Metalfab Continuous Batch Controller User Manual

Page 5

Metalfab, Inc.

04/22/05

- 5 °©

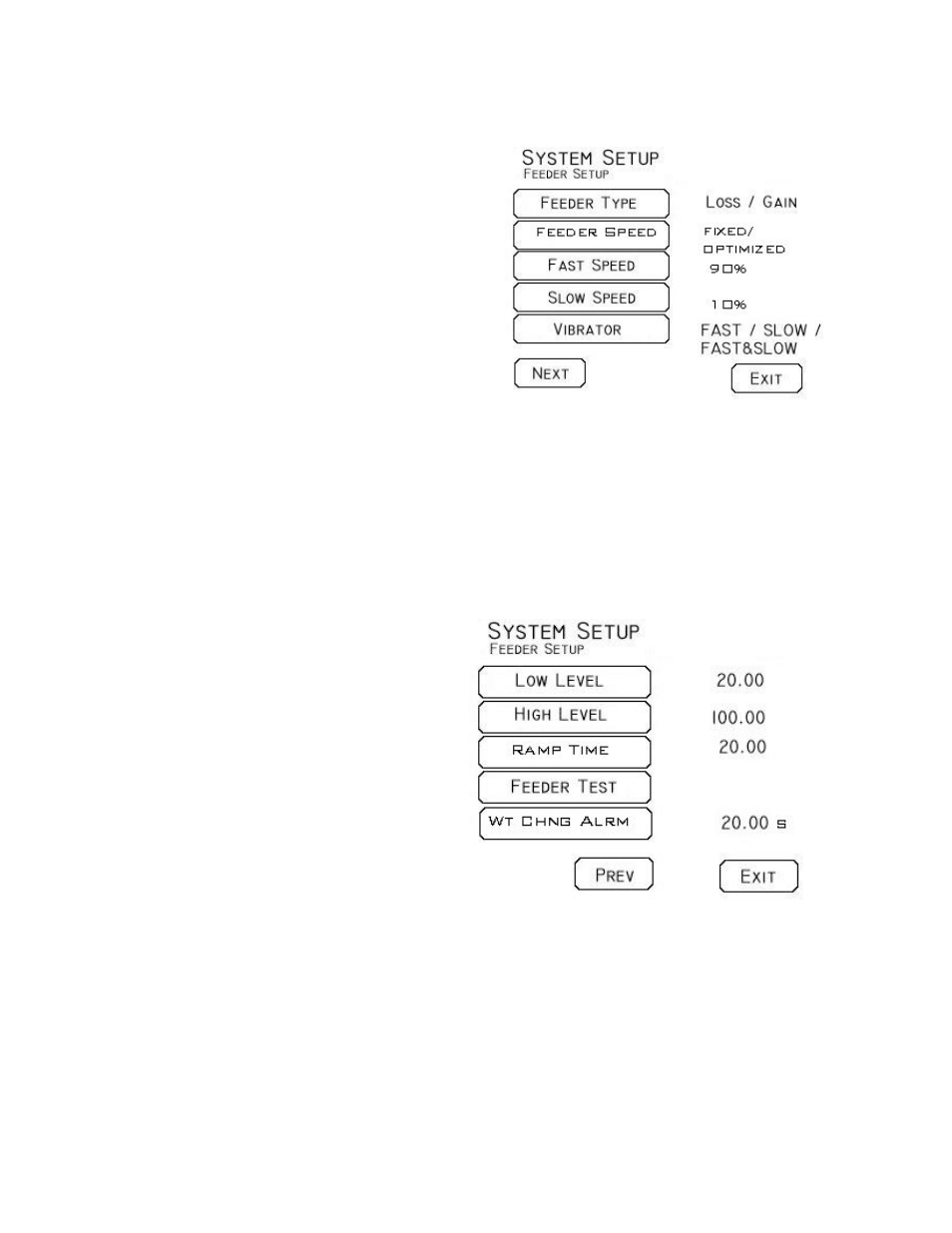

Feeder Setup (System Setup Menu)

The Feeder Setup menu allows the

modification of the feeder parameters. The

Feeder type may be selected as either Loss or

Gain. If the feeder is setup so that when the

feeder is running, product is leaving the scale,

then this parameter should be set to Loss. If the

feeder setup is such that when the feeder is

running product is being added to the scale, this

parameter should be set to Gain.

The Feeder Speed option may be set to

either Fixed or to Optimized. When set to fixed

the feeder speed will remain constant when

running at fast speed. If this parameter is set to optimize, then the controller will automatically

adjust the feeder speed until the fast speed set point optimizes product throughput.

The Fast Speed value sets the percentage of the output sent to the feeder when running at

the fast speed. This option is only available when the controller is being used in the batching

mode. The Slow Speed is the speed to which the feeder is switched when the amount to dribble

weight has been reached.

The Vibrator option designates when the feeder vibrator is active. The vibrator output

may be set to run when the feeder is running at fast speed only, slow speed only, or at both fast

and slow speeds.

The Next button displays additional

options. The Low Level option allows the

operator to enter the low level weight to

trigger a feeder refill. When the weight in the

feeder is below the low level set point, and a

batch is started, or the BC623 is continuously

feeding product, the feeder refill signal will

be issued. The refill signal will stay active

until the feeder has accumulated weight up to

the High Level. The automatic refill feature

would typically be used with Loss in weight

systems only.

The Feeder Ramp Time parameter

sets the time in seconds that the feeder will take to reach the Fast speed set point when starting.

This option is provided to allow a more controlled startup when used with motor drives having

no such feature. If the motor drive used to control the feeder has ramp up features, it is

recommended that the Ramp Time parameter be set to 0 and the innate drive features be utilized.

The Feeder Test button allows manual control of the feeder. This option allows the

operator to enter the desired output as a percentage of full speed and to start and stop the feeder.

This feature may be used for manual control purposes, or to trouble shoot a problematic feeder.

The Weight Change Alarm sets the number of seconds the controller allows to pass

without seeing a change in the weight before setting the no weight change alarm. The controller

monitors the changing weight whenever the feeder is running. If the time specified in this

parameter passes with no change in weight the alarm is set and an audible chirp is emitted.