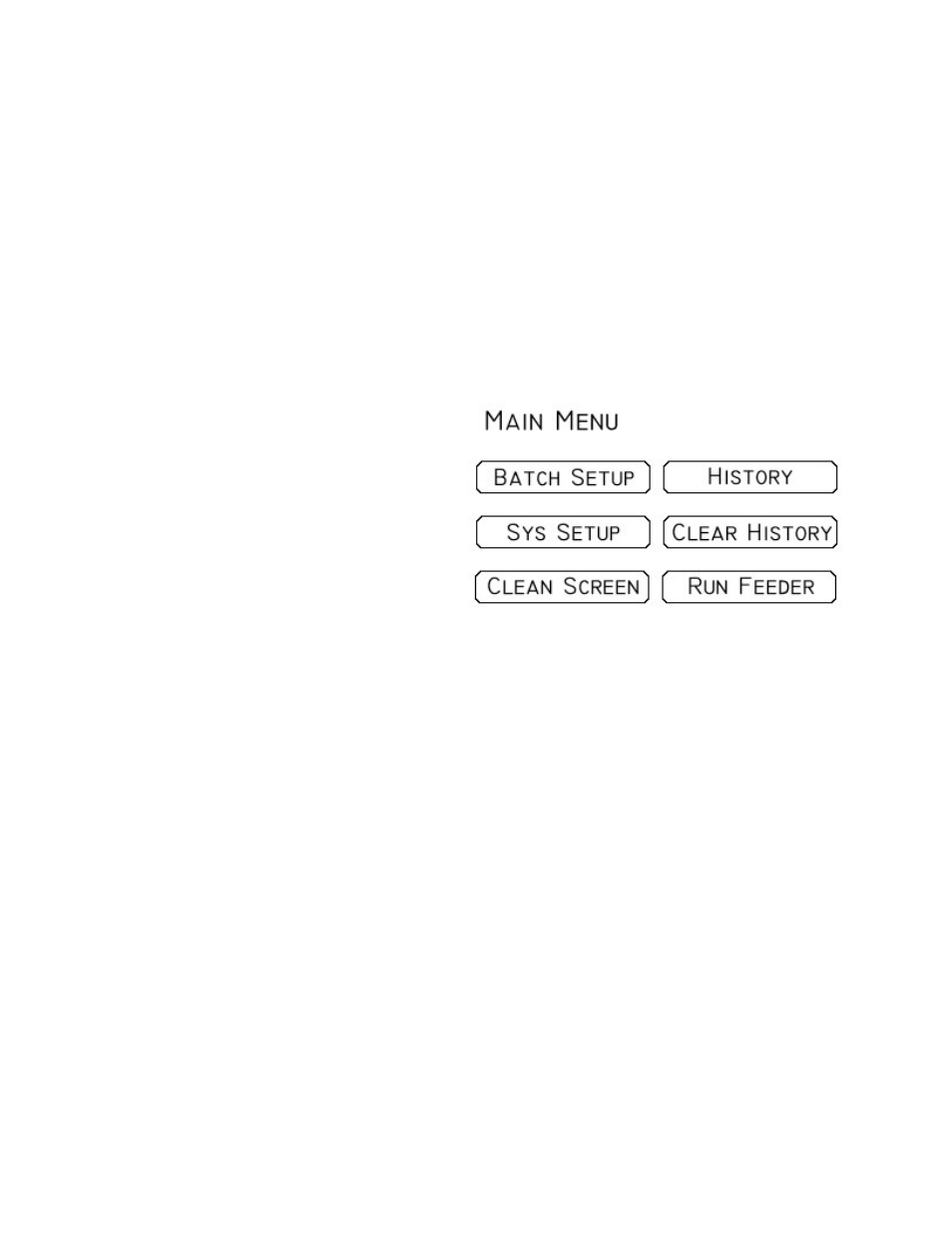

Main Menu

After the initial startup sequence has

completed, the main menu will be displayed

The operator may select any of the displayed

options by pressing the appropriate button. If

the system is set to operate in batching mode

there is the additional Batch Setup button. If

the system is set to operate in continuous

mode, the Batch Setup button is omitted.

Pressing the batch setup button allows the

operator to enter parameters relevant to the

batching process. The Sys Setup button

allows the operator to configure the system

setup parameters, and to perform operations such as calibration. The Clean Screen button

provides a safe place for the operator to wipe the screen without inadvertently pressing a button.

The History button displays either the batch history or the rate history depending on which mode

of operation is selected. The Clear History button, as the name implies, clears the stored history.

The last button, Run Feeder, readies the system to begin dispensing product.